Single face corrugating machine / corrugated package

- Категория: Packaging Forming Machines >>>

- Поставщик: Cangzhou,Lighten,Import,&,Export,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 22015.51 $* | 23116.78 $* |

| Aug-18-2025 | 21830.60 $* | 22922.75 $* |

| Jul-18-2025 | 18315.79 $* | 19231.4 $* |

| Jun-18-2025 | 21460.46 $* | 22533.0 $* |

| May-18-2025 | 18685.68 $* | 19619.41 $* |

| Apr-18-2025 | 21090.32 $* | 22145.79 $* |

| Mar-18-2025 | 20905.66 $* | 21950.78 $* |

| Feb-18-2025 | 20720.52 $* | 21756.36 $* |

| Jan-18-2025 | 20535.67 $* | 21562.18 $* |

Характеристики

Product Description

SF-405E Multi-cassette positive pressure single facer/quick change roll single facer machine

1.using negative pressure design, lower heat consumption, helps the core paper to press evenly and close to the surface of corrugated roller, make the corrugate molding better, because the pressure evenly, the top of corrugate can glue uniform and better, make the single corrugated paper have perfect laminating.

2.quickly change rollers in 15 minutes, while change corrugated roller with the electric trolley loading,put into the machine,and air pressure system will lock it,fixed to the machine base,only need a few buttons can complete the replacement quickly and easily.

3.corrugated roller adopt50CRMO high quality alloy steel, dealing with heat,after grinding tungsten carbide surface treatment.

4.corrugated roller, pressure roller adopt airbag control system having high stability, having the barometric pressure control buffering effect at the same time.

5.Glue volume control with electric adjustment,rubber septum electric device,the glue system can operate independently when the motor stops,prevent glue exhausted。

6.the moveable type glue unit is convenient to clean and maintain。

7.easy operation control system, touch screen operation interface,Drawing with color display operating status, function selection, fault indication, and parameter settings, etc. can exclude exhibit this machine fully functional, easy to operate, user-friendly.

8.built-in pre-conditioner with proportional spraying device, adjustment the core paper temperature and moisture.

9.main, vice corrugating and pressure roller bearings are used in high-temperature grease to ensure bearing life running smoothly

2.quickly change rollers in 15 minutes, while change corrugated roller with the electric trolley loading,put into the machine,and air pressure system will lock it,fixed to the machine base,only need a few buttons can complete the replacement quickly and easily.

3.corrugated roller adopt50CRMO high quality alloy steel, dealing with heat,after grinding tungsten carbide surface treatment.

4.corrugated roller, pressure roller adopt airbag control system having high stability, having the barometric pressure control buffering effect at the same time.

5.Glue volume control with electric adjustment,rubber septum electric device,the glue system can operate independently when the motor stops,prevent glue exhausted。

6.the moveable type glue unit is convenient to clean and maintain。

7.easy operation control system, touch screen operation interface,Drawing with color display operating status, function selection, fault indication, and parameter settings, etc. can exclude exhibit this machine fully functional, easy to operate, user-friendly.

8.built-in pre-conditioner with proportional spraying device, adjustment the core paper temperature and moisture.

9.main, vice corrugating and pressure roller bearings are used in high-temperature grease to ensure bearing life running smoothly

quickly change rollers in 15 minutes, while change corrugated roller with the electric trolley loading,put into the machine,and air pressure system will lock it,fixed to the machine base,only need a few buttons can complete the replacement quickly and easily.

Product Paramenters

Design speed | 250m/min |

Economic speed | 200m/min |

Working width | 1000mm-2500mm |

Max working steam pressure: | 0.8-1.3Mpa |

Steam temperature | 160—200 centigrade |

Power requirements: | 380V, 50Hz |

Diameter of corrugated roller | Φ405mm |

Diameter of Press roller. | Φ495mm. |

Diameter of preheater roller | Φ420mm |

Diameter of Glue roller | Φ320mm |

Diameter of doctor roller | Φ175mm |

Name of main parts | Brands or place of origin |

Wallboard and base | Production by own |

Rotary joint and metal hose | Fujian quanzhou yujie |

Main frequency motor | Simens bade |

reducer | Taiwan CPG |

bearing | HRB,ZWZ,LYC or zhejiang wanxiang |

Seat belt bearing | Zhejiang wuhuan |

High pressure fan | Shanghai yingfa |

cylinder | Zhejiang sonor CSM |

Solenoid valve | Japan SMC or taiwan AirTAC |

traps | Beijing traps |

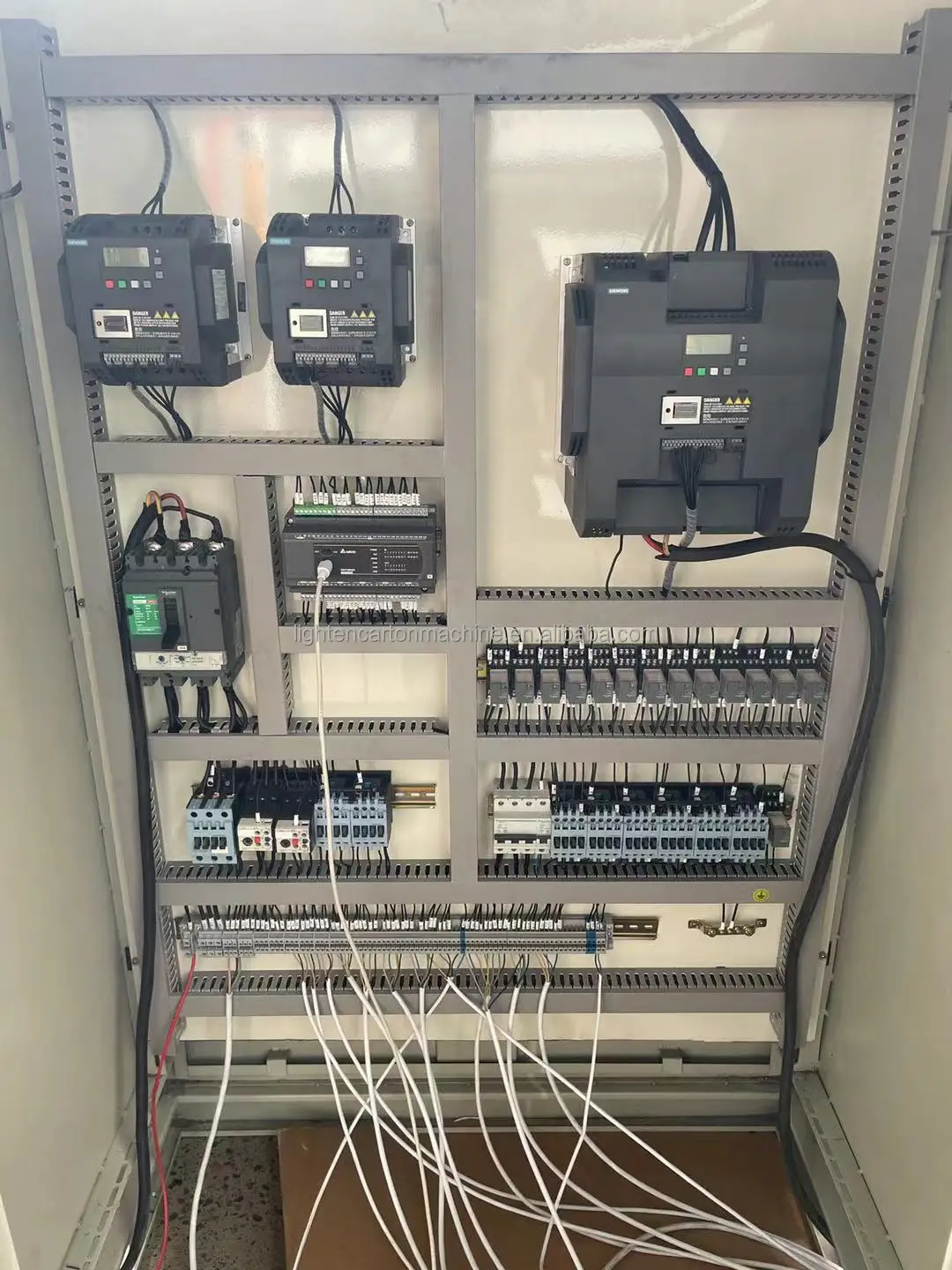

Contactors and Relays | France Schneider |

Position Sensor | Japan OMRON |

Frequency controller | simens |

PLC | simens |

Human machine interface | Beijing Kunlun-state |

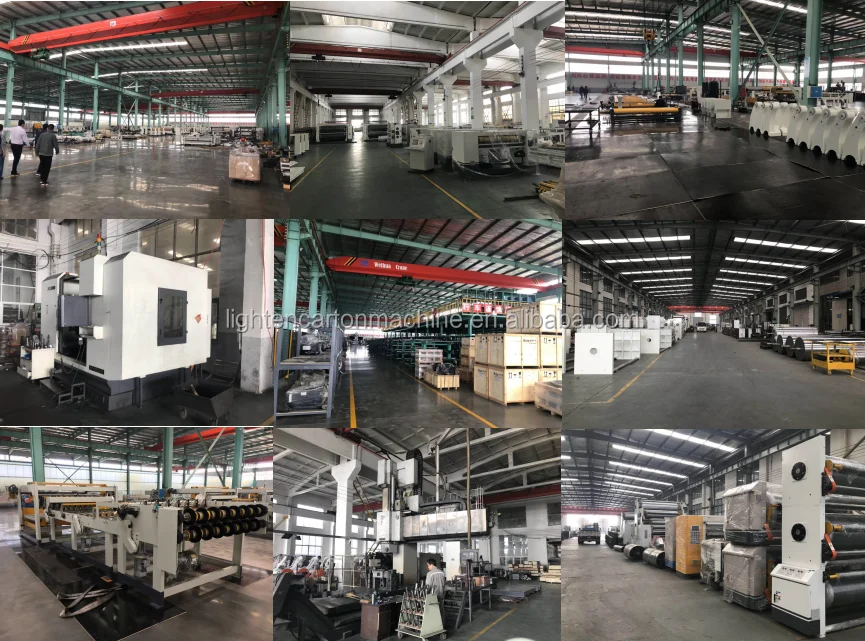

Company Profile

Product packaging

Other machines

FAQ

1. Q: Are you a factory or trading company?

A: We are a company owned our factory which is specialized in the production of various kind of carton equipment. (With export

license)

2. Q: How can I visit your factory?

A: We can pick you up if you need, welcome to visit our factory.

3. Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary

printing machine, creasing and die cutting machine,folder gluer,flute laminator,stitching&strapping machine and other corrugated

cardboard production equipments.

4. Q: How does your factory do regarding quality controlling?

A: Over the years our company take “the quality first” “integrity-based” corporate purpose always meet users’ requirements as our

sole purpose, providing the products with excellent quality, professional technology. Always attach great importance to quality

controlling from the very beginning to the very end.

1. All raw material we used are environmental-friendly.

2. Skillful workers care every detail in handling the producing and packing process.

3. Quality control department especially responsible for quality in each process.

5. Q: How is the evaluation of the products?

A: Products are distributed in Russia, the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country.

Product quality and enterprise reputation get the high praise at home and aboard.

6. Q: What is the payment term?

A: 30% deposit will be paid within 3 days after the contract is signed, and the remaining 70% will be paid before shipment.

A: We are a company owned our factory which is specialized in the production of various kind of carton equipment. (With export

license)

2. Q: How can I visit your factory?

A: We can pick you up if you need, welcome to visit our factory.

3. Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary

printing machine, creasing and die cutting machine,folder gluer,flute laminator,stitching&strapping machine and other corrugated

cardboard production equipments.

4. Q: How does your factory do regarding quality controlling?

A: Over the years our company take “the quality first” “integrity-based” corporate purpose always meet users’ requirements as our

sole purpose, providing the products with excellent quality, professional technology. Always attach great importance to quality

controlling from the very beginning to the very end.

1. All raw material we used are environmental-friendly.

2. Skillful workers care every detail in handling the producing and packing process.

3. Quality control department especially responsible for quality in each process.

5. Q: How is the evaluation of the products?

A: Products are distributed in Russia, the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country.

Product quality and enterprise reputation get the high praise at home and aboard.

6. Q: What is the payment term?

A: 30% deposit will be paid within 3 days after the contract is signed, and the remaining 70% will be paid before shipment.

Contact information

Похожие товары

Полностью автоматическая упаковочная машина для пластиковых пакетов

US $17000-$35000

Машина для резки образцов картонных коробок

US $22000-$30000