Кислородная установка высокой очистки O2 медицинская для разлива

- Категория: >>>

- Поставщик: ALL,IN,ONE,MEDICAL,GROUP,CO.,LTD

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.44 $* | 0.31 $* |

| Aug-15-2025 | 0.76 $* | 0.53 $* |

| Jul-15-2025 | 0.19 $* | 0.79 $* |

| Jun-15-2025 | 0.52 $* | 0.74 $* |

| May-15-2025 | 0.70 $* | 0.9 $* |

| Apr-15-2025 | 0.31 $* | 0.29 $* |

| Mar-15-2025 | 0.19 $* | 0.66 $* |

| Feb-15-2025 | 0.92 $* | 0.32 $* |

| Jan-15-2025 | 0.83 $* | 0.14 $* |

Характеристики

Recommend Products

Product Paramenters

High Puriry O2 Oxygen Plant Medical Oxygen Producer Plant for Gas Filling Equipment

Item: | PSA Nitrogen/Oxygen Generator |

Control Mode: | automatic |

Gas Production: | 25Nm³/h |

Purity of Product Gas: | 93% |

Product Gas Dew Point: | ≤-30℃ |

Compressed Air Consumption: | 400/Nm3/h |

Intake Pressure: | 0.7-0.8Mpa |

Outlet Pressure: | 0.1-0.45Mpa(The user can adjust the exhaust pressure according to the actual needs) |

Rated Power: | Air compressor 37kW + cold dryer 1.5KW + oxygen generator 0.2Kw+ Oxygen booster 15KW |

PSA Oxygen Generation System: | Air Compressor 1 Set, Air Buffer Tank 1 PC, Freezing Dryer 1 Set, Precision Filter 3 PCS, Energy Saving PSA Oxygen Generator 1 Set, Oxygen Process Tank 1 PC |

Working Principle

PSA oxygen generator uses high-quality zeolite molecular sieve as adsorbent to produce oxygen from air under certain pressure according to the principle of pressure swing adsorption. The purified and dried compressed air is adsorbed under pressure and desorbed under reduced pressure in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much higher than that of oxygen. Nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen. Then, after decompression to atmospheric pressure, the adsorbent desorbs the adsorbed nitrogen and other impurities to realize regeneration. Generally, two adsorption towers are set in the system, one for adsorption and oxygen production, and the other for desorption and regeneration. The PLC program controller controls the opening and closing of the pneumatic valve to make the two towers circulate alternately, so as to achieve the purpose of continuous production of high-quality oxygen. The whole system consists of the following components: compressed air purification assembly, air storage tank, oxygen and nitrogen separation device and oxygen buffer tank; If steel cylinders need to be filled, oxygen booster and cylinder filling device shall be installed at the end.

Product Photos

Company Profile

Our Customers

Certifications

Packing & Delivery

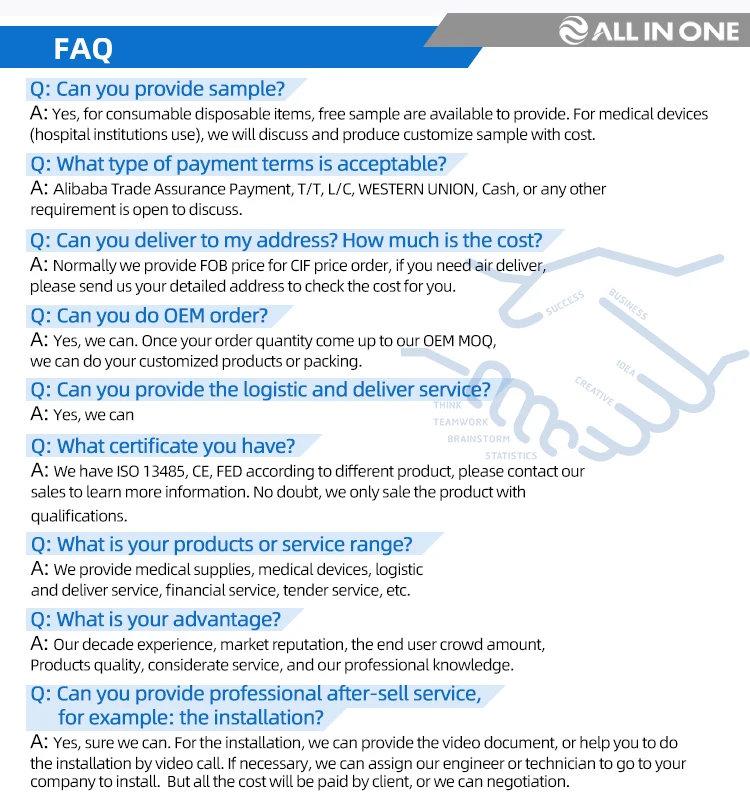

FAQ