Машина для резки толстых резиновых полос машина круглых мягких труб ПВХ

- Категория: Cloth Cutting Machines >>>

- Поставщик: Kunshan,Xuxin,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 712.12 $* | 748.4 $* |

| Aug-15-2025 | 706.78 $* | 741.47 $* |

| Jul-15-2025 | 592.0 $* | 622.58 $* |

| Jun-15-2025 | 694.64 $* | 729.22 $* |

| May-15-2025 | 604.61 $* | 634.50 $* |

| Apr-15-2025 | 682.52 $* | 716.40 $* |

| Mar-15-2025 | 676.73 $* | 710.61 $* |

| Feb-15-2025 | 670.83 $* | 704.70 $* |

| Jan-15-2025 | 664.31 $* | 697.68 $* |

Характеристики

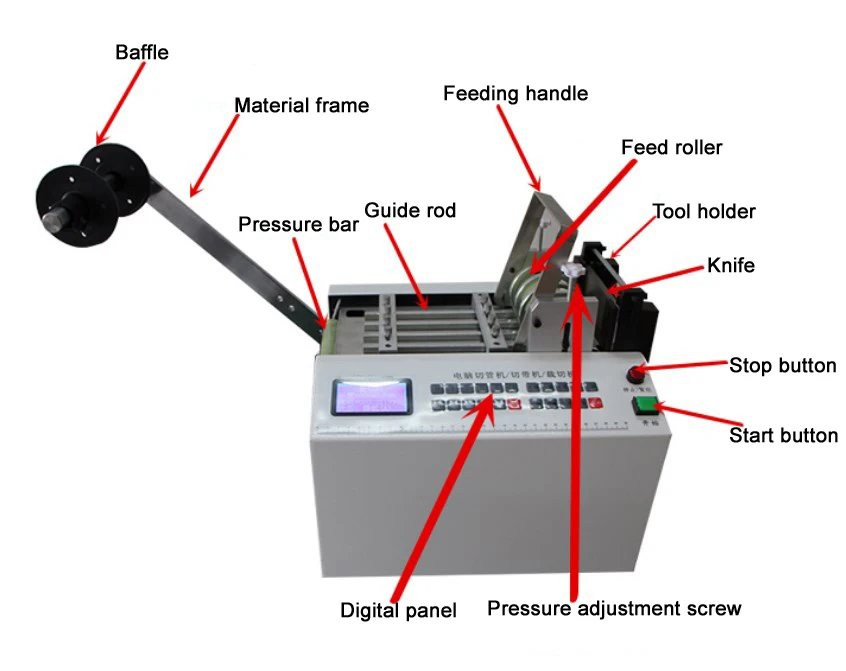

Automatic spread sheet slicing machine / nickel slicing machine X-100MC

Specifications:

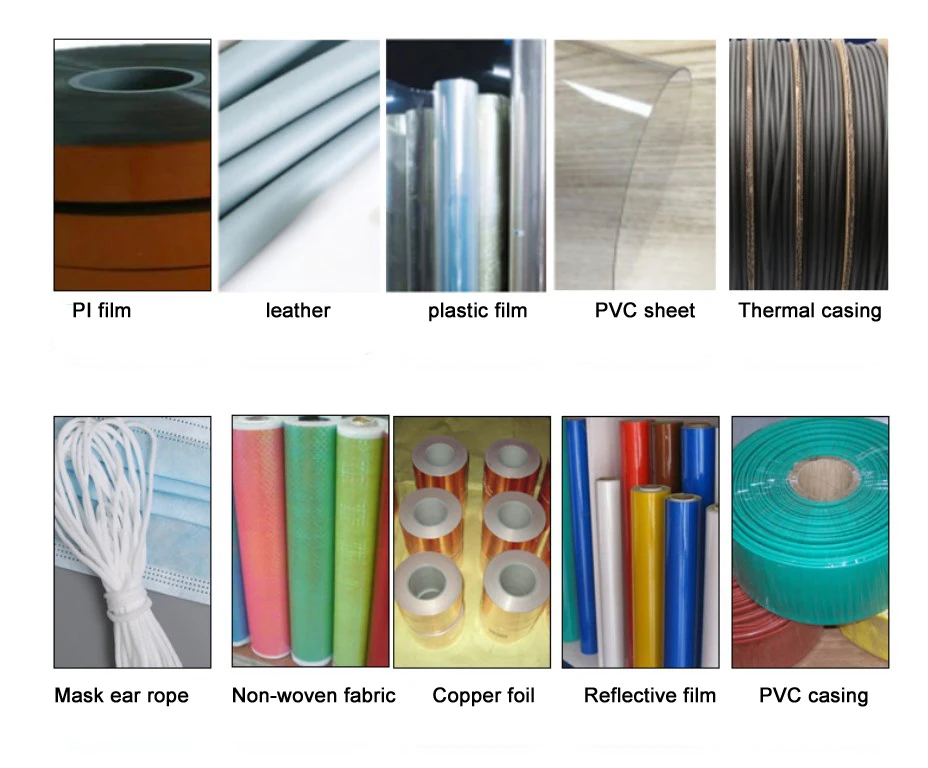

This computer automatic cutting machine is suitable for various industries. The products have been successfully cut as follows: heat shrinkable tubing, heat shrinkable film, electrolytic capacitor PVC tubing, PE plastic tape (bag), plastic film, insulating paper, wire, Various electronic wires, adhesive strips, sealing tapes, magnetic strips, silicone strips/tubes, rubber strips/tubes, silicone raw materials, double-sided tape, sealed bags, non-woven fabrics, Velcro, EVA, rubber pads, webbing, hook and loop tape , Safety belts, colored belts, plastic sponges, copper foil, aluminum foil, various adhesive tapes, flexible circuit boards, etc. for fixed-length cutting.

Parameters:

Model | X-100M | X-100MC |

Control mode: | computer pulse control | |

Knife material: | high-speed steel blade (thickness 8MM) | |

Cutting length: | 0.1 mm-100m (can be extended to 1000 meters if necessary) | |

Cutting width: | 0.1mm—100mm |

|

Cutting speed: | 120 times/minute | 150 times/minute |

The highest precision: | 0.1mm | |

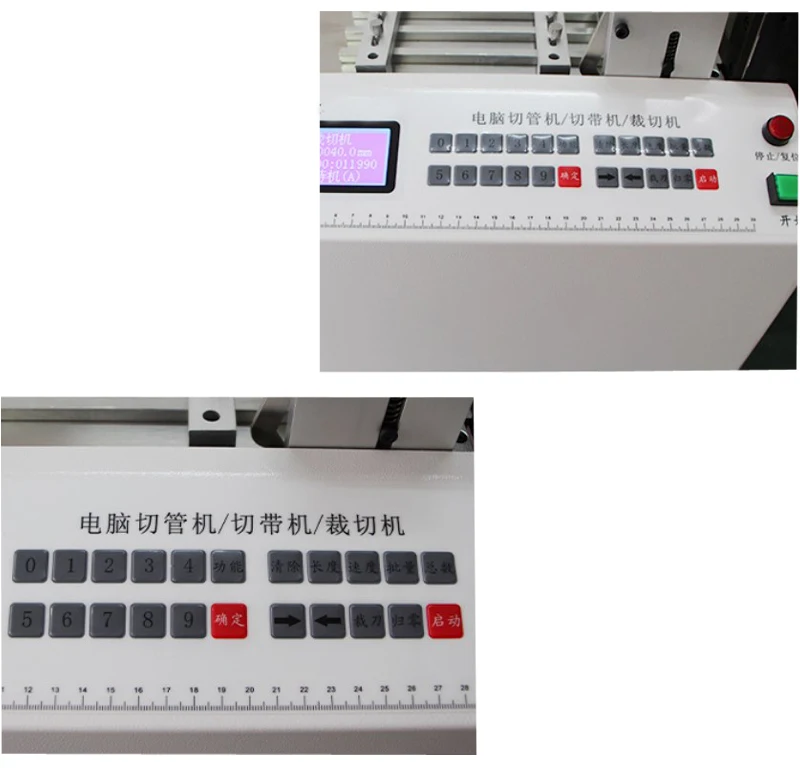

Display mode: | Chinese/English display on LCD | |

Input power: | 220V 50/60HZ | |

Cutter power:

| 95W | 400W |

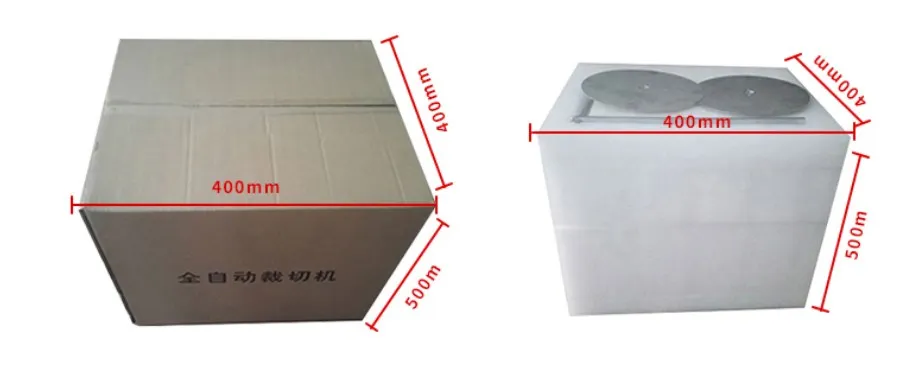

Dimensions: | L360*W250*H350mm | L360*W300*H350mm |

Volume and weight: | 26KG | 30KG |

Features:

1, High-speed feeding, controlled by a microcomputer program with an accuracy of 0.1MM

2, Adjustable cutting speed, full Chinese LCD display (Chinese interface, clear at a glance, English interface can be used for export or foreign companies)

3, Feeding length and speed can be adjusted continuously (pure numerical control adjustment, you only need to enter the number to adjust the length and speed and other parameters, no need to adjust the machinery and other parts)

4, With counting function, one side is cut and the other side is counted, and the work can be stopped automatically when the number is counted (set according to the order to reduce waste)

5, Batch pause and delay time can be set (set according to production speed to avoid material accumulation)

6, High-speed stepping motor accurately controls the cutting length

7, Cutter time protection; total number setting; splitting setting; splitting pause time adjustable;

8, Various manual operations are available for easy debugging;

9, LCD screen intuitive Chinese display, simple and convenient operation

10,The feeding motor and cutter motor are stepper motors imported from Panasonic, with original drivers.

11, Life span is 3-5 times longer than ordinary domestic motors;

12, The drive circuit chip adopts the Texas chip, which has good stability, high precision of the drive motor and long service life;

13, It can be equipped with an electronic eye detection instrument for tracking, positioning and cutting, while still retaining all the functions of the original machine, which is equivalent to a dual-purpose cutting machine;

14, Synchronous sensor can be installed to realize the synchronization of cutting machine and feeder.

Note: The advantages of high-power XX-160M over ordinary power XX-100M:

1. Double the power, the knife width is 60MM

2. The empty feeding speed is 3 times faster (60 m/min, ordinary type 20 m/min)

3. The feeding force is 3 times larger, and the cutter force is 5 times larger.

4. The maximum cutting length can be set to 100 meters (normally 10 meters).

5. There are two cutting machine modes: automatic and manual (ordinary equipment only has automatic mode of continuous cutting, and there is no manual mode of cutting one by one according to the needs of the production line).

6. The press block of the tool holder is thickened from 3mm to 30mm, and the spring of the tool holder is increased from 6 to 8; (the tool holder is more stable)

Application:

Our Advantages

* Best products and factory price.

* On-time delivery and the shortest delivery time.

* OEM and customized service.

* User manuals will go with relative machines.

* 1-year warranty.

If our products cannot function properly within 12 months, we'll offer spare parts for free; and you need to pay for the delivery.

Our Service

* QC: All products will be checked before delivery.

* Compensation: If any unqualified product is found, we'll pay the compensation or send new qualified products to customers.

* Maintenance & Repair: In case of any maintenance or repair need, we'll help to find out the problem and offer relative guidance.

* Operation Guidance: If you have any problem with operation, please feel free to contact us.