Автоматическая термоусадочная упаковочная машина для бутылок с напитками 0-10

- Категория: Wrapping Machines >>>

- Поставщик: Zhangjiagang,City,Fillpack,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.5 $* | 0.38 $* |

| Aug-18-2025 | 0.55 $* | 0.78 $* |

| Jul-18-2025 | 0.56 $* | 0.11 $* |

| Jun-18-2025 | 0.43 $* | 0.15 $* |

| May-18-2025 | 0.60 $* | 0.40 $* |

| Apr-18-2025 | 0.27 $* | 0.25 $* |

| Mar-18-2025 | 0.91 $* | 0.74 $* |

| Feb-18-2025 | 0.1 $* | 0.52 $* |

| Jan-18-2025 | 0.29 $* | 0.79 $* |

Характеристики

(In stock for sale now!) 0-10pcs/min production speed automatic Shrink packing machine for beverage bottle

Items are in stock and ready to ship.

Voltage:3PH 380V 50Hz

Product description

● Frequency converter speed adjust、two segment convey device.

● Bottle pushing, thermo sealing and cutting whole movement adopt to pneumatic fracture.

● Proximity switch control film length.

● Touch screen, PLC system greatly increase facility movement reliability.

● Double-wind recycle fan machine, ensure shrinkage tunnel inside even temperature.

● Super big wind-volume cooling system, ensure quickly get into shape .

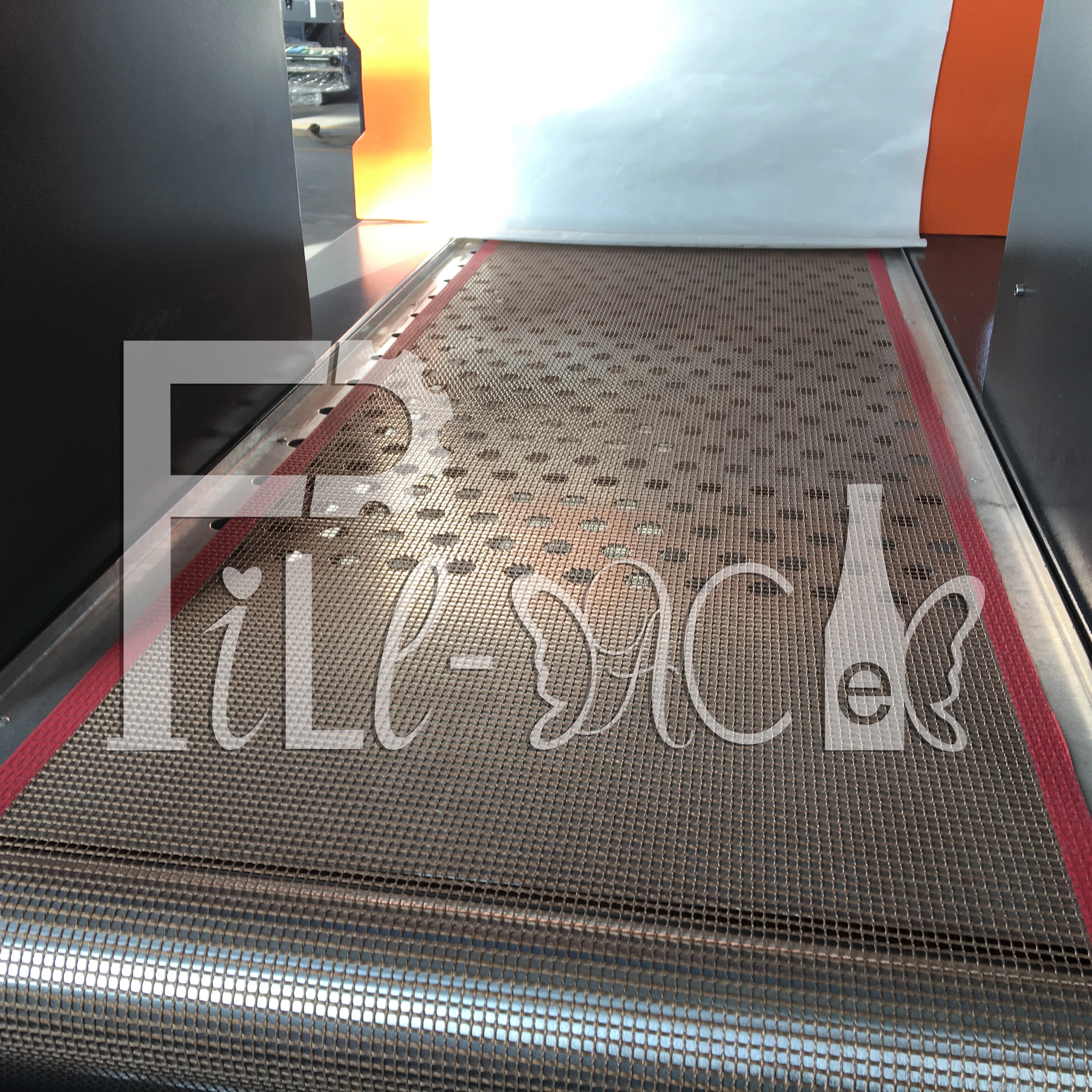

● Anti-high temperature teflon convey belt, convey steadily, high-strength anti-abrasion.

● Frequency limitless speed adjust convey belt frame.

● Convey belt height can make according client requirement, adjust range:±50mm

● Bottle convey machine can meet with client bottle forward direction requirement, can lengthen or shorten.

● Wing stainless steel heating system, endurance.

● Meet with product instant stop requirement product-bearing rack device ensure production line consistency.

Function

1. Auto convey fracture; joint filling machine convey belt, divide two passage or one passage, control via frequency converter, speed adjust freely, can auto divide and sort bottles .

2. Automatic film wrappage fracture, cam complete wrappage auto film covering and sealing, cutting function.

3. Auto thermo shrinkage cooling fracture, can auto contraction and cooling function after film covering.

Production procedure for bottle shrink wrapper

Wrappage from single-line 90°change to multi-line again divide 1、2、3、4 line via bottle division board, via the front 1、2、3、4 bottle separately reach photoelectric inspection, convey belt stop, place-limit gas-cylinder work, wrappage was conveyed to cutting and sealing machine to seal and cut, wrappage was conveyed to contraction machine to contract via convey device, again convey to stock rack via cooling convey belt, when the first bag convey to contraction machine, the second bag auto arrange, then conveyed to sealing and cutting machine via pushing cylinder, again repeat the first bag recycle procedure.

Technical parameter | ||

suitable max size | D 25-120mm, H 30-250mm | |

shrinkage film size | PE、PVC、POF | |

shrinkage thermo thickness | 0.03-0.15mm | |

thermo shrinkage tunnel temperature | 160 - 260°can adjust at will. | |

pressure requirement | 380/220V | |

facility weight | 1.2T | |

fan machine | 1.1Kw 2set 380V, 65W 4set 380V | |

Technical condition and requirement

1. Package type

(1)350/500/550/600ML big bag:4×6,4×5 ;small bag、3×4,3×5 four type of package.

(2)1L/1.5L/2L/2.5L big bag:3×3,3×4;small bag、2×2,2×3 four type of package

2. Regarding can, we suggest adopt to package with tray, pack steadily.

3. Meet with pre-treatment filling speed of filling machine.

(1) 350/500/550/600ML big bag:4×6,4×5,(12000-15000b/hr)、small bag:3×5,3×4,(8000-10000b/hr).

(2)1L/1.5L/2L big bag:3×4,3×3(5000-6000b/h)、 small bag:2×3,2×2(3000-4000b/hr).

Solution for bottle shrink wrapper

1. According production line, auto arrange, and combine our company MB-150A automatic sealing and cutting mature structure, as the machine fracture.

2. The production line can match with any company filling device. For it stability, the production line main component all adopt to import, joint venture famous brand.

3. If pre-treatment filling machine output is comparatively high, can divide two-way, auto seal and cut at the same time, to meet with output requirement, among WD-150A fracture has original creation, it is the highest-efficiency, highest economical collocate at the same time.

4. PE film adopt to flake, upper and down roll, auto seal and cut to roll type and up to shrinkage efficiency.

10 pcs/min teflon conveyor bottle shrink wrapper for juice / cola

Facility basic configuration

● Stainless steel wing heating tube 12 piece.

● China-America cooperation Teflon convey belt.

● Shanghai Hemei electric-motor and Zhejiang Taili worm speed-regulation machine.

● South-Korea Autonics photoelectric switch, proximity.

●Thermo sealing knife aluminium-mould heating board, even temperature, long life, our company special production.

● Whole bottle shrink wrapper plastic-sprayed, machine rack adopt to high-quality carbon steel, main part adopt to stainless steel.

● Bottle convey machine length:2600mm.

● Carton and wrappage film pack separately.

Full piece bottle inlet belt chain to suit all kinds of bottles:

Bottle cylinder holding system to make sure one pack stability:

Whole piece bottle pack transmission board to make sure transmission stability:

Teflon mesh for stable moving:

Samples for bottle shrink wrapper

Guarantee

We response for one year warranty for the bottle shrink wrapper, however, it without any human conduct. And provide one-year free spare part for client. And send engineer to client’s company with client’s provision for flight charge and accommodation. Help install the machine, teaching their staff operate the machine and also, we do have a private school which help our client sending their staff to china, help them training.

1. The bottle shrink wrapper is packed by wooden case.

2. The delivery date of bottle shrink wrapper is within 7 days after payment.

Major in International business from XiaMen University ,15 years’ experience in foreign trade,10 years'experience in filling-packing machinery

Whatsapp/Wechat: +8615862615333

E-mail: admin@fillpackmachine. com

Major in engineering,3 years'filling packing machine experience

Whatsapp/Wechat: +8617372553512

E-mail: sales3@fillpackmachine. com

4 years' foreign trade experience

Whatsapp/Wechat: +8617372553526

E-mail: sales6@fillpackmachine.com

3 years experience in mechanical foreign trade, serving every customer with my heart.

Whatsapp/Wechat: +8617372553513

E-mail: sales4@fillpackmachine.com

8 years experience in foreign trade, work seriously, serve customers positively and enthusiastically.

Whatsapp/Wechat: +8617372553517

E-mail: sales7@fillpackmachine.com

E-mail:sales5@fillpackmachine.com

ZhangJiaGang City FILL-PACK Machinery Co.,Ltd. is loacated in Zhangjiagang city which is famous for beverage machinery producer collection. Intergrated the industry advantange and its own development in R&D, production, sales, after sales service, FILL-PACK is ready to serve more and more customers with our full range products and satified service.

FILL-PACK product is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant(pure drinking water, mineral water, carbonated drinks, juice, tea and beer, etc.)

Customer's service:

1. FILL-PACK company can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have professional design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.