Luoyang hongteng Электрический 8-32 мм стальной арматуры горячей прокатки мельница tmt стержень сделать машину угол

- Категория: Rolling Mill >>>

- Поставщик: Luo,Yang,Hongteng,Electrical,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 119000.80 $* | 124950.36 $* |

| Aug-17-2025 | 118000.65 $* | 123900.6 $* |

| Jul-17-2025 | 99000.36 $* | 103950.91 $* |

| Jun-17-2025 | 116000.41 $* | 121800.56 $* |

| May-17-2025 | 101000.27 $* | 106050.59 $* |

| Apr-17-2025 | 114000.85 $* | 119700.71 $* |

| Mar-17-2025 | 113000.38 $* | 118650.3 $* |

| Feb-17-2025 | 112000.22 $* | 117600.22 $* |

| Jan-17-2025 | 111000.84 $* | 116550.7 $* |

Характеристики

Luoyang hongteng electrical 8-32mm steel rebar hot rolling mill tmt steel bar make machine angle steel hot rolling mill

Product Description

Hot rolling mill is mainly used in iron and steel plants to produce special-shaped bars, wires, channel steel, flat bars, steel plates and other products.

1. Hot rolling mill is mainly used in iron and steel plants to produce steel bar, special-shaped bars, wires, channel steel, flat bars, steel plates and other products. The raw material is steel scrap or billet (40-100mm).

2. The small production capacity of 0.5- 5t/h is the standard product of our company.

3. The diameter of the steel bar of the final product: 8-32mm, the length: 3000-12000mm.

1. Hot rolling mill is mainly used in iron and steel plants to produce steel bar, special-shaped bars, wires, channel steel, flat bars, steel plates and other products. The raw material is steel scrap or billet (40-100mm).

2. The small production capacity of 0.5- 5t/h is the standard product of our company.

3. The diameter of the steel bar of the final product: 8-32mm, the length: 3000-12000mm.

1. What is steel rebar making machine rolling mill?

-- The steel rebar production line is the process that firstly pour the liquid steel into continuous casting machine to cast steel billets, and then without cooling and hold the steel billets in the soaking pit after a certain time directly into the continuous hot rolling mills to roll various formed steel rebars.

2. What is the advantage of steel rebar making machine rolling mill?

-- The process of continuous casting direct rolling mill is skillfully combine both casting and rolling processes, compared with the traditional process that first casting billets and heating again by heating furnace then rolling is simplified, improve working conditions, increase the metal yield, to save energy, improve the quality of continuous casting billet, easy to realize mechanization and automation.

3. What we can supply you?

a) We supply turnkey project of hot rolling mill plant for customers.

b) We will carefully confirm with customer's requirement first, design machines under customer's workshop size. Design drawing for customers to check.

c) Steel rebar production line can also produce deformed rebars, coiled bars, angle bars, flat bars, square bars, H bars etc.

d) We can supply steel rebar production line production capacity from 1T to 20T per hour. Most customers use waste iron melting to start. Some customers use steel billets to produce rebars.

e) Steel rebar production line have different standard automation for different customer's requirement.

-- The steel rebar production line is the process that firstly pour the liquid steel into continuous casting machine to cast steel billets, and then without cooling and hold the steel billets in the soaking pit after a certain time directly into the continuous hot rolling mills to roll various formed steel rebars.

2. What is the advantage of steel rebar making machine rolling mill?

-- The process of continuous casting direct rolling mill is skillfully combine both casting and rolling processes, compared with the traditional process that first casting billets and heating again by heating furnace then rolling is simplified, improve working conditions, increase the metal yield, to save energy, improve the quality of continuous casting billet, easy to realize mechanization and automation.

3. What we can supply you?

a) We supply turnkey project of hot rolling mill plant for customers.

b) We will carefully confirm with customer's requirement first, design machines under customer's workshop size. Design drawing for customers to check.

c) Steel rebar production line can also produce deformed rebars, coiled bars, angle bars, flat bars, square bars, H bars etc.

d) We can supply steel rebar production line production capacity from 1T to 20T per hour. Most customers use waste iron melting to start. Some customers use steel billets to produce rebars.

e) Steel rebar production line have different standard automation for different customer's requirement.

Customer site

Hot rolling production lines for deformed bars are divided into H Series small rolling mill and continuous rolling. The rolling type of continuous rolling is double groove and single line. It can reduce furnace scaling caused by secondary heating and improve the finished product rate by 0.3 ~ 0.5%.

Product Advantages

1, Provide overall solution and after-sales guarantee

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

Specification and Technical Parameter | ||||||||

Model | Power | Rolling Speed | Feeding Section | Rolling Specification | ||||

H220-2 | 95KW | 1.5-2 | 40*40mm | Φ10-24mm | ||||

H250-3 | 180kw | 1.8-2.5 | 50*50mm | Φ8-32mm | ||||

H250-4 | 315kw | 2.5-4 | 60*60mm | Φ8-32mm | ||||

Recommend Products

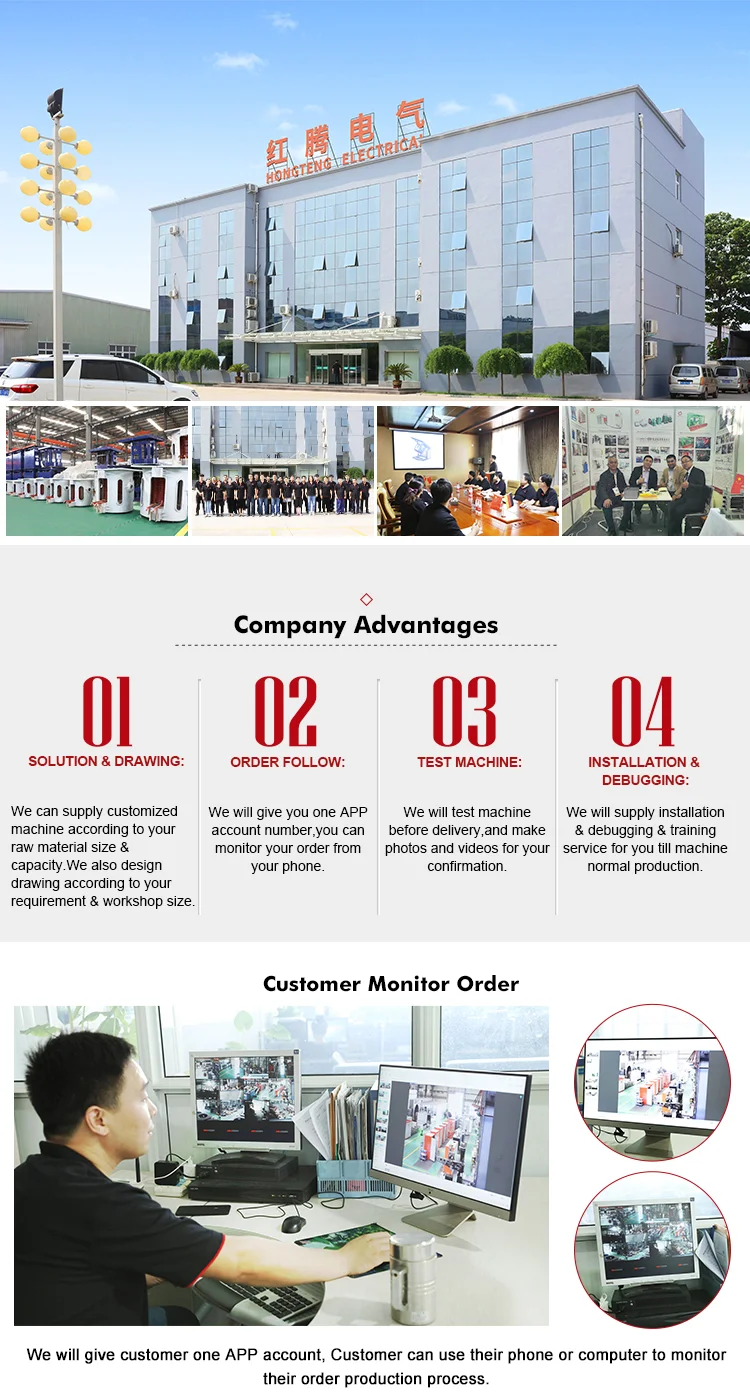

Why Choose Us

Certifications

FAQ

1: Are you the Manufacturer or a trading company?

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity, natural gas and LPG

4: How can I trust your company and machine?

Our factory have been in producing machinery for around 15 years ,our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as

Vietnam, Indonesia, Myanmar, Qatar, Ukraine etc. Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training service for customers till machine normal production.

We are direct manufacturer specialized in produce in machinery for 15 years.Our factory located in high industry zone,Luoyang city,henan province,where is the biggest industry machinery manufacturing base in china.

2: Why should we choose Hongteng?How do you ensure the quality?

We have professional research staff and strict in Production,inspection and debugging and package process.We always insist on supply good pre-sales,order following,after sell service for our customers.

We have professional QC person inspect machinery production.After production finished,all machines will be testing & debugging carefully before shipment.

3: Which kind of power supply do you supply? Electricity or gas?

Electricity, natural gas and LPG

4: How can I trust your company and machine?

Our factory have been in producing machinery for around 15 years ,our machine have exported to East Asia, South Asia, the middle East Asia, Africa etc. areas and have a good feedback with no complaints.

Welcome to visit us,and have a face to face negotiation.

5: How do you control the quality?

We have QC team comply with TQM to ensure the quality. Each step is in compliance to the standards. At the same time, we will take photos and shoot video for you if you need.

6: Which county do you exported to ?

We have already exported our machines to many famous company in many countries, such as

Vietnam, Indonesia, Myanmar, Qatar, Ukraine etc. Welcome customers to visit our factory.

7: How about your after sales service?

After customers get machines,We will send our engineers to customer's workshop.We will supply installation & debugging & training service for customers till machine normal production.