Кол-во серии Большой Размер порта регулируемой длины высокого давления воздуха обработки исходных текстов регулятор происхождения Профессиональное качество

- Категория: Pressure Regulators >>>

- Поставщик: Shenzhen,Splinktech,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.57 $* | 0.76 $* |

| Aug-20-2025 | 0.14 $* | 0.87 $* |

| Jul-20-2025 | 0.56 $* | 0.6 $* |

| Jun-20-2025 | 0.39 $* | 0.25 $* |

| May-20-2025 | 0.83 $* | 0.35 $* |

| Apr-20-2025 | 0.35 $* | 0.23 $* |

| Mar-20-2025 | 0.64 $* | 0.54 $* |

| Feb-20-2025 | 0.87 $* | 0.71 $* |

| Jan-20-2025 | 0.98 $* | 0.82 $* |

Характеристики

Product Description

Specification

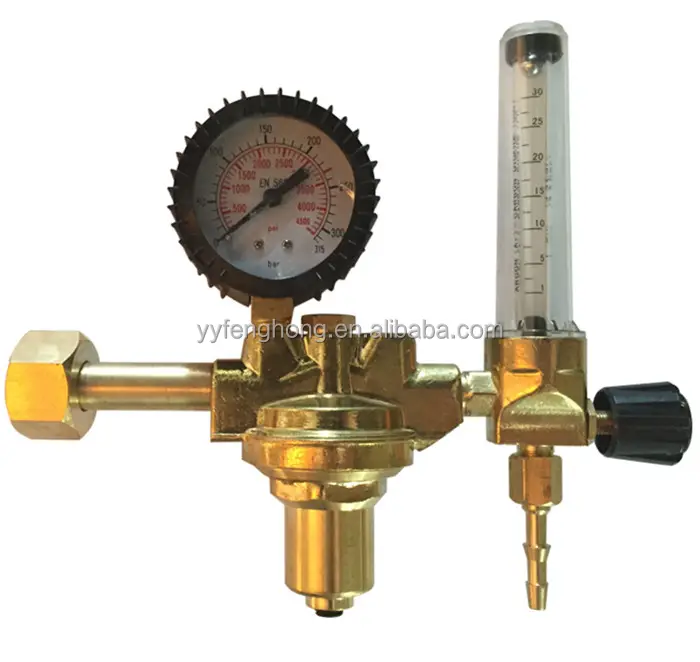

Product name: Buoy type·oxygen inhaler

Input pressure: <15Mpa

Output pressure: 0.25Mpa

Flow adjustment range: 1-10L/min

Safety valve: 0.5Mpa automatic exhaust

Imported thread: G5/8''

Export thread: M12x1

Equipped with humidification bottle device

use

It is mainly used in the oxygen supply system of the medical center, which is used by medical units to give oxygen and hypoxic patients for oxygen inhalation, scientific research institutions, industrial and mining and other inhalation flow control devices. The flow rate of the oxygen inhaler is accurate, convenient and safe to use. It is an essential device for oxygen therapy for patients in hospital emergency rooms and wards

working principle

The role of the oxygen inhaler is to provide a continuous constant pressure and flow of oxygen for patients to use. The bottle plug-in oxygen inhaler uses its own pressure reducing device to reduce the high pressure in the oxygen cylinder (15Mpa pressure when the bottle is full) to a low pressure suitable for human use (0.2~0.2Mpa), and then output to the human body after being moistened by water . Since the wall plug-in oxygen inhaler has an input pressure of 0.2~0.4Mpa, it does not need to be decompressed and can be directly output to the human body.

Operation method:

1. Add distilled water to the humidification cup. The water level in the bottle cannot be higher than the upper water line, but not lower than the lower water line. It is forbidden to use normal saline instead.

2. Before inserting the inhaler into the oxygen supply terminal socket, you should turn off the flow adjustment switch and adjust the direction of the oxygen quick plug, and then insert the quick plug into the oxygen supply terminal socket. When you hear a "click" sound and see the oxygen supply terminal When the locking sleeve of the socket slides automatically, it indicates that the quick plug and the oxygen supply terminal socket have been connected and locked.

3. Before supplying oxygen, insert the oxygen inhalation tube into the oxygen supply connector, and then turn the flow adjustment switch counterclockwise to turn on the origin, so that the float rises slowly (the scale line aligned with the center of the float is the flow reading, and the unit is liters/min) , The oxygen supply can be adjusted according to needs.

4. During the oxygen supply process of the inhaler, if the water in the inhaler bottle is below the lower water line, the flow adjustment switch should be closed in time, the humidification bottle should be unscrewed, and distilled water should be added according to the requirements of Article 1 of this item. Screw on the body of the inhaler and continue oxygen supply.

5. When the inhaler is not in use, the air source of the inhaler should be turned off; if you need to take it off, hold the inhaler with your hand and take it off after proceeding (the engineering installation unit is responsible for the explanation of the unlocking method of different oxygen supply terminal sockets), and then After the water in the bottle is cleaned and disinfected, it is stored in a non-corrosive and well-ventilated room).

Input pressure: <15Mpa

Output pressure: 0.25Mpa

Flow adjustment range: 1-10L/min

Safety valve: 0.5Mpa automatic exhaust

Imported thread: G5/8''

Export thread: M12x1

Equipped with humidification bottle device

use

It is mainly used in the oxygen supply system of the medical center, which is used by medical units to give oxygen and hypoxic patients for oxygen inhalation, scientific research institutions, industrial and mining and other inhalation flow control devices. The flow rate of the oxygen inhaler is accurate, convenient and safe to use. It is an essential device for oxygen therapy for patients in hospital emergency rooms and wards

working principle

The role of the oxygen inhaler is to provide a continuous constant pressure and flow of oxygen for patients to use. The bottle plug-in oxygen inhaler uses its own pressure reducing device to reduce the high pressure in the oxygen cylinder (15Mpa pressure when the bottle is full) to a low pressure suitable for human use (0.2~0.2Mpa), and then output to the human body after being moistened by water . Since the wall plug-in oxygen inhaler has an input pressure of 0.2~0.4Mpa, it does not need to be decompressed and can be directly output to the human body.

Operation method:

1. Add distilled water to the humidification cup. The water level in the bottle cannot be higher than the upper water line, but not lower than the lower water line. It is forbidden to use normal saline instead.

2. Before inserting the inhaler into the oxygen supply terminal socket, you should turn off the flow adjustment switch and adjust the direction of the oxygen quick plug, and then insert the quick plug into the oxygen supply terminal socket. When you hear a "click" sound and see the oxygen supply terminal When the locking sleeve of the socket slides automatically, it indicates that the quick plug and the oxygen supply terminal socket have been connected and locked.

3. Before supplying oxygen, insert the oxygen inhalation tube into the oxygen supply connector, and then turn the flow adjustment switch counterclockwise to turn on the origin, so that the float rises slowly (the scale line aligned with the center of the float is the flow reading, and the unit is liters/min) , The oxygen supply can be adjusted according to needs.

4. During the oxygen supply process of the inhaler, if the water in the inhaler bottle is below the lower water line, the flow adjustment switch should be closed in time, the humidification bottle should be unscrewed, and distilled water should be added according to the requirements of Article 1 of this item. Screw on the body of the inhaler and continue oxygen supply.

5. When the inhaler is not in use, the air source of the inhaler should be turned off; if you need to take it off, hold the inhaler with your hand and take it off after proceeding (the engineering installation unit is responsible for the explanation of the unlocking method of different oxygen supply terminal sockets), and then After the water in the bottle is cleaned and disinfected, it is stored in a non-corrosive and well-ventilated room).

Packing & Delivery

Company Profile

Our Services

FAQ