Полуавтоматическая машина для выдувного формования бутылок из ПЭТ/выдувание напитков/производственное

- Категория: Stretch Blow Moulding Machines >>>

- Поставщик: Zhangjiagang,City,Fillpack,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.31 $* | 0.31 $* |

| Aug-18-2025 | 0.70 $* | 0.74 $* |

| Jul-18-2025 | 0.15 $* | 0.73 $* |

| Jun-18-2025 | 0.51 $* | 0.2 $* |

| May-18-2025 | 0.35 $* | 0.5 $* |

| Apr-18-2025 | 0.13 $* | 0.10 $* |

| Mar-18-2025 | 0.54 $* | 0.37 $* |

| Feb-18-2025 | 0.6 $* | 0.97 $* |

| Jan-18-2025 | 0.34 $* | 0.44 $* |

Характеристики

Semi-automatic PET bottle blow molding machine/drink bottle blowing/production equipment

semi auto 1200 bottle output drink bottle production equipment

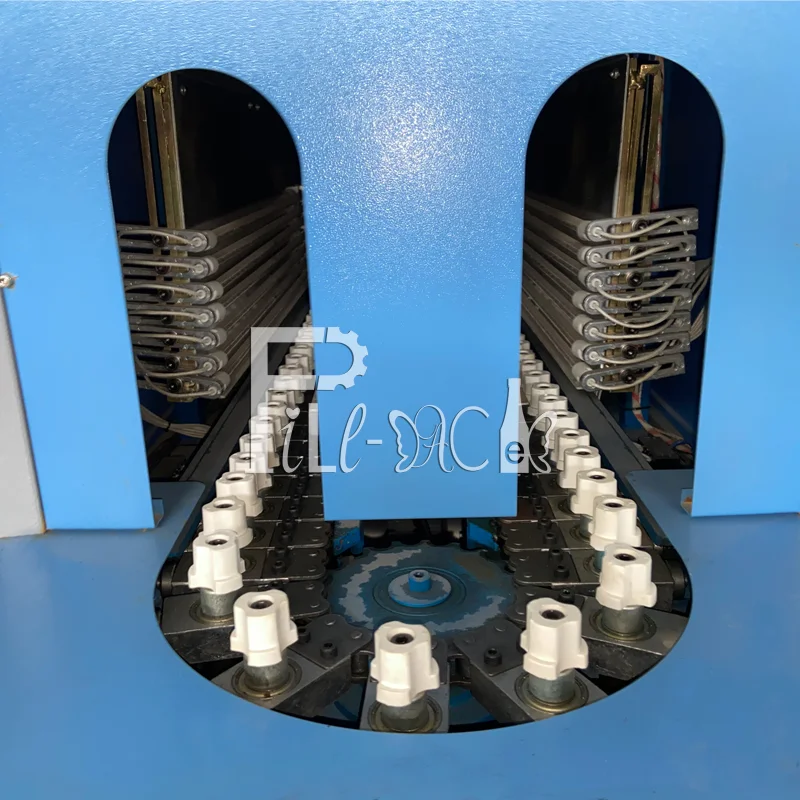

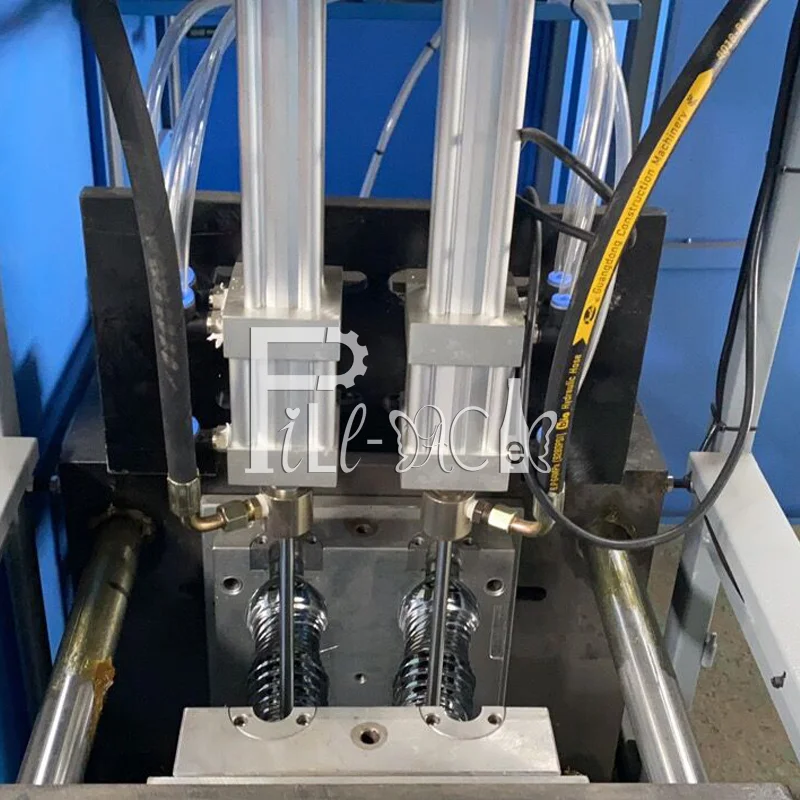

FP-1200A type is semi auto drink bottle production equipment. It has 2 cavity, semi automatic, the mold can be customized. DY-1200A drink bottle production equipment is suitable for producing PET plastic containers and bottles from 10-2000ml. It is widely used to produce the carbonated bottle, mineral water, carbonated drink bottle, pesticide bottle, oil bottle, cosmetics wide-mouth bottle etc.

Model | FP-1200A | FP-1200B | FP-500 | FP-500II | FP-120 | FP-1200N | |||

Molding | Clamping force | kg | 13000 | 13000 | 25000 | 45000 | 6000 | 13000 | |

Clamping stroke | mm | 155 | 155 | 220 | 220 | 360 | 155 | ||

Stretcing stroke | mm | 370 | 370 | 400 | 400 | 450 | 370 | ||

Bottom stroke | mm | / | / | / | / | / | / | ||

Canity pitch | mm | 130 | 130 | 130 | 300 | / | 130 | ||

Number of Cavity | Cavities | 2 | 2 | 1 | 2 | 1 | 2 | ||

Max.container volume | Itr | 2 | 2 | 6 | 6 | 20 | 1.5 | ||

Neck.container range | mm | 10-120 | 10-120 | 10-120 | 10-120 | 30-120 | 10-120 | ||

Max.container diameter | mm | 130 | 130 | 200 | 120 | 300 | 90 | ||

Max.container height | mm | 350 | 350 | 380 | 200 | 430 | 350 | ||

Carriage unit | pcs | 72 | 96 | 72 | 96 | 19 | 72 | ||

Theoretical output | bph | 1200 | 2400 | 500 | 1000 | 150 | 600 | ||

Total power | kw | 17 | 17 | 17 | 17 | 39 | 17 | ||

Heating power | kw | 16 | 16 | 16 | 16 | 38 | 16 | ||

Max.herating power | kw | 8 | 8 | 10 | 10 | 20 | 10 | ||

1. Perfect function with economic investment.

2. Saving power and uneasy to worn out, Adopting new double crank four bars to lock mould, the cross fixed. Providing high pressure blowing system.

3. No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

4. Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

5. Strong clamping force with high pressure and double crank links to lock the mold.

6. Safe, reliable, and unique design of the position of valve to make the air pressure diagram of the machine easier to

understand.

7. Low cost, high efficiency, easy operation, easy maintenance, etc.

8. Ideal effect of the chilling with the chilling system.

9. Easy to operate and maitain, operation by one person.

10. Adopting double crank to adjust mould, heavy locking mould, stable and fast, adopting infrared oven to heat the perform, the perform rotated and heated equally.

11. The air system has been divided into two parts: pneumatic action part and bottle blow part to meet the different requirements

for the action and blow. It can provide sufficient and steady high pressure for blowing large irregular shaped bottles.

12. The machine is also equipped with muffler and oiling system to lubricate the mechanical part of the machine.

13. The machine can be operated in the step-by-step mode and the semi-auto mode.

14. The machine is small with low investment, easy and safe to operate.

15. The bottle rejection rate is less than 0.2%.

Items | Components | Model |

1 | Blow Moulding Machine | FP-1200A |

2 | Preform Unscramble | FP-1200A |

3 | HP Air Compressor | 0.65 M3/min 30kg |

4 | Air Filters | 2.0M3/min 30kg |

5 | Blow Mould | 500ml |

1. the machine is packed by wooden case.

2. The delivery date is within 30 days after payment.

3L / 5L / 10L mineral water plastic bottle 2 in 1 bottling equipment / plant / machine / system / line

mineral water bottling machine

Mineral Drinking / Drinkable water UF / Hollow fibre ultra purification equipment / plant / machine / system / line

PET plastic glass 3 in 1 monobloc gas drink beverage water wine bottle filling machine / equipment / line / plant / system

Customer's service:

1. FILL-PACK company can provide turn-key project for you, only you have any idea to start beverage factory plant.

2. FILL-PACK company have professional design team, our engineer can draw bottle samples and flow chart ofworkshop for you .

3. FILL-PACK company give you the best quotation for all kinds of beverage production, only you can tell me whichkind of drink you want to product, what is your capacity(how many bottles one hour) what is you bottle material, pet or glass,etc

After service:

1. We send the engineers to help installing, commissioning and training, the engineers start from our factory area.

2. We supply below necessary documents with the machine:

a. Machine layout

b. Electricity diagram

c. Machine certificate

d. General manual book/maintenance book

3. After one year guarantee, the seller provides payable spare parts and technician's VISITING maintenance service.

ZhangJiaGang City FILL-PACK Machinery Co.,Ltd. is loacated in Zhangjiagang city which is famous for beverage machinery producer collection. Intergrated the industry advantange and its own development in R&D, production, sales, after sales service, FILL-PACK is ready to serve more and more customers with our full range products and satified service.

FILL-PACK product is very critical in the choice of raw materials and spare parts. Korea 304 /316 stainless steel plate, ABB, SEW motors, Siemens, Mitsubishi, OMRON electrical control components, FESTO CAMOZZ the control valve, as well as international precision machining center for the fine quality of the machine foundation.

We are the supplier who can design and manufacture for all kinds beverage production plant(pure drinking water, mineral water, carbonated drinks, juice, tea and beer, etc.)

Ms ALICE GU

Language: English-Chinese

Major in International business from XiaMen University 15 years’ experience in foreign trade

Whatsapp/Wechat: +8615862615333

E-mail: admin@fillpackmachine. com

Mr TONY XU

Language: English-Chinese

Major in engineering,3 years'filling packing machine experience

Whatsapp/Wechat: +8617372553512

E-mail: sales3@fillpackmachine. com

Ms Suger Liu

Language: English-Chinese4 years' foreign trade experience

Whatsapp/Wechat: +8617372553526

E-mail: sales6@fillpackmachine.com

Whatsapp/Wechat: +8617372553513

E-mail: sales4@fillpackmachine.com

8 years experience in foreign trade, work seriously, serve customers positively and enthusiastically.

E-mail: sales7@fillpackmachine.com

Whatsapp/Wechat: +8617372553513

E-mail: sales4@fillpackmachine.com