Пивоваренное оборудование для пивоварни приготовления пива ресторанов баров 100 л

- Категория: Beverage & Wine Processing Machinery >>>

- Поставщик: Shandong,Carry,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 3299.24 $* | 3464.54 $* |

| Aug-19-2025 | 3271.16 $* | 3435.14 $* |

| Jul-19-2025 | 2744.33 $* | 2881.11 $* |

| Jun-19-2025 | 3216.19 $* | 3377.44 $* |

| May-19-2025 | 2800.78 $* | 2940.62 $* |

| Apr-19-2025 | 3160.12 $* | 3318.23 $* |

| Mar-19-2025 | 3132.0 $* | 3289.77 $* |

| Feb-19-2025 | 3105.96 $* | 3260.5 $* |

| Jan-19-2025 | 3077.40 $* | 3231.68 $* |

Характеристики

SPECIFICATION

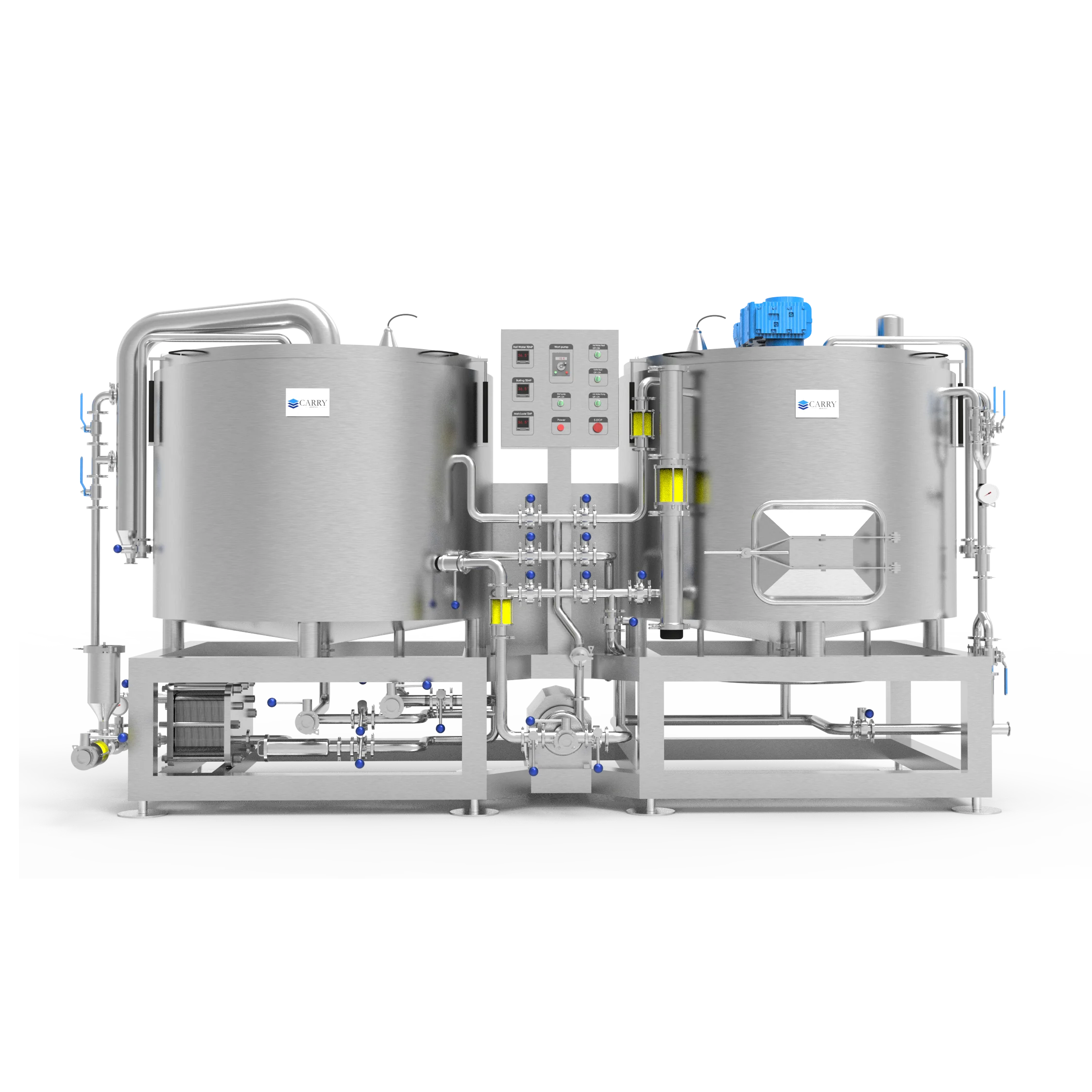

1 | Mash+Lauter Tank | 9 | Drain Pipe | ||

2 | Kettle+Whirlpool Tank | 10 | Wort Pump | ||

3 | VFD Motor&Reducer Equip with Rake Inside | 11 | Wort Balance Tank4 | ||

4 | Top Manway | 12 | Outdoor Condensing Unit | ||

5 | Sight Glass | 13 | Level Tube | ||

6 | CIP Arm | 14 | Plate Heat Exchanger | ||

7 | Vinasse Door | 15 | Yeast Adding Tank | ||

8 | Wort collection&Back flushing pipelines | 16 | Platform with stairs and guardrails | ||

Kettle/whirlpool tank(left)

1. Effective volume=500L, max volume=625L

2. Transparent glass manhole

3. Grain Raker with 0.75KW VFD Motor & Reducer & simple grain out device (mounted on top of lid)

4. Easy clean and detachable sparging spray ring

5. 360° coverage CIP spraying ball

6. Side mounted grain outdoor&grain chute, size=430*530mm

7. Professional designed SUS304 false bottom, milled gap: 0.7mm

8. Temperature probe (PT-100)

9. With balance Tank

10. With sight glass equipped on the wort back-flow pipeline

11. With all according piping & fittings included

12. With 3T/H Wort pump, VFD Control by PID control panel

13. Back flushing pipe & wort collection pipe under the Tank

2. Transparent glass manhole

3. Grain Raker with 0.75KW VFD Motor & Reducer & simple grain out device (mounted on top of lid)

4. Easy clean and detachable sparging spray ring

5. 360° coverage CIP spraying ball

6. Side mounted grain outdoor&grain chute, size=430*530mm

7. Professional designed SUS304 false bottom, milled gap: 0.7mm

8. Temperature probe (PT-100)

9. With balance Tank

10. With sight glass equipped on the wort back-flow pipeline

11. With all according piping & fittings included

12. With 3T/H Wort pump, VFD Control by PID control panel

13. Back flushing pipe & wort collection pipe under the Tank

Mash/Lauter Tun (right)

1. Effective volume=500L, max volume=830L

2. Transparent glass manhole

3. Build in 36 KW Electric Heating Elements

4. outdoor condensing pipe to prevent liquid back-flow

5. 360° coverage CIP spraying ball

6. Tangent whirlpool inlet

7. Temperature probe (PT-100)

8. With level tube outside of tank

9. With all according piping&fittings included

10. 2nd wort outlet port on the bottom

2. Transparent glass manhole

3. Build in 36 KW Electric Heating Elements

4. outdoor condensing pipe to prevent liquid back-flow

5. 360° coverage CIP spraying ball

6. Tangent whirlpool inlet

7. Temperature probe (PT-100)

8. With level tube outside of tank

9. With all according piping&fittings included

10. 2nd wort outlet port on the bottom

PRODUCTION DETAILS

OPTIONAL CONFIGURE

Fermentation tank

*360° spray ball equip with CIP arm

*Pressure gauge and Spunding Valve on CIP arm

*Sample Valve

*Temperature probe: PT-100

*Cooling jacket: Dimpled plate on cone and side

*Insulation layer: PU-thickness= 80mm.

*Design pressure 0.3MPa; Working pressure 0.15Mpa.

*100% high accuracy TIG welding.11. Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) *thickness: 2mm, Hairline; polishing

*Pressure gauge and Spunding Valve on CIP arm

*Sample Valve

*Temperature probe: PT-100

*Cooling jacket: Dimpled plate on cone and side

*Insulation layer: PU-thickness= 80mm.

*Design pressure 0.3MPa; Working pressure 0.15Mpa.

*100% high accuracy TIG welding.11. Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) *thickness: 2mm, Hairline; polishing

Bright Beer Tank

*360° spray ball equip with CIP arm

*Pressure gauge and pressure relief vavle on CIP arm

*Sample Valve and Carbonation Stone equipped on tank

*Temperature probe: PT-100

*Cooling jacket: Dimpled plate on cone and side

*Level Tube

*Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) thickness: 2mm, Hairline

polishing;

*Oval head&conical bottom, thickness: 3mm.

*Insulation layer: PU-thickness= 80mm.

*100% high accuracy TIG welding.

*Design pressure 0.3MPa; Working pressure 0.15Mpa.

*Pressure gauge and pressure relief vavle on CIP arm

*Sample Valve and Carbonation Stone equipped on tank

*Temperature probe: PT-100

*Cooling jacket: Dimpled plate on cone and side

*Level Tube

*Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) thickness: 2mm, Hairline

polishing;

*Oval head&conical bottom, thickness: 3mm.

*Insulation layer: PU-thickness= 80mm.

*100% high accuracy TIG welding.

*Design pressure 0.3MPa; Working pressure 0.15Mpa.

Hot Water Tank

*Top manway

*Pressure Relief Valve

*Temperature probe(PT-100)

*Level tube indicator

*Inner-Jacket(SUS 304), TH=3.0mm, pickling&passivating treated; External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate;

*Dish head (SUS 304)

*Insulation layer: PU-thickness=80mm

*100% high precision TIG welded joints

*4pcs x SUS304 heavy duty legs with leveling pad

*Pressure Relief Valve

*Temperature probe(PT-100)

*Level tube indicator

*Inner-Jacket(SUS 304), TH=3.0mm, pickling&passivating treated; External-Jacket(SUS 304), TH=2.0mm, ink wires drawing plate;

*Dish head (SUS 304)

*Insulation layer: PU-thickness=80mm

*100% high precision TIG welded joints

*4pcs x SUS304 heavy duty legs with leveling pad

Glycol water tank

* Level tube

* Insulated conical top and sloped bottom

*Glycol water inlet and outlet

*Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) thickness: 2mm, Hairline

polishing;

*Insulation layer: PU-thickness= 80mm.

*100% high accuracy TIG welding.

* Insulated conical top and sloped bottom

*Glycol water inlet and outlet

*Inner-jacket (SUS304) thickness: 3mm, pickling and passivating treated;External-Jacket(SUS304) thickness: 2mm, Hairline

polishing;

*Insulation layer: PU-thickness= 80mm.

*100% high accuracy TIG welding.

Industrial Chiller

*Internal compressor brand is USA Copeland.

*Copland vortex compressor, more durable, refrigeration effect

*Medium: Environmental protection refrigerants R404A

*Copland vortex compressor, more durable, refrigeration effect

*Medium: Environmental protection refrigerants R404A

PID Control System

1. SUS 304 Material cabinet

2. Installing style: wall-mounted

3. Temperature indicator of brewhouse & hot water tank

Pump & motor & rake reducer VFD Speed control & control

of fermenters & glycol tank & chiller

4. High quality electronic components, CE standard

5. Pump on/off control

6. High quality electronic components, CE standard

2. Installing style: wall-mounted

3. Temperature indicator of brewhouse & hot water tank

Pump & motor & rake reducer VFD Speed control & control

of fermenters & glycol tank & chiller

4. High quality electronic components, CE standard

5. Pump on/off control

6. High quality electronic components, CE standard

PLC Control System

1. SUS 304 Material cabinet

2. Working power: 380V, 50HZ, 3 Phase (optional: 220V, 60HZ, 1/3 Phase, 110V, 60hz, 1 Phase, Customized)

3. Siemens Control module, high precision HDMI touch screen,Schneider electric components;

4. Have memory space, support different mashing recipes;

5. Function of Temperature control curve, open source program,support functional development if needed;

6. Temperature indicator and control

7. Steam heating solenoid valve on/off control

8. E-Stop buttom

9. CE; UL; ISO Certificated

2. Working power: 380V, 50HZ, 3 Phase (optional: 220V, 60HZ, 1/3 Phase, 110V, 60hz, 1 Phase, Customized)

3. Siemens Control module, high precision HDMI touch screen,Schneider electric components;

4. Have memory space, support different mashing recipes;

5. Function of Temperature control curve, open source program,support functional development if needed;

6. Temperature indicator and control

7. Steam heating solenoid valve on/off control

8. E-Stop buttom

9. CE; UL; ISO Certificated

CIP

Disinfection tank(left)

*SUS304 Material Cone top & bottom *Thickness is 2mm

*Valves and fittings included

Alkali tank(right)

*Double layers, with 50mm PU insulation

*SUS304 Material Cone top & bottom *Thickness is 2mm

*Valves and fittings included

*Heating: 3KW electric heating tubes

*SUS304 Material Cone top & bottom *Thickness is 2mm

*Valves and fittings included

Alkali tank(right)

*Double layers, with 50mm PU insulation

*SUS304 Material Cone top & bottom *Thickness is 2mm

*Valves and fittings included

*Heating: 3KW electric heating tubes

AUXILIARY MACHINE

4&6&8 Head bottle filling machine

1.Dimension=2.73x0.85x2.20M, gross weight=245KG

2.Bottling capacity:320~420 pcs/h

3.Power supply: Single phase 110-240V 50/60Hz

4.Power consumption:200W 5.Beer Source 5. Pressure: 0.15Mpa

4.Power consumption:200W 5.Beer Source 5. Pressure: 0.15Mpa

6.CO2 Regulator Pressure range: 0.15-0.2Mpa 7.Siemens PLC 200 smart

8.Beer bottle type: 300ml/ 500ml (customized) 9.Filling working procedure: Put the bottle on the station→CO2 filling→beer filling→stop

10.Capping working procedure: Put the bottle on the station→capping→stop

Double head-CAN filling machine

1.Dimension=0.55x0.40x0.80m, gross weight=20kg

2.Filling capacity: 3-4PCS/MIN/STATION | total 2 Stations

3.Filling Speed:330ml-15s, 550ml - 20s 4.Power supply: Singel Phase 110V-240VAC 50/60Hz is default

5.Power consumption: 100w

6.Main Material is 304 Stainless steel

7.Beer Source Pressure:0.08-0.15MPa (12-22psi)

8.Co2 Pressure: 0.05-0.08MPa (9-12psi)

9.CO2 Regulator 20 psi from plant system connected to canning system with 3/8 OD barbed fitting

10.Installation source: CO2, Ice water (-2℃~ -1℃) 11.Can

11. Volume type: 330ml-568ml

ABOUT US

CUSTOMER FEEDBACK

CERTIFICATION

Layout: If you have conditions to send us your floor plan or sketch, or tell us the size (length, width, height) and the capacity and type of the fermentation equipment you want, we will provide you with the corresponding plan. Tailor-made for you

2. After-sales service:

The warranty period for core components is 1 year, and the tank body warranty is 3 years. Within one year, no one’s factor causes the electrical components to fail, we provide it for free or repair it for you. After the warranty, if you need to replace parts, we will wholeheartedly provide you with the most favorable price, when you encounter technical problems during use, we will wholeheartedly provide you with service

Похожие товары

Домашнее пивоваренное оборудование

US $760.00-$780.00

200L CIP система 2 сосуда 3 регулируемых CIP

US $1000-$8000

Ферментер/ферментер пилотного масштаба/биореактор/ферментация

US $7800-$10000