Практичная и доступная линия по производству

- Категория: Toothpick Making Machines >>>

- Поставщик: Henan,Shuoman,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.44 $* | 0.60 $* |

| Aug-19-2025 | 0.19 $* | 0.15 $* |

| Jul-19-2025 | 0.43 $* | 0.73 $* |

| Jun-19-2025 | 0.44 $* | 0.32 $* |

| May-19-2025 | 0.48 $* | 0.96 $* |

| Apr-19-2025 | 0.0 $* | 0.14 $* |

| Mar-19-2025 | 0.61 $* | 0.10 $* |

| Feb-19-2025 | 0.54 $* | 0.55 $* |

| Jan-19-2025 | 0.21 $* | 0.66 $* |

Характеристики

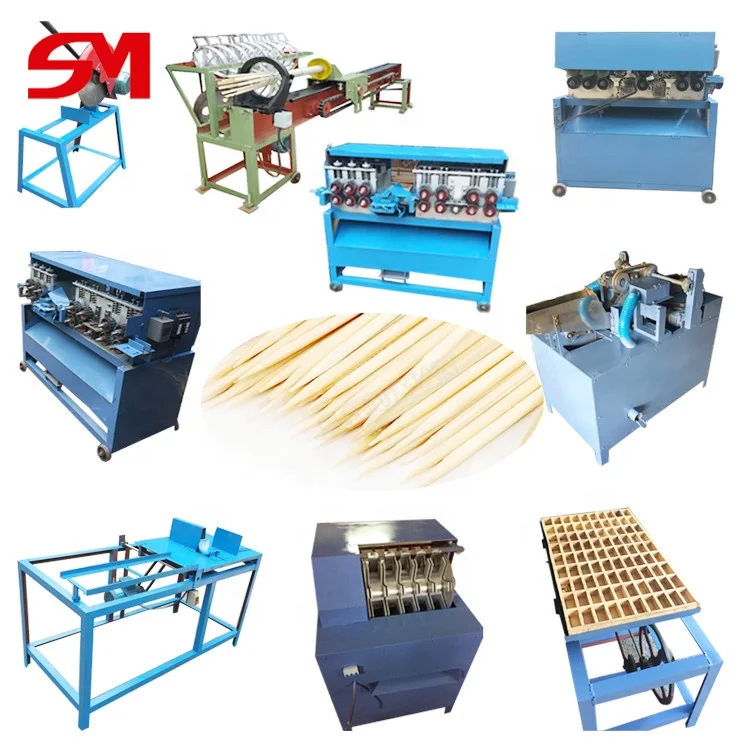

Hot Selling Practical And Affordable bamboo wood chipper toothpick chopstick making machine

Products Description

There are two kinds of raw materials for toothpick machine, one is bamboo and the other is wood. The following is the introduction of the two production lines corresponding to the two materials.

Advantage of toothpick machine/chopstick making machine:

1.The original bamboo - take the material sawing - open bamboo - section of the set wide open film - drawing - bleaching - drying - cut length - polished - finishing - sharpening - packaging.

2.More than 10 for a production line, the production of two pointed toothpicks, 8 hours of production 800,000, about 100 kg. Need to operate 4-6 employees, the use of industrial electricity 380v. An increase of Unit 9, the output doubled, then 1.6 million.

Features of toothpick machine/chopstick making machine:

1. Bamboo Sawing Machine: It is used to cut bamboo into certain length.

2. Bamboo Cutting Machine: This machine is used to split the bamboo into strips.

3. Fixed Width Slicer: Used for width and thickness setting and knot removing, separating green layer from yellow layer, ensures the surface quality of processed material.

4. Bamboo Stick Shaping Machine: This machine is used for making thick bamboo strip into thinner one.

5. Bamboo Stick Size Setting Machine: Special equipment for bamboo stick or wood stick fixed size cutting, especially for round stick size set.

6. Bamboo Toothpick Cutting Machine: Length setting for bamboo toothpick

7. Toothpick Polishing Machine: It is to make the surface of toothpicks more smooth.

8. Toothpick Finishing Machine: Dedicated equipment for tidying toothpicks. Through vibration, tidy the irregular toothpicks to achieve the effect of packaging.

9. Toothpick Sharpening Machine: Used for sharpening bamboo toothpicks.

10. Blade Sharpening Machine: Used for blade grinding.

Bamboo toothpick production line

10 sets are a production line that produces two pointed toothpicks. The output in 8 hours is about 800,000 sticks and about 100kg.

Requires 3 to 6 operating staff and uses industrial power 380v. Power consumption is about 10-12 degrees per hour.

Requires 3 to 6 operating staff and uses industrial power 380v. Power consumption is about 10-12 degrees per hour.

Wood toothpick production line

8 sets are a production line that produces two pointed toothpicks. The output in 8 hours is about 600,000 sticks. Requires 3 to 5 operating staff and uses industrial power 380v.

Product Paramenters

NO | Bamboo Toothpick Machines | Model | Power(kw) | Weight(kg) | Machine size(mm) | |||||

1 | Sawing machine (Bamboo) | DN-111 | 1.5 | 60 | 750*600*1300 | |||||

2 | Bamboo dissection machine | DN-102 | 3.0 | 530 | 3000*950*1200 | |||||

3 | Combined flakers | DN-103 | 3.0 | 260 | 1180*680*1100 | |||||

4 | Bamboo filament shaping machine | DN-104 | 9.1 | 400 | 1020*690*1050 | |||||

5 | Bamboo filament set-size machine | DN-105 | 0.75 | 75 | 800*700*900 | |||||

6 | Toothpick set-size machine | DN-114 | 2.75 | 140 | 900*700*950 | |||||

7 | Polishing machine | DN-80 | 1.5 | 110 | 1050*1050*1200 | |||||

8 | Toothpick neat machine | DN-113 | 0.55 | 65 | 1050*900*850 | |||||

9 | Tooth pick mincing machine(one side or two sides) | DN-268 | 1.65 | 160 | 950*650*1050 | |||||

10 | Multi-sharpen machine | DN-108 | 0.55 | 50 | 450*400*870 | |||||

NO | Wood Toothpick Machines | Model | Power(kw) | Weight(kg) | Machine size(mm) | |||||

1 | Wood flaker | DN-656 | 6.05 | 260 | 1050*680*1050 | |||||

2 | Wood filament shaping machine | DN-652 | 4.95 | 260 | 1050*680*1050 | |||||

PS: The last six machines of wooden toothpicks are the same as the last six machines of bamboo toothpicks | ||||||||||

Products Application

1.Usually every 100 kg of fresh (wet) bamboo, can produce diameter 2.0mm, 65mm long toothpick specifications of 10-13 million, about 13-16 kg dry finished toothpicks.

2. If users need to produce a head of a carved bamboo toothpicks, then replace the 9 machine (a sharpening machine), the same machine as a set of 10, 8 hours of production in 600000, increased 9 (a head of a sharpening machine), production doubled, 1.2 million.

2. If users need to produce a head of a carved bamboo toothpicks, then replace the 9 machine (a sharpening machine), the same machine as a set of 10, 8 hours of production in 600000, increased 9 (a head of a sharpening machine), production doubled, 1.2 million.

Details Images

Packaging & Shipping

PACKAGE:

Standard export carton or wooden case packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Standard export carton or wooden case packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Company Profile

Henan Shuoman Machinery Equipment Co.,Ltd is a modern firm integrating scientific research development production design and services.We manufacture food machinery that include wheat processing equipment,meat processing equipment,vegetable and fruit processing equipment, fried food equipment ,cold drink equipment in the market.

Why Choose Us

1.20 year experiences in manufacturing food machine.

2.Alibaba Assessed 6 years Gold Supplier.

3.100% QC inspection Before shipment.

4.OEM accept,Customized services offered.

5.Environment-friendly materials and technology.

6.24 hours technical supports and after sales services.

7.Factory price,High quality,Wholesale price,Fast delivery.

2.Alibaba Assessed 6 years Gold Supplier.

3.100% QC inspection Before shipment.

4.OEM accept,Customized services offered.

5.Environment-friendly materials and technology.

6.24 hours technical supports and after sales services.

7.Factory price,High quality,Wholesale price,Fast delivery.

Contact Us