FYI новый дизайн дешевый текстильный роторный спиннинг с

- Категория: Spinning Machines >>>

- Поставщик: Hefei,Fanyuan,Instrument,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 14875.76 $* | 15619.86 $* |

| Aug-17-2025 | 14750.29 $* | 15488.24 $* |

| Jul-17-2025 | 12375.52 $* | 12994.24 $* |

| Jun-17-2025 | 14500.54 $* | 15225.87 $* |

| May-17-2025 | 12625.2 $* | 13256.2 $* |

| Apr-17-2025 | 14250.43 $* | 14963.85 $* |

| Mar-17-2025 | 14125.61 $* | 14831.2 $* |

| Feb-17-2025 | 14000.54 $* | 14700.58 $* |

| Jan-17-2025 | 13875.28 $* | 14569.47 $* |

Характеристики

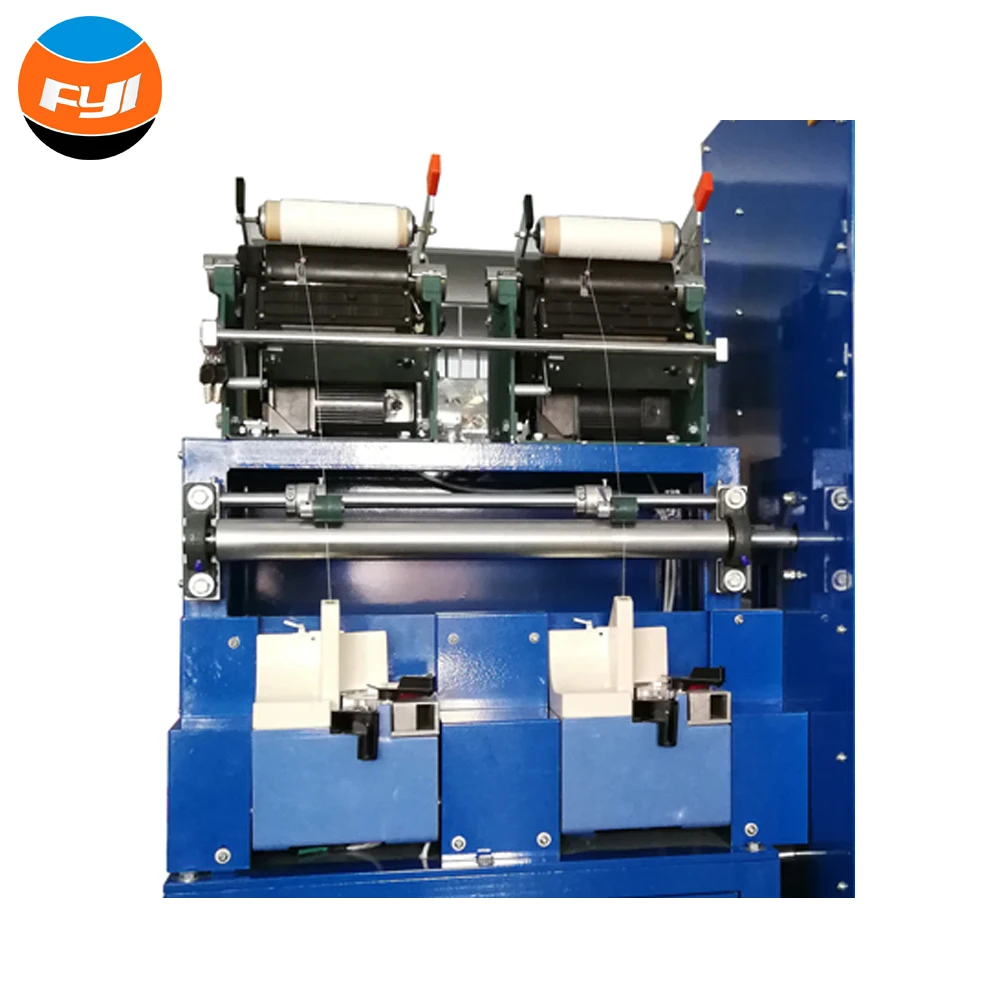

FYI New Design Cheap Open End Textile Rotor Spinning Machine

Application of Open End Spinning Machine:

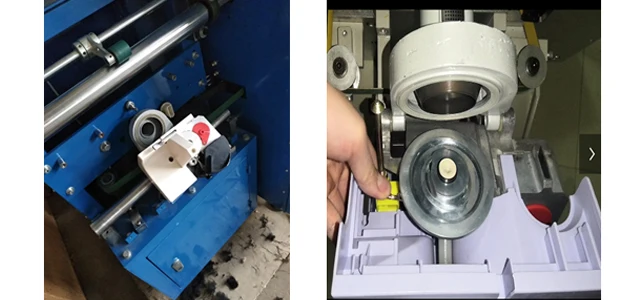

Open End Spinning Machine is used to produce open-end yarn by rotor spinning.This open end spinning machine can complete spinning yarn without using a spindle, ring or traveler and achieve faster speed, higher productivity and less cost than ring spinning. After the sliver is fed into the machine, it is opened by the carding roller, and then goes into the rotary cup. After twisting, the open-end yarn is formed and comes out, wrapped on a paper bobbin. There is no need for roving frame or cone winding machine.

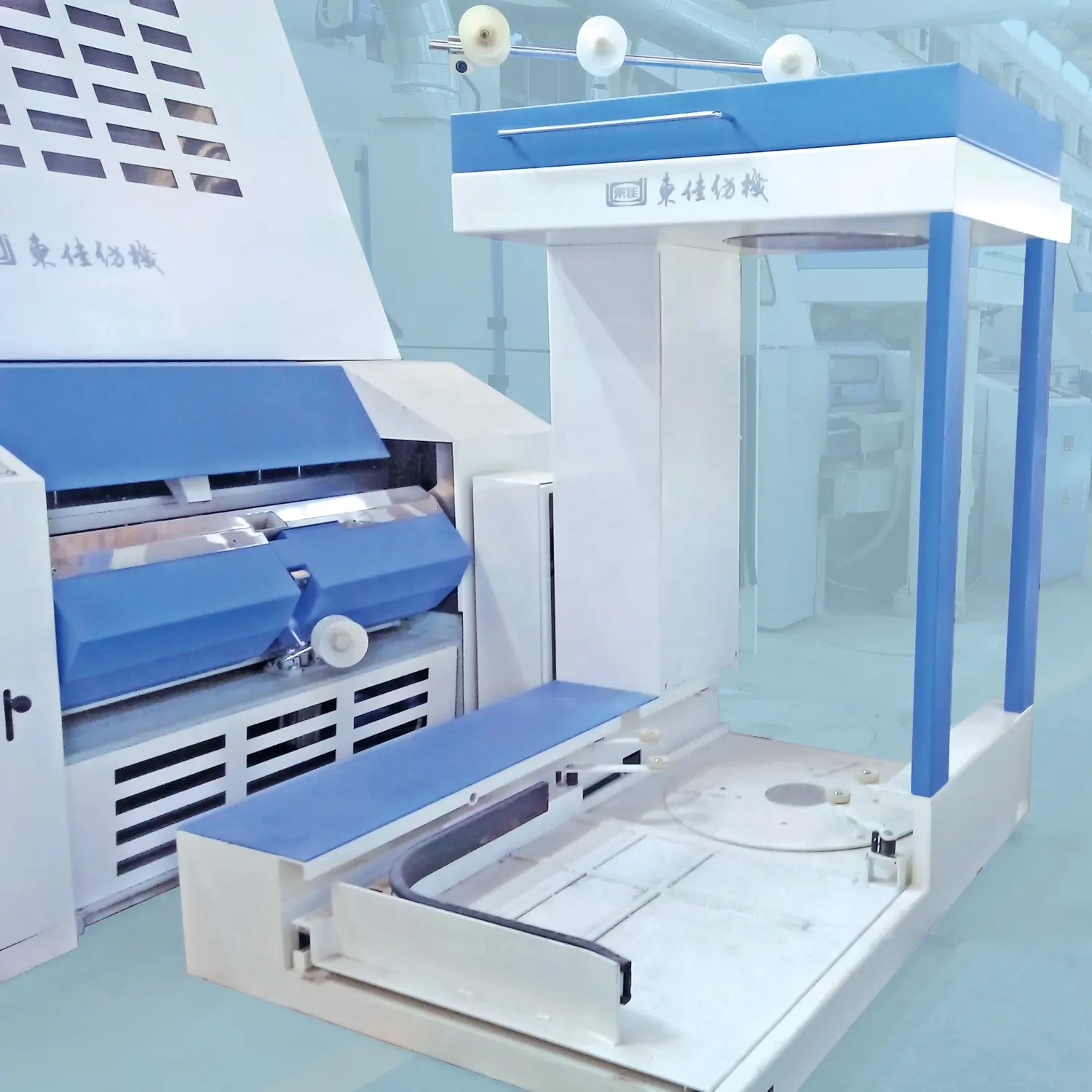

The rotor spinning machine has small dimension with PLC & touch screen control, simple to operate and adjust, so as to suitable for schools, research institutes and R&D centers.There have 1/2/4 spindle for optional .Customer can check the correct one before they order.

Key specification of Open End Spinning Machine:

fiber type and length | Cotton, 22~42mm |

Control mode | PLC & touch screen |

Number of rotor | Normal: 1 rotor, or as specified |

Rotor speed | 35,000RPM |

Carding roller speed | 6,000RPM |

Coiling speed | 20~110m/min |

Draft range | 30~250 |

Power supply | AC220V, 50Hz 1.2kW |

Package dimension | 1400×900×1800mm(L×W×H) for 2 rotors |

Net/Gross weight | 500/600kg for 2 rotors |

What material to use:

1. Large touch screen & PLC control and easy to use .

2. Use touch screen as man-machine interface, input technical parameters and show machine running state by touch screen;

3. Aluminum profile body frame ,free to move;

4. High speed rotor can meet with different customer enquiry .

5. Equipped with More spare parts

6. Multi-functional design, easy to clean, set and maintain;

7. Beautiful internal circuit

8. Unique structure easy to hang yarn

Installation in customer's lab Training in FYI showroom

Customer in our factory

Standard wooden packaging

Installation notes of open end spinning machine

Environment required to install the machine must meet requirements as below:

l Dry place, no drips, steam or oily dust;

l No corrosive, flammable gas or liquid;

l Solid base and no vibration;

l No electromagnetism and noise;

l To minimize electrostatic charge, it is much better if constant temperature & humidity room, 28°C;