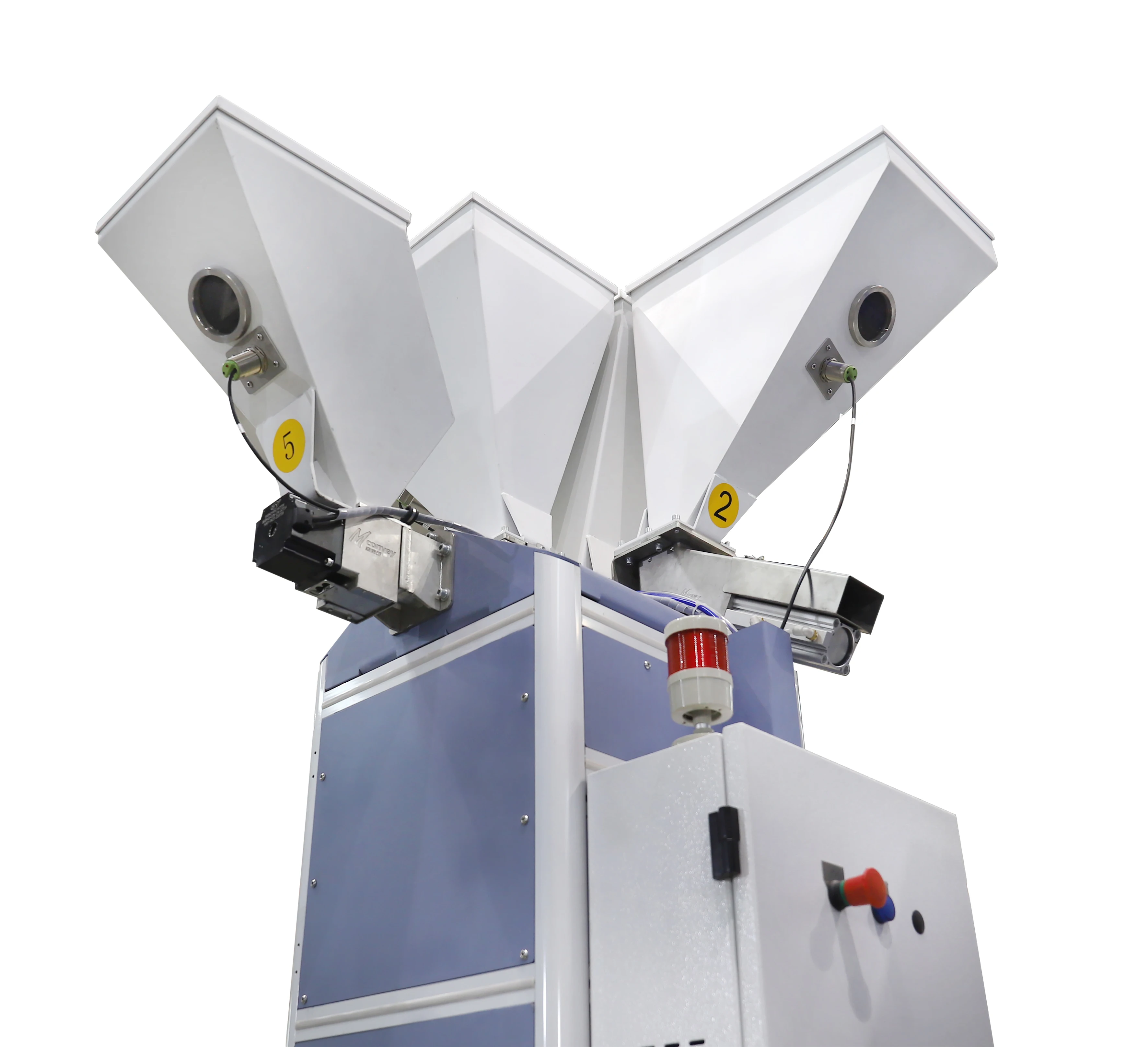

Китайский пластиковый рециркуляционный гранулятор блендер с контроллером веса новая гравиметрическая

- Категория: Plastic Raw Material Machinery >>>

- Поставщик: Guangdong,Liansu,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 6783.42 $* | 7122.24 $* |

| Aug-16-2025 | 6726.29 $* | 7062.90 $* |

| Jul-16-2025 | 5643.37 $* | 5925.41 $* |

| Jun-16-2025 | 6612.27 $* | 6943.0 $* |

| May-16-2025 | 5757.50 $* | 6045.7 $* |

| Apr-16-2025 | 6498.56 $* | 6823.12 $* |

| Mar-16-2025 | 6441.59 $* | 6763.32 $* |

| Feb-16-2025 | 6384.26 $* | 6703.9 $* |

| Jan-16-2025 | 6327.51 $* | 6643.38 $* |

Характеристики

Products Description

Model | Maximum processing capacity(kg/hr) | Batch processing capacity(kg) | Stirring motor(kw) | Compressed air(Bar) | Number of hoppers | Number of screw rods | Voltage | |||||||

LSGB-200-4R1 | 260 | 3 | 0.15 | 4-6 | 4 | 1 | 3¢, 380V, 50Hz | |||||||

LSGB-600-4R1 | 720 | 10 | 0.55 | 4-6 | 4 | 1 | 3¢, 380V, 50Hz | |||||||

LSGB-1200-4R1 | 1500 | 20 | 1.1 | 4-6 | 4 | 1 | 3¢, 380V, 50Hz | |||||||

LSGB-2000-4R1 | 2350 | 30 | 1.1 | 4-6 | 4 | / | 3¢, 380V, 50Hz | |||||||

LSGB-3000-4R1 | 3700 | 50 | 1.5 | 4-6 | 4 | / | 3¢, 380V, 50Hz | |||||||

LSGB-5000-4R1 | 4850 | 90 | 2.2 | 4-6 | 4 | / | 3¢, 380V, 50Hz | |||||||

Note: The above models are equipped with a support + storage hopper + material distribution station; PLC control, touch screen display; Siemens weighing sensor; The above models are only suitable for 3-6mm granules | ||||||||||||||

Mconvey provides overall solution for plastic material handling system:

1.Material storage system

2.Material drying&dehumitifing sytem

3.Dosing& weighing system

4.Compound & mixing system

5.Control system

2.Material drying&dehumitifing sytem

3.Dosing& weighing system

4.Compound & mixing system

5.Control system

If you want more details, please contact us

Products Detail display

Modular structure design.

A: Each component adopts modular assembly structure.And most of the parts are inter-changeable,like the hoppers, pneumatic valve gates. and screw feeding heard.

B: Most of components adopt quick disasembly design,which is convenient for material replacement

and cleaning.

B: Most of components adopt quick disasembly design,which is convenient for material replacement

and cleaning.

Casting component.

The key components are made by precison-moulding. like the valve gates.The support and installation part of the screw feeding head, which improve the performance and durability.

Great data storage and equipped with networking port .

-Up to 500 groups of fomulas can be stored

-The blenders are equipped wwith RJ45 Ethernet Communication port. which is convenient for date

networking.

-The blenders are equipped wwith RJ45 Ethernet Communication port. which is convenient for date

networking.

Mixing without dead zones.

Material bin is 45 degree inclined and the stirring device is smartly designed to cover all the corners, No dead zones and are well mixed.

Product Schematic diagram

Working principle:

* The signal from the control box is transmitted to the motor, and the motor starts operation to drive the screw rod to rotate through the coupling. * The color master batch in the hopper falls into the screw rod, and then is squeezed by the screw rod, and conveyed to the base by the screw rod. A weighing sensor is used to precisely control the output of the color master batch to realize the proportional addition of the color master batch, so as to achieve the purpose of accurately metering and conveying the color master batch.

Scope of application:

* Suitable for automatic proportioning and mixing of new materials, secondary materials, color master batches or additive

materials; * With the screw diameter of 12mm, 16mm or 20mm, and four models that provide different output of 0.1-50kg/h; *Suitable for extruder and injection molding machine, only a little wiring is required for switching, and its rotation speed is automatically adjusted with the processing speed of the extruder to maintain a fixed color master batch ratio.

* The signal from the control box is transmitted to the motor, and the motor starts operation to drive the screw rod to rotate through the coupling. * The color master batch in the hopper falls into the screw rod, and then is squeezed by the screw rod, and conveyed to the base by the screw rod. A weighing sensor is used to precisely control the output of the color master batch to realize the proportional addition of the color master batch, so as to achieve the purpose of accurately metering and conveying the color master batch.

Scope of application:

* Suitable for automatic proportioning and mixing of new materials, secondary materials, color master batches or additive

materials; * With the screw diameter of 12mm, 16mm or 20mm, and four models that provide different output of 0.1-50kg/h; *Suitable for extruder and injection molding machine, only a little wiring is required for switching, and its rotation speed is automatically adjusted with the processing speed of the extruder to maintain a fixed color master batch ratio.

Product display