PS пенопластовый одноразовый пластиковый контейнер для еды/машина производства

- Категория: Plastic Vacuum Forming Machines >>>

- Поставщик: Longkou,Tongyi,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 119000.91 $* | 124950.84 $* |

| Aug-18-2025 | 118000.6 $* | 123900.39 $* |

| Jul-18-2025 | 99000.31 $* | 103950.23 $* |

| Jun-18-2025 | 116000.76 $* | 121800.42 $* |

| May-18-2025 | 101000.84 $* | 106050.85 $* |

| Apr-18-2025 | 114000.50 $* | 119700.42 $* |

| Mar-18-2025 | 113000.6 $* | 118650.90 $* |

| Feb-18-2025 | 112000.85 $* | 117600.26 $* |

| Jan-18-2025 | 111000.71 $* | 116550.97 $* |

Характеристики

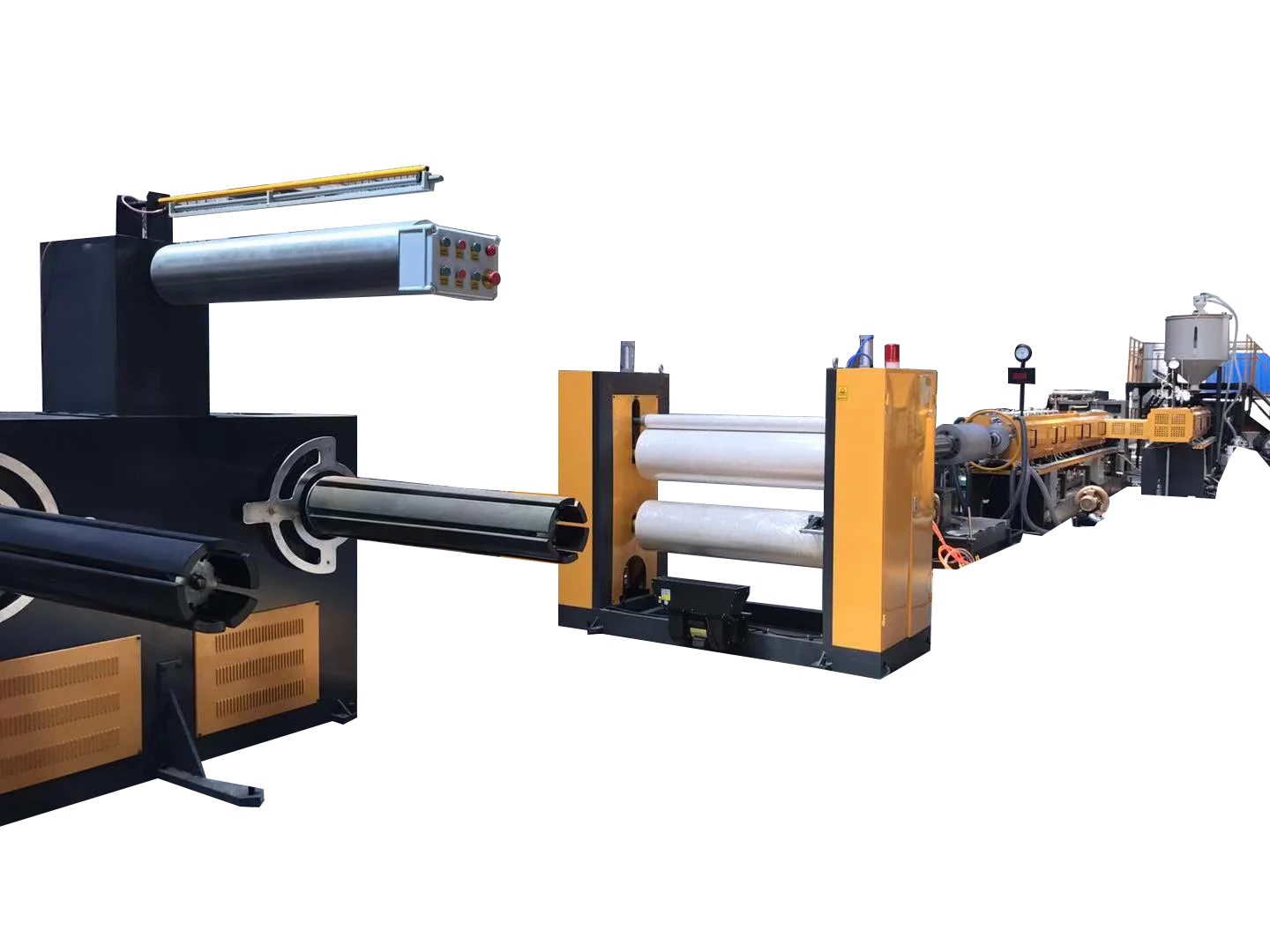

Ps Foam Disposable Take Away Plastic Food Lunch Box/Plate Making Machine

We specialize in manufacturing the following products: Plastic Foaming Machinery, Packing Machinery, Pulp Moulding Machinery with about 31 years experiences. Our enterprise management concept is based on innovation, excellent quality and skilled workmanship. So we are enjoying a good reputation through over 100 countries and areas and have got customers' trust deeply.

Moreover, our sales volume of foaming machinery is No. 1 compared with other Chinese suppliers. We sincerely hope to cooperate with friends from home and abroad and help you succeed with our profession.

|

PS food container machine mainly including three main parts:

1. PS foam sheet extruder: make PS foam sheet from raw material

2. Fully auto forming and cutting machine: make PS sheet to finished products, such as PS foam tray, PS foam box etc (we can design mould according to customer requirements)

3. Plastic recycle machine: recycle waste products to granules, the can mix with new material and put into PS foam sheet extruder again |

Main technical parameters

Model | Unit | PSP75/99 | PSP105/120 | PSP120/130 | PSP135/150 | PSP180/200 |

Extruder |

| 75/99 | 105/120 | 120/130 | 135/150 | 180/200 |

Foam rate |

| 10-20 | 10-20 | 10-20 | 10-20 | 10-20 |

Width of product | mm | 640-1040 | 640-1040 | 640-1040 | 640-1200 | 1000-1350 |

Cutting method |

| Single cutter | Double cutter | |||

Thickness of product | mm | 1.0-3.0 | 1.0-4.0 | 1.0-4.0 | 2.0-5.0 | 2.0-5.0 |

Cooling method |

| Cooled by wind and water | ||||

Output | kg/h | 50-90 | 160-240 | 200-280 | 280-360 | 450-650 |

Installed power | kw | 140 | 200 | 220 | 260 | 400 |

Dimensions(L×W×H) | m | 26×4.0×2.8 | 30×4.1×2.8 | 36×4.2×3 | 38×4.2×3.2 | 28x5.2x3.2 |

Total weight | T | 10 | 13 | 14 | 16 | 23 |

Main technical parameters

Model | Unit | TY-1040 | TY-1380 |

Max. forming area | mm2 | 1000×1100 | 1100x1380 |

Max. forming depth | mm | 80 | 100 |

Production efficiency | s/die | 3 - 5 | 3 - 5 |

Forming pressure | T | 15 | 15 |

Mounted power | kw | 168 | 204 |

Total weight | T | 15 | 16 |

Installation size | m | 12×2×2.6 | 15x3.6x2.58 |

Main technical parameters

Model | Unit | TY-180+120/100 |

Screw diameter | mm | 180+120/100 |

Motor | kw | 22 |

Heater | kw | 25 |

Extruder capacity | kg/h | 80-130 |

Cooling water tank | mm | 2000×410×280 |

Granule cutting motor | kw | 2.2Packaging & Shipping |