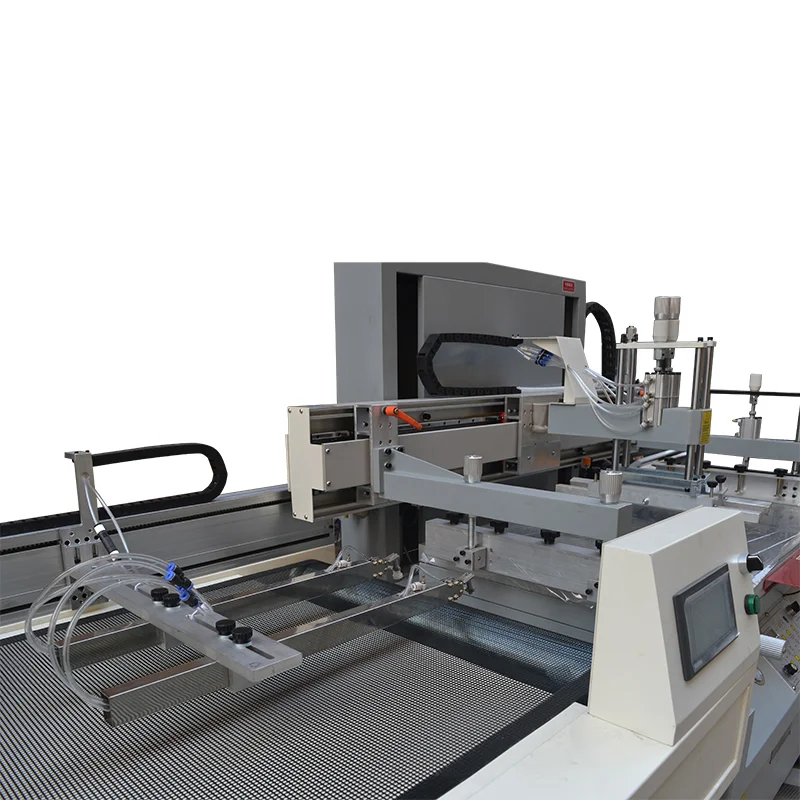

TAOXING Горячая продажа автоматическая трафаретная печатная машина с манипулятором и

- Категория: Screen Printers >>>

- Поставщик: Hangzhou,Taoxing,Printing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.52 $* | 0.8 $* |

| Aug-15-2025 | 0.66 $* | 0.78 $* |

| Jul-15-2025 | 0.59 $* | 0.20 $* |

| Jun-15-2025 | 0.99 $* | 0.10 $* |

| May-15-2025 | 0.88 $* | 0.75 $* |

| Apr-15-2025 | 0.63 $* | 0.38 $* |

| Mar-15-2025 | 0.34 $* | 0.6 $* |

| Feb-15-2025 | 0.32 $* | 0.12 $* |

| Jan-15-2025 | 0.94 $* | 0.88 $* |

Характеристики

Specifications

Application:

It is suitable for the plane printing of glass, optical disc, nameplate, adhesive, credit card, ceramic paper, wooden toy puzzle,PCB, SMT solder paste, film switch and other products in electronic industry, as well as for the plane printing of products with high overprinting accuracy based on gold and silver cardboard, metal sheet, PVC and so on.

Features:

① Vertical structure, frequency conversion electric drive is used for vertical lifting of screen plate, and frequency conversion electric drive is used for left and right action of printing head.

② Single chip microcomputer control circuit, printing and screen lifting using independent drive source.

③ Pneumatic control printing tool carrier lifting, photoelectric eye control stroke, independent adjustment.

④ Set up manual/semi-automatic/automatic three modes, printing indirect time digital control.

⑤Independently designed head lifting device, scraper/return knife, screen loading and unloading and screen cleaning is convenient.

⑥ Double guide post left and right net clip arm, and installation of plate distance adjustment device, easy to adjust.

⑥ Double guide post left and right net clip arm, and installation of plate distance adjustment device, easy to adjust.

⑦With a thimble cylinder, with the manipulator to take material.

①Equipped with 2 sets of UV light source system, according to the production needs to open the number of lamps. ②Imported Teflon conveyor belt, Seiko production, smooth operation without noise

③Speed regulating motor and governor, conveyor belt stepless speed regulation, according to the production of speed regulation.

④Concentrating type design, imported high focusing reflective lampshade, instantaneous drying, speed is express.

⑤The illumination height of UV lampshade can be adjusted.

⑥The working current of the UV lamp tube can be displayed through the external indicator needle to effectively grasp the working state of the UV system.

⑦The heat can be discharged outdoors through the exhaust heat system, which effectively protects the production and

working environment.

working environment.

Manipulator:

①PLC control each function operation, simple and convenient operation

②Stepper motor with linear guide rail, fast and stable

③Machine structure is made of high quality aluminum alloy, light and strong;

Parameters:

Model | TX-5080ST |

Max printing area | 500*800CM |

Table size | 600*900CM |

Max mesh frame | 800*1200CM |

Max printing speed | 1000(PCS/H) |

Printing Thickness | ≤30mm |

Printing pressure | 4.0~6.0 kfg/c㎡ |

Voltage/power | 380V/50HZ /3.2KW |

Dimension | 1460*1150*1650CM |

Gross weight | 522(KG) |

Model | TX-UV600(800) |

Power/optical power | 380V/3KW*2PCS LAMPS(5.6kw,LAMP) |

Mesh belt width | 600mm(800mm) |

Input speed | 5-25m/min |

Manipulator length | 1.8M |

Weight | 325kg |

Machine length | 4M |

Machine Description

Recommend Products

Buyer Comment

Company Profile

Certification

Packing&Delivery

FAQ

Q: Are you a factory or trading company?

A: We are a professional manufacturing factory specialize in printing equipment with more than 20 years experience, committed to supplying our customer top quality and dedication to the constant improvements of quality,reliability, productivity and the competitiveness of our products and services.

Q: How to get a quotation?

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color,thickness, quantity, etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the machine depends on

your requirements.

Q: What are your terms of payment?

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

Q: How long is the warranty time?

A: All products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.

Q: How to get a quotation?

A: Please send us an inquiry directly. We need to get specific details, such as material, size, color,thickness, quantity, etc.

Q: Can you do the production as customized?

A: Yes, we have a professional technique team, we could produce the machine depends on

your requirements.

Q: What are your terms of payment?

A: We accept TT/LC/PAYPAL/Western union, every payment term we can discuss.

Q: How long is the warranty time?

A: All products carry up to a full year warranty. Supply wearing parts with favorable price and long term after-sales service. We believe in total customer satisfaction, aside from our no-hassle guarantee.