2021 промышленная газовая горелка плавильная печь для алюминия 5000

- Категория: Industrial Furnace >>>

- Поставщик: Wuxi,Wondery,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.66 $* | 0.69 $* |

| Aug-16-2025 | 0.77 $* | 0.2 $* |

| Jul-16-2025 | 0.11 $* | 0.5 $* |

| Jun-16-2025 | 0.43 $* | 0.31 $* |

| May-16-2025 | 0.39 $* | 0.54 $* |

| Apr-16-2025 | 0.5 $* | 0.61 $* |

| Mar-16-2025 | 0.19 $* | 0.4 $* |

| Feb-16-2025 | 0.82 $* | 0.19 $* |

| Jan-16-2025 | 0.48 $* | 0.6 $* |

Характеристики

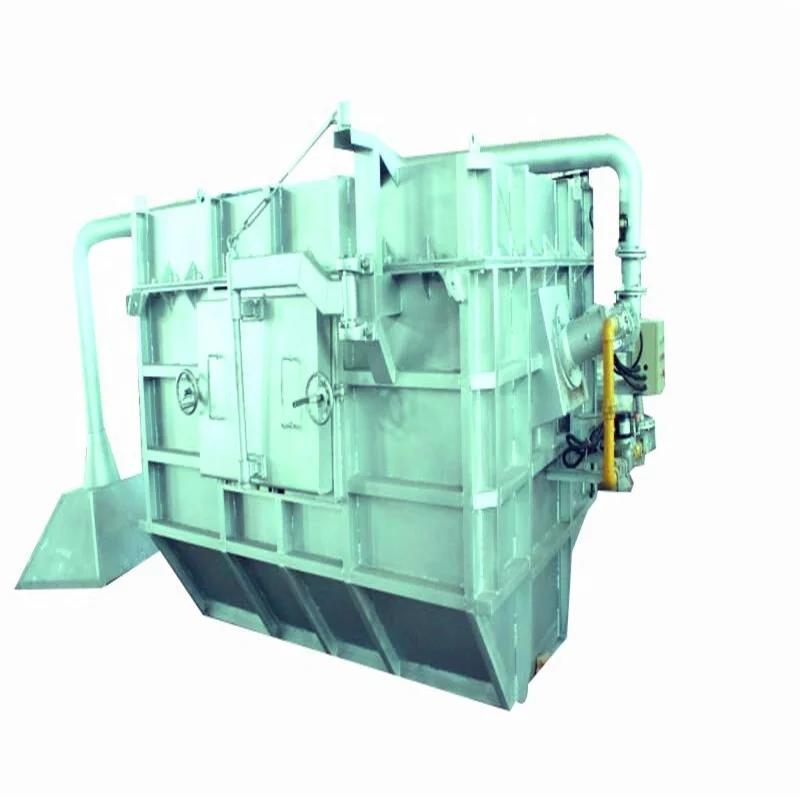

Product Application

The gas fired reverberatory type aluminum melting furnace has a compact structure for melting. The melting pool is formed by once-forming casting material, which has a high strength and a long service life. The furnace employs famous burner brand, which has functions of automatic ignition and temperature control. The furnace also has over-temperature alarm device.

cans recycling machine cans recycling machine cans recycling machine cans recycling machine cans recycling machine

SPECIFICATION FOR Reverberatory Aluminum Melting Furnace Oil Fired Industrial Furnace Cans Recycling Machine | ||||

Furnace parameter | Model | CX-RJL-5000 | ||

Melting pool capacity | 5000kg aluminum | |||

Melting rate | about 2000kg/hour (at continuous working status) | |||

Power | 220V, ±10%, 50HZ ( or customized) | |||

Rated working temperature | 850℃ (atmosphere temperature) | |||

Temperature uniformity | ±10℃ (aluminum liquid) | |||

Fuel | Type | Natural gas | ||

Calorific value | 8400Kcal/m3 | |||

Consumption | 55kg/ton copper | |||

Furnace lining | Castable material | 860AC and 84ACX (Allied Mineral Product) | ||

Heat preservation material | high-alumina bricks | |||

Burning system | Burner | SINON | ||

Burning controller | Honeywell | |||

Combustion-supporting fan | Domestic | |||

Temperature controller | Taisee | |||

Temperature control | Automatic temperature control flame switch | |||

over-temperature alarm | ||||

flame-out protection | ||||

Main Features

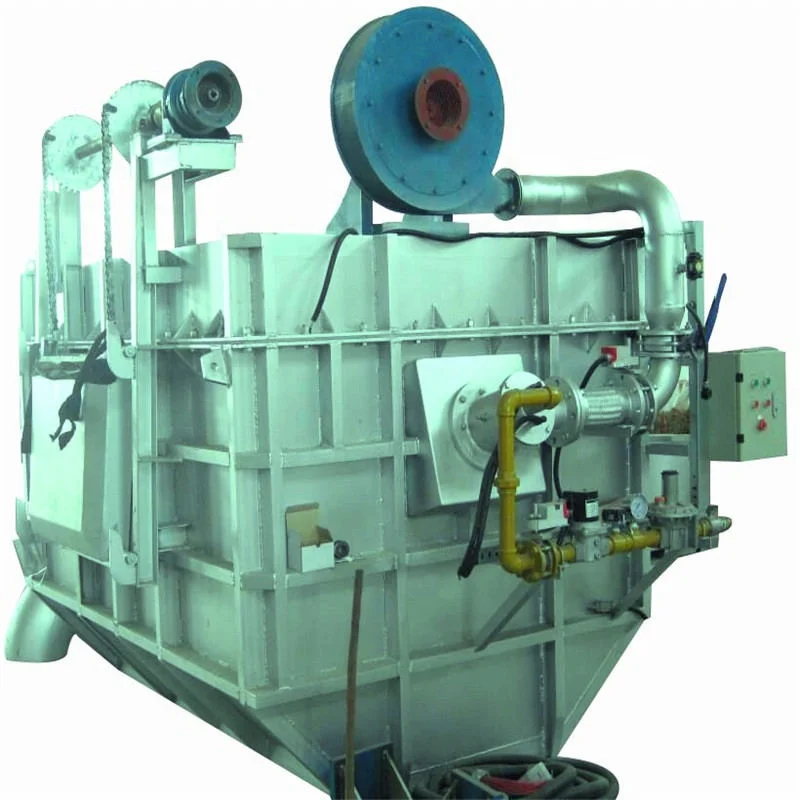

Name: Lining Building

Brand: Allied Mineral Product (Tianjin) Co., Ltd

The castable material is 860AC and 84ACX, which has the advantages of high strength, non-adhering with molten zinc, easiness to be cleaned, and long service life.

Aluminum Melting Furnace 2 Tons

Machine Parts

Name: Discharging chute

The chute is used for discharging the zinc solution out of the furnace.

Aluminum Melting Furnace 2 Tons