Skim покрытие миксер продукт сухой Раствор Завод керамическая плитка клей раствор производственная

- Категория: Dry Mortar Machines >>>

- Поставщик: Zhengzhou,Yishang,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 31892.17 $* | 33487.18 $* |

| Aug-19-2025 | 31624.96 $* | 33205.47 $* |

| Jul-19-2025 | 26532.54 $* | 27859.1 $* |

| Jun-19-2025 | 31088.57 $* | 32642.25 $* |

| May-19-2025 | 27068.89 $* | 28421.37 $* |

| Apr-19-2025 | 30552.23 $* | 32080.24 $* |

| Mar-19-2025 | 30284.73 $* | 31798.36 $* |

| Feb-19-2025 | 30016.10 $* | 31517.87 $* |

| Jan-19-2025 | 29748.95 $* | 31235.68 $* |

Характеристики

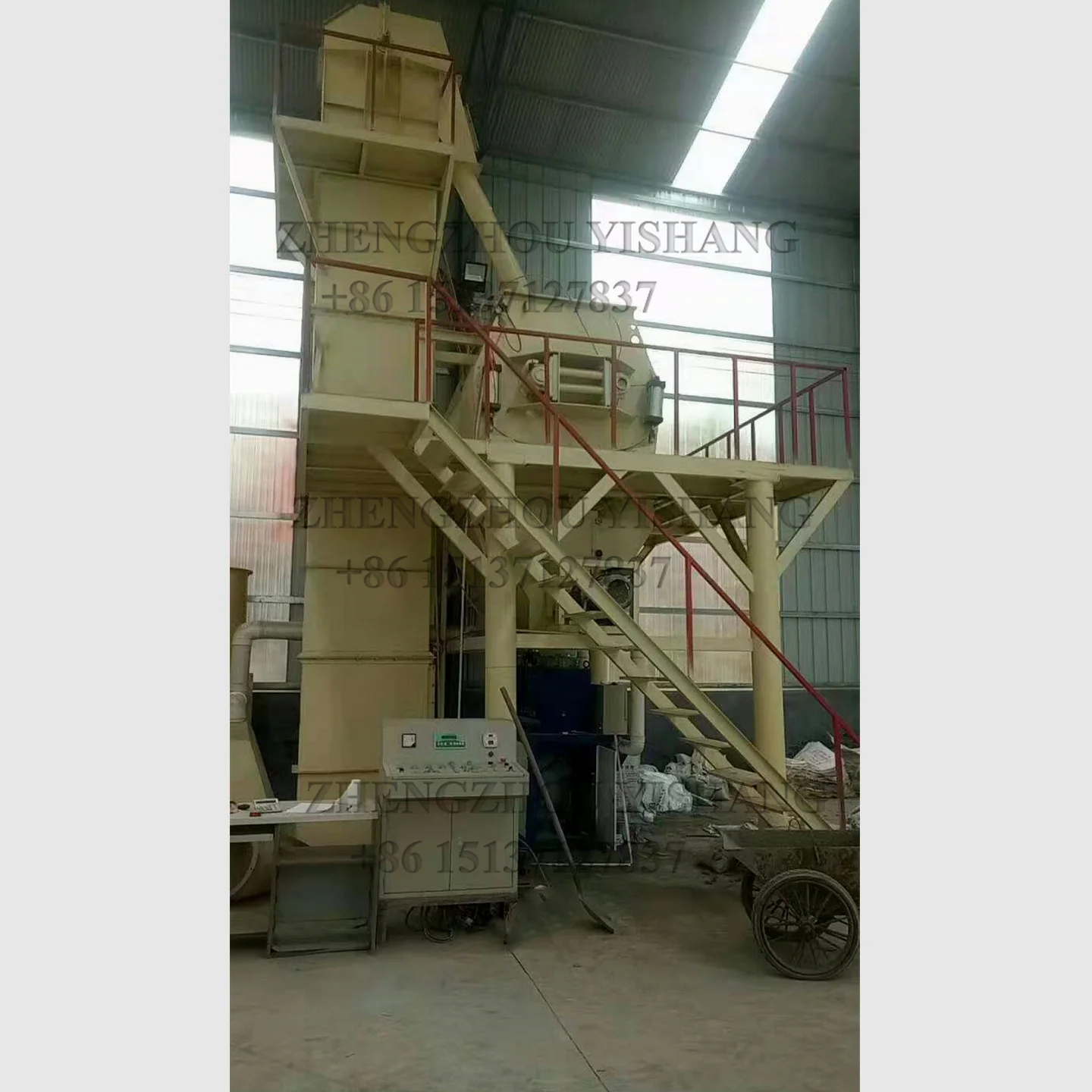

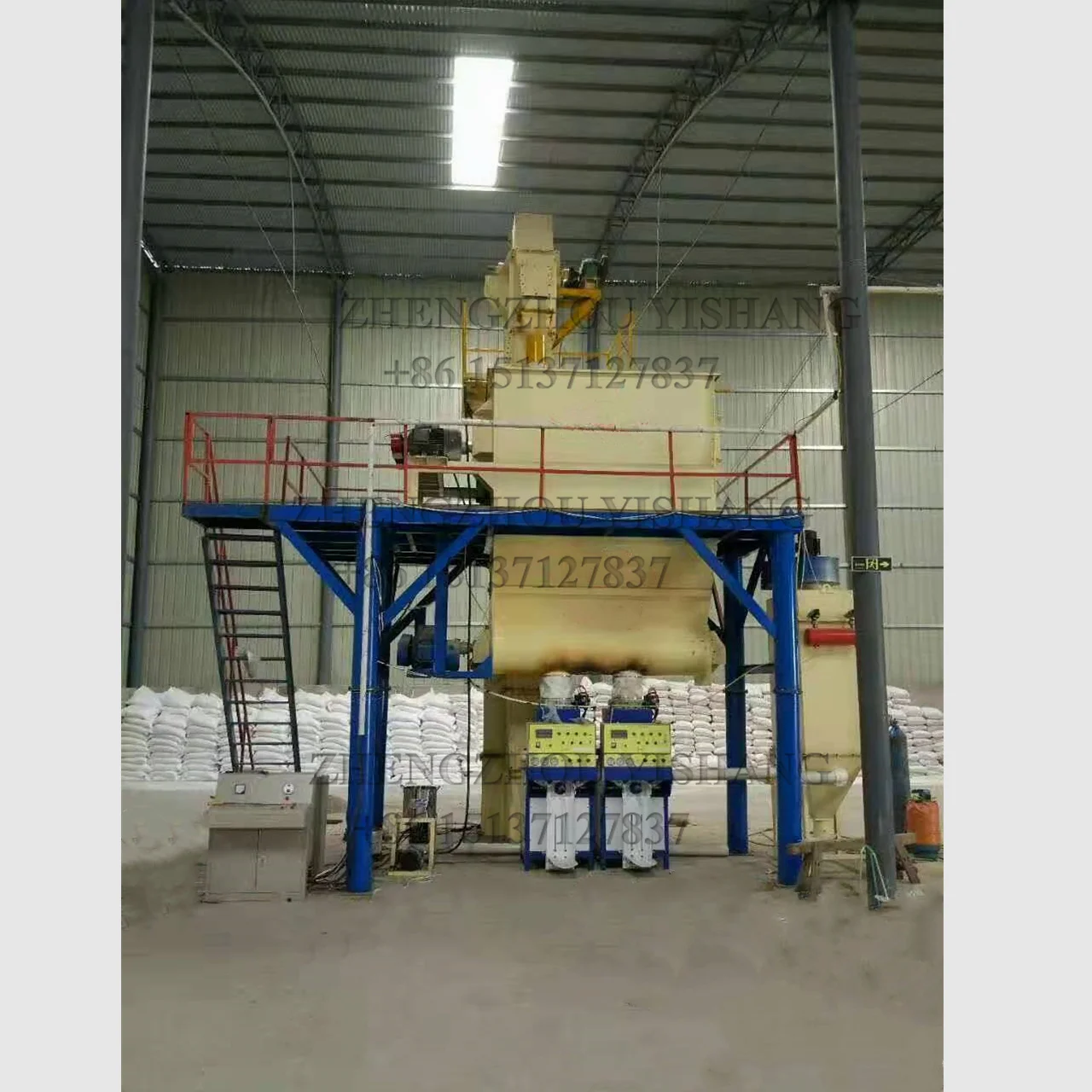

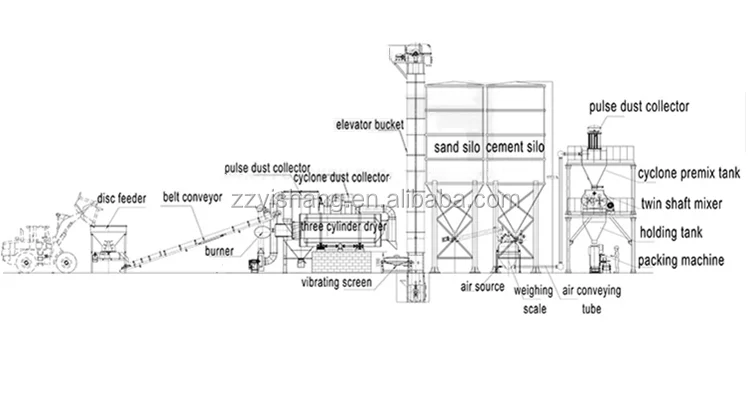

Skim coating mixer product dry mortar plant ceramic tile adhesive dry mortar production line

YS Full automatic dry mortar production line includes ready-mixed mortar equipment, building mortar equipment, tandem mortar equipment, station type mortar equipment. Including the storage of raw materials, drying, grading, metering, mixing, packing and bulk mechanical.Control full automatic operation by computer,Depending on the configuration, capacity at 10-35T/H, with an annual output of 30-100,000 tons per year. Occupation area: 60-100m² , Height: 8-13 m, Worker required: 3-5 person

YS Full automatic dry mortar production line includes ready-mixed mortar equipment, building mortar equipment, tandem mortar equipment, station type mortar equipment. Including the storage of raw materials, drying, grading, metering, mixing, packing and bulk mechanical.Control full automatic operation by computer,Depending on the configuration, capacity at 10-35T/H, with an annual output of 30-100,000 tons per year. Occupation area: 60-100m² , Height: 8-13 m, Worker required: 3-5 person

For example,the basic configuration of 10-15T/H automatic dry mix mortar production line

Name | Model | Power(kw) | Qty. |

Raw Material Storage System | 60T Detachable Silo | -- | 3units |

Mixing System | Twin Shaft Paddle Mixer DWZ-2000 | 18.5kw | 1unit |

Pre-Mix Hopper 2m2 | -- | 1unit | |

End Product Hopper 2m2 | 5.5kw | 1unit | |

Conveying System | Screw Conveyor LSY219 | 7.5kw | 3units |

Indoor Bucket Elevator TD38/25 | 4kw | 1unit | |

Chain Hoist NE15 | 4kw | 1unit | |

Batching System | Batching Hopper 2m2 | 5.5kw | 1unit |

Packing System | Valve Packing Machine | 3kw | 1unit |

Control System | PLC Control & Cabinet |

| 1unit |

Dedust System | Pulse Dust Collector DMC15 | 3kw | 1unit |

Bag Dust Collector for Packing Machine | 3kw | 1unit | |

Air Supply System | Air Compressor V-0.6/8 | 5.5kw | 1unit |

Steel Structure | Layer -2 Steel Platform |

| 1unit |

Material tank |  |

| YS Double shaft paddle mixer |

PLC electric control system 1. Efficient and accurate control system |  |

| Automatic weighing system 1. Equipped with advanced weighing system, with accurate, stable, reliable and other characteristics. 2. According to the raw material formula, automatic weighing, high precision, reduce the weighing error 3. Save labor costs and increase production. |

(1)FCL: export equipment standard container

(2) wooden box: The size of the packing box shall be designed according to the equipment

The widget is attached to the machine

Soft wood is placed in front or back of the machine to protect it.

The plastic film is covered in this machine for waterproofing

The equipment into the container with the crane