Небольшая вращающаяся барабанная сушилка для кокосовых семян зерна

- Категория: Drum Drying Equipment >>>

- Поставщик: Jiangsu,Shengman,Drying,Equipment,Engineering,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 35700.65 $* | 37485.47 $* |

| Aug-16-2025 | 35400.94 $* | 37170.16 $* |

| Jul-16-2025 | 29700.56 $* | 31185.42 $* |

| Jun-16-2025 | 34800.32 $* | 36540.71 $* |

| May-16-2025 | 30300.75 $* | 31815.15 $* |

| Apr-16-2025 | 34200.7 $* | 35910.79 $* |

| Mar-16-2025 | 33900.26 $* | 35595.67 $* |

| Feb-16-2025 | 33600.93 $* | 35280.88 $* |

| Jan-16-2025 | 33300.50 $* | 34965.83 $* |

Характеристики

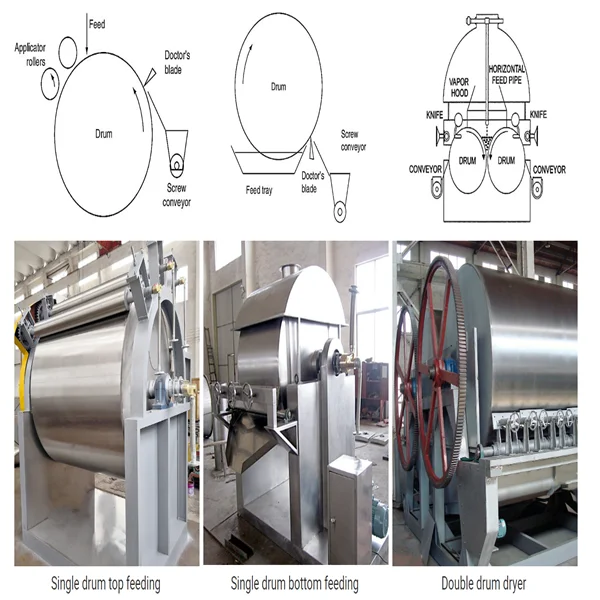

Working principle

HG series rotary drum dryer flaker is a continuous indirect heating drying processor. The dryer body consists of rotary drum heated by steam, applicator rollers, scrapper and exhaust hood. Liquid raw meterials are fed onto the rotary drum from the top. With the kneading effect of applicator system, raw materials are evenly spread onto the heated surface of rotary drum. Moisture evaporates very quickly. Drying process is done within a single rotation of the drum and the dried product is scrapped off with the knife.

HG series rotary drum dryer flaker with its continuous indirect drying method, allows short heat retention time while evaporating all the liquid within a single rotation of the drum. It not only virtually eliminates the risk of damaging the product but also enables the product to keep its unique properties like taste, smell, texture etc. Drum dryer is unique for drying viscous, pasty and sticky materials in food, chemical and pharmaceutical industries.

Technical parameters

| size | size of cylinder(mm) | heating area (m2) | drying capacity(kg/h) | power kw | weight |

| HG-600 | 600*800 | 1.12 | 40-70 | 1.1 | 850 |

| HG-700 | 700*1000 | 1.65 | 60-90 | 2.05 | 1210 |

HG-800 | 800*1200 | 2.26 | 90-130 | 3.75 | 1700 |

| HG-1000 | 1000*1400 | 3.30 | 130-190 | 4.75 | 2100 |

| HG-1200 | 1200*1500 | 4.24 | 160-250 | 4.75 | 2650 |

| HG-1400 | 1400*1600 | 5.28 | 210-310 | 6.25 | 3220 |

| HG-1600 | 1600*1800 | 6.79 | 270-400 | 6.25 | 4350 |

| HG-1800 | 1800*2000 | 8.48 | 330-500 | 8.6 | 5100 |

| HG-1800A | 1800*2000 | 10.6 | 420-630 | 8.6 | 6150 |

Features

1) High heat efficiency: Heat loss is mainly caused thermal radiation. Heat efficiency can be as high as 90%.

2) Short drying time: The drying process only takes 10-15 seconds. So drum dryer can be used for drying heat sensitive material.

3) Uniform drying: Heat transfer direction and coefficient all over the drum surface are the same. And wet material can be evenly spread over the drum surface. Wet material can be uniformly dried.

4) Long life span: Rotary drum is electro-polished and well heat treated to increase the smoothness and hardness.

5) Flexible application: Drum surface temperature, rotating speed, wet material film thickness are all adjustable to satisfy materials with different moisture and drying time.

6) Compact size: The drying chamber is very compact in size. Only need small installation space.

7) Low operation cost: The whole machine is very simple and reliable. It can be used for many years with little repair and maintenance.

8) Highest hygienic standard: Indirect heating and electro-polished drum surface can assure highest hygienic working conditions.

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost.