Хорошее качество машина для гранулирования биомассы древесных пеллет под давлением

- Категория: Agricultural Machinery & Equipment >>>

- Поставщик: Jiangsu,Kingwood,International,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.43 $* | 0.74 $* |

| Aug-16-2025 | 0.35 $* | 0.77 $* |

| Jul-16-2025 | 0.0 $* | 0.86 $* |

| Jun-16-2025 | 0.84 $* | 0.86 $* |

| May-16-2025 | 0.86 $* | 0.96 $* |

| Apr-16-2025 | 0.52 $* | 0.13 $* |

| Mar-16-2025 | 0.25 $* | 0.35 $* |

| Feb-16-2025 | 0.65 $* | 0.2 $* |

| Jan-16-2025 | 0.93 $* | 0.73 $* |

Характеристики

Specification

item | value |

Applicable Industries | Manufacturing Plant |

Showroom Location | None |

Condition | New |

Place of Origin | China |

Brand Name | Kingwood |

Type | Ring die for feed mill |

Weight | 20kg |

Warranty | 1 Year |

Key Selling Points | High-accuracy |

Marketing Type | New Product |

Machinery Test Report | Provided |

Video outgoing-inspection | Provided |

Warranty of core components | 1 Year |

Core Components | Other |

Max. Capacity | Consultable |

Product Description

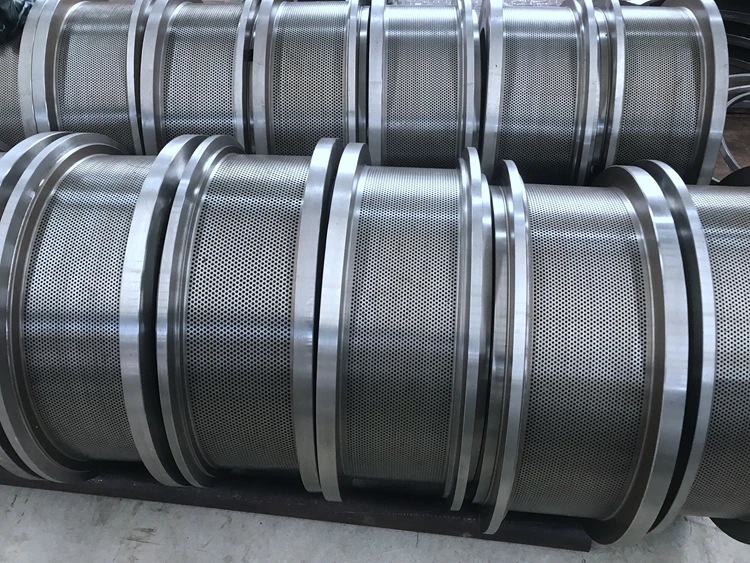

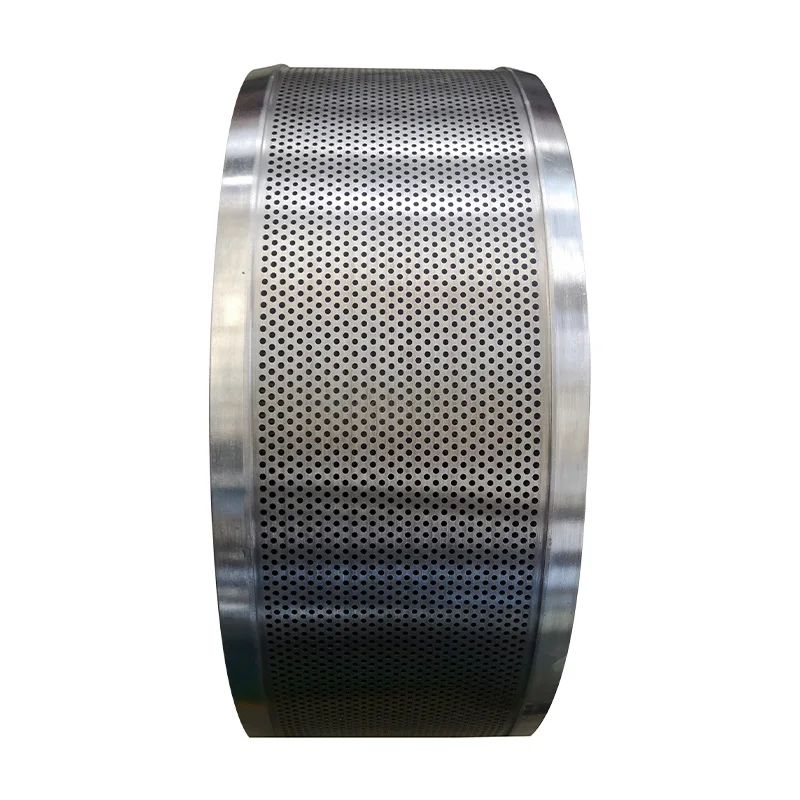

What is ring die?

Our company adopts high-quality steel, CNC deep-hole drilling machines, vacuum quenching furnaces and other advanced equipmentand unique processes; The problems of uneven particle length, high pulverization rate, and long running-in time; greatly improve production efficiency, improve particle quality, improve yield, and reduce production costs.

Features

1. The surface finish of the ring molding granule hole is high, the hole distribution is uniform, and the hardness is high.

2.The running-in time is short, the material is discharged smoothly, and no flushing is required (except for those with a diameter of 0.8-2.0). It can be directly loaded into the granulation machine, and the maximum hourly output can be achieved after running for 2 hours.

3. The pellets have good shape, good finish, high uniformity, low powder content and no material rejection.

4. The hourly output is high and the service life is long. The hourly output and total output of the ring die of the same

specification are significantly higher than the level of the same industry. 5. Energy saving. The current is stable and the power consumption is low. 6. Light weight, easy to load and unload.

3. The pellets have good shape, good finish, high uniformity, low powder content and no material rejection.

4. The hourly output is high and the service life is long. The hourly output and total output of the ring die of the same

specification are significantly higher than the level of the same industry. 5. Energy saving. The current is stable and the power consumption is low. 6. Light weight, easy to load and unload.

Ring die processing

Preparing→Forging→Rough lathing→Drilling→Countersinking→Screw holes→Splining→Heat treatment→Polishing→fine lathing→HRC testing→Brushing oil→Checking→Packaging →putting ingtostorage

Material:

It is made of stainless steel and 42CrMo alloy steel. And the surface is carburized. This gives it the characteristics of

corrosion resistance and wear resistance.

corrosion resistance and wear resistance.

Structure:

The structure of the feed inlet is a release stepped hole. Compared with other straight holes, the raw material enters the ring

die more easily, thus ensuring the working efficiency of the granulator. With a thicker ring die, the effective hole depth is

increased.

die more easily, thus ensuring the working efficiency of the granulator. With a thicker ring die, the effective hole depth is

increased.

High compression ratio:

Compared with the flat die used in the flat die pellet machine, the ring die has a higher effective hole depth. The material is

compressed in the ring die for longer time and distance, so the pellets produced by the ring die pellet machine have the

characteristics of high compression ratio.

The benefit of high compression ratio makes the nutrient density of feed pellets greater and can provide more nutrition for

animals. The calorific value of biomass particles can be made larger, and more heat energy can be provided.

compressed in the ring die for longer time and distance, so the pellets produced by the ring die pellet machine have the

characteristics of high compression ratio.

The benefit of high compression ratio makes the nutrient density of feed pellets greater and can provide more nutrition for

animals. The calorific value of biomass particles can be made larger, and more heat energy can be provided.

For Biomass Pellet Mill

The benefit of high compression ratio makes the nutrient density of feed pellets greater and can provide more nutrition for

animals. The calorific value of biomass particles can be made larger, and more heat energy can be provided.

animals. The calorific value of biomass particles can be made larger, and more heat energy can be provided.

For Feed Pellet Mill

The ring die is one of the core components of the RICHI feed pelletizer and biomass pelletizer. Its function is to combine with the pressure roller to press the powdery raw materials into pellets.

Company Profile

ABOUT US

Jiangsu Kingwood Industrial Co., Ltd. (listed in National Equities Exchange and Quotations, stock code: 871765), located in Zhongguancun Industrial Park of Liyang City, Jiangsu Province, China. The company covers an area of more than 35,000㎡, with 30 million USD existing fixed assets. It is a high-tech enterprise which is dedicated to develop low-carbon, and renewable energy equipment and advanced feed mill industry.

Established in 1999, Kingwood has been dedicated in providing one stop solution in biomass engineering, animal feed engineering and spare parts business for our valued customers, and these services are including: consultation, design, manufacture, logistic, installation, commissioning, training, and after-sales service for biomass/feed production line.

Core value:

Use "customer and supplier win-win" as the management principle, and "long-term development" as the business purpose, work with domestic and foreign customers to promote each other and create a win-win situation.

Our mission:

A "blue" innovative company researching future energy/feed technology, creating a "green" responsible company with low-carbon recycling and environmental protection.

Spirit:

Pioneering spirit of "Exploring and Enterprising"

Inovative spirit of "Daring to be the first mover"

Striving spirit of "Honest and Hard-working"

Established in 1999, Kingwood has been dedicated in providing one stop solution in biomass engineering, animal feed engineering and spare parts business for our valued customers, and these services are including: consultation, design, manufacture, logistic, installation, commissioning, training, and after-sales service for biomass/feed production line.

Core value:

Use "customer and supplier win-win" as the management principle, and "long-term development" as the business purpose, work with domestic and foreign customers to promote each other and create a win-win situation.

Our mission:

A "blue" innovative company researching future energy/feed technology, creating a "green" responsible company with low-carbon recycling and environmental protection.

Spirit:

Pioneering spirit of "Exploring and Enterprising"

Inovative spirit of "Daring to be the first mover"

Striving spirit of "Honest and Hard-working"

Our Workshop

Our Advantages

Main Products

Packaging & Shipping

FAQ

Q1: Are you a factory or trading company?

A1: We are special trading company owned by our factory. And our factory located in Changzhou, China, with nearly 100 workers in total. We have over 20 years’ experience in industries

A1: We are special trading company owned by our factory. And our factory located in Changzhou, China, with nearly 100 workers in total. We have over 20 years’ experience in industries

Q2: How you guarantee your product quality?

A2: Kingwood is always pay attention to the production quality and quality improvement, in order to achieve the high quality to meet high demand, we build the most advanced manufacturing equipment and strictly control every production point, not only from the procurement of the raw material, spare parts processing, welding, but also the assembly to finished product delivery. All quality controls in key production process is implemented strictly in Kingwood

A2: Kingwood is always pay attention to the production quality and quality improvement, in order to achieve the high quality to meet high demand, we build the most advanced manufacturing equipment and strictly control every production point, not only from the procurement of the raw material, spare parts processing, welding, but also the assembly to finished product delivery. All quality controls in key production process is implemented strictly in Kingwood

Q3: How about the delivery date?

A3: We build no storage management system, so before you place orders, please contact our sales team, they will give you professional delivery solution according to the product / production line lead time

A3: We build no storage management system, so before you place orders, please contact our sales team, they will give you professional delivery solution according to the product / production line lead time

Q4: How about the technical support from Kingwood?

A4: Kingwood has built the full service system from pre-sales, installation & commissioning and aftersales service including preventive maintenance, corrective maintenance and training process. According to customer’s requirement, we can provide service both online and in customer’s jobsite. And we also have oversea engineers in some countries in South East Asia / CIS/ East Europe and Latin America area that are available to service you at any time.

A4: Kingwood has built the full service system from pre-sales, installation & commissioning and aftersales service including preventive maintenance, corrective maintenance and training process. According to customer’s requirement, we can provide service both online and in customer’s jobsite. And we also have oversea engineers in some countries in South East Asia / CIS/ East Europe and Latin America area that are available to service you at any time.

Q5: How about the guarantee period?

A5: One year after our product arrives customer’s jobsite but no longer than 18month from BL date.

A5: One year after our product arrives customer’s jobsite but no longer than 18month from BL date.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.