6YL 95 эффективная машина для прессования подсолнечного масла новейшая полуавтоматическая

- Категория: Oil Pressers >>>

- Поставщик: Tacheng,City,Xinchen,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 1961.72 $* | 2059.24 $* |

| Aug-15-2025 | 1945.88 $* | 2042.57 $* |

| Jul-15-2025 | 1632.77 $* | 1714.24 $* |

| Jun-15-2025 | 1912.84 $* | 2008.30 $* |

| May-15-2025 | 1664.9 $* | 1747.95 $* |

| Apr-15-2025 | 1879.27 $* | 1973.6 $* |

| Mar-15-2025 | 1862.63 $* | 1955.80 $* |

| Feb-15-2025 | 1846.70 $* | 1938.96 $* |

| Jan-15-2025 | 1829.67 $* | 1920.1 $* |

Характеристики

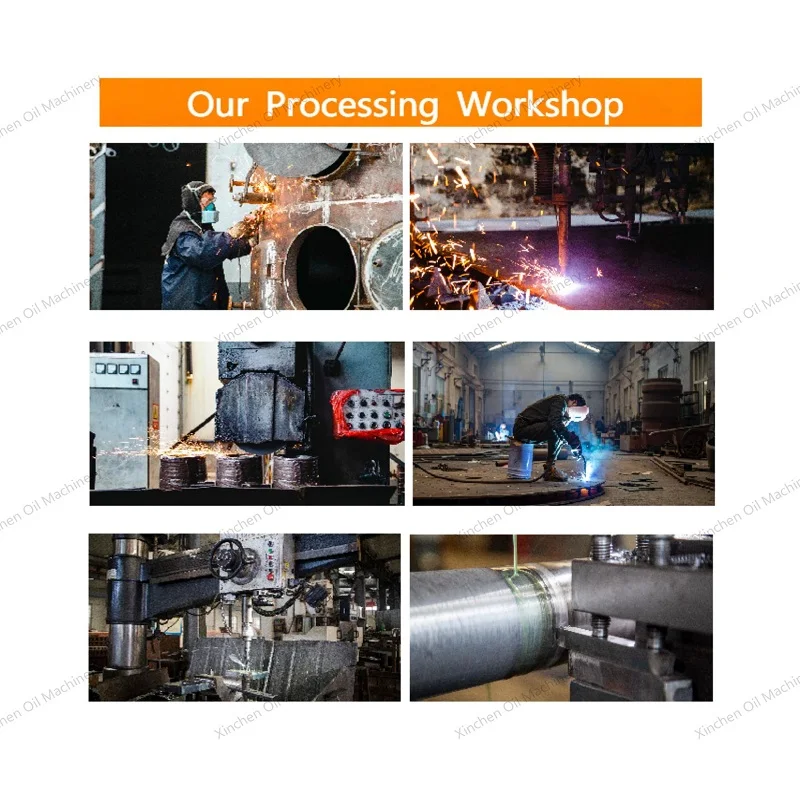

Professional Oil Machinery Supplier in China

70 years of mature production technology experience; 14 years of export experience.

We can 100% bring high-quality machines and good service to you.

We can 100% bring high-quality machines and good service to you.

Product description

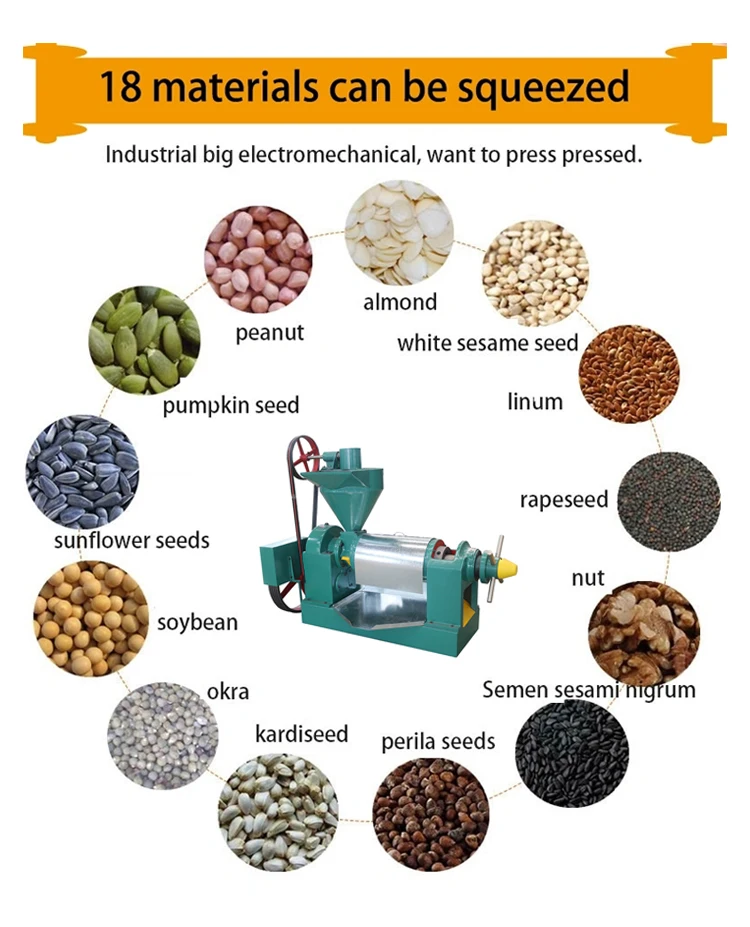

Oil Seeds | Supports multiple oil material: Sunflower, Cotton Seeds, Coconut, Copra, Flax Seed, Sesame, Olive, Avocado, etc | ||||||

Application | Commercial, Factory, Farms, Agricultural Machinery | ||||||

Type | Single Screw Cold / hot Third Scale Stage Oil Press Machine Pressers | ||||||

The 6YL-95Y oil press machine already produced 70 years, therefore this small machine with mature technology and perfect structure, save the maintaining time, stronger pressure with higher oil yields.

The special design is we used the environmental protection material spray on the machine surface.

In addition, gear case of the machine adopt helical tooth design to make it with strong torsion and lower noise.

It is easy to operate, sturdy and durable, easy to maintain and so on.

The oil press equipment suitable for squeezing various vegetable oils such as rapeseed, cottonseed, soybean, peanut kernel, flax seed, tung seed, kardiseed, sunflower seed and palm kernel.

Customer Cases

The solution of the entire production line needs to be based on the customer's plant drawings, material quality and requirements for refined oil. The following plan is for the production line of the Kazakhstan customer to produce sunflower oil, for reference only.

1. At the beginning of the plan, our engineer team designed the necessary equipment (vibrating screen, stone remover, permanent magnet cylinder, conveyor belt, hoist, oil press, oil filter, refining equipment) based on the basic information provided by the customer. The customer wants to save money after checking the quotation, so our engineer recommends that the customer buy cleaner materials directly to reduce the cost of front-end cleaning equipment.

2. In the middle of the plan, the customer provided a product oil composition table and wanted to increase the oil yield. The engineer suggested that the customer add a steamer to achieve the effect.

3. In the later stage of the program, the customer felt that the profit obtained as an oil wholesaler was not high, and wanted to increase the profit. The engineer team suggested that the customer add a filling machine to fill the large barrel of oil into the small bottle and label it. This can increase the price of oil and increase more profits. We provide customers with filling machines, blow molding machines, plastic bottles, and all other needs, saving customers a lot of energy and time, providing a one-stop shop service.

Company profile

Customer

Packing & Shipping

FAQ

Q: Why work with your company ?

A: We have 14 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.

Q: How can I judge your machine quality ?

A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.

Q: If i don't know how to operate this machine ? How can i do ?

A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.

Q: What's wear-in for new machine?

A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.

1. 1st hour, adjust oil cake thickness as 3 mm.

2. 2nd hour, adjust oil cake thickness as 2.5 mm.

3. 3rd hour, adjust oil cake thickness as 2 mm.

Q:What are cold press and hot press?

A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.

Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.

Q:What service do you provide?

A: (1) 1 year free warranty, whole lifetime maintenance.

(2) Supplying wearing parts all year around.

(3) Supplying technical solutions at any time.

(4) Helping design and plan the oil plants construction.

(5) Providing installation video.

(6) Developing agents with good policies around world.

Q: How can I get a quotation?

A: Contact us immediately for further details by sending us an inquiry.

A: We have 14 years experience in oil press machine industry, and we can help you find a great solution that can save your cost and reach your production targets. Our main products including :screw oil press, oil filter, oil refinery machine and spare parts etc.

Q: How can I judge your machine quality ?

A: Actually we already got good reputations in Russia and The Five Countries in Central Asia because of our service and stable quality. All of our machines can provide 1 year warranty and lifetime maintenance, for core parts are 6 months warranty.

Q: If i don't know how to operate this machine ? How can i do ?

A: Our engineer will help you from the starts, and machine has been tested and fully assembled before shipping, you just needs to make 2-4 hours wear-in and then can work.

Q: What's wear-in for new machine?

A: Using 10 KG oil cake + 1 KG sand + 1 KG water, mix them, put in oil press, wear in 3~4 hours.

1. 1st hour, adjust oil cake thickness as 3 mm.

2. 2nd hour, adjust oil cake thickness as 2.5 mm.

3. 3rd hour, adjust oil cake thickness as 2 mm.

Q:What are cold press and hot press?

A: Cold press is pressing dry and raw seeds. usually need to press 2 times to get maximum oil.

Hot press is pressing roasted seeds. usually only 1 time to get maximum oil. peanuts roast to 125~130 degree with 1~2% moisture.

Q:What service do you provide?

A: (1) 1 year free warranty, whole lifetime maintenance.

(2) Supplying wearing parts all year around.

(3) Supplying technical solutions at any time.

(4) Helping design and plan the oil plants construction.

(5) Providing installation video.

(6) Developing agents with good policies around world.

Q: How can I get a quotation?

A: Contact us immediately for further details by sending us an inquiry.

Contact Us