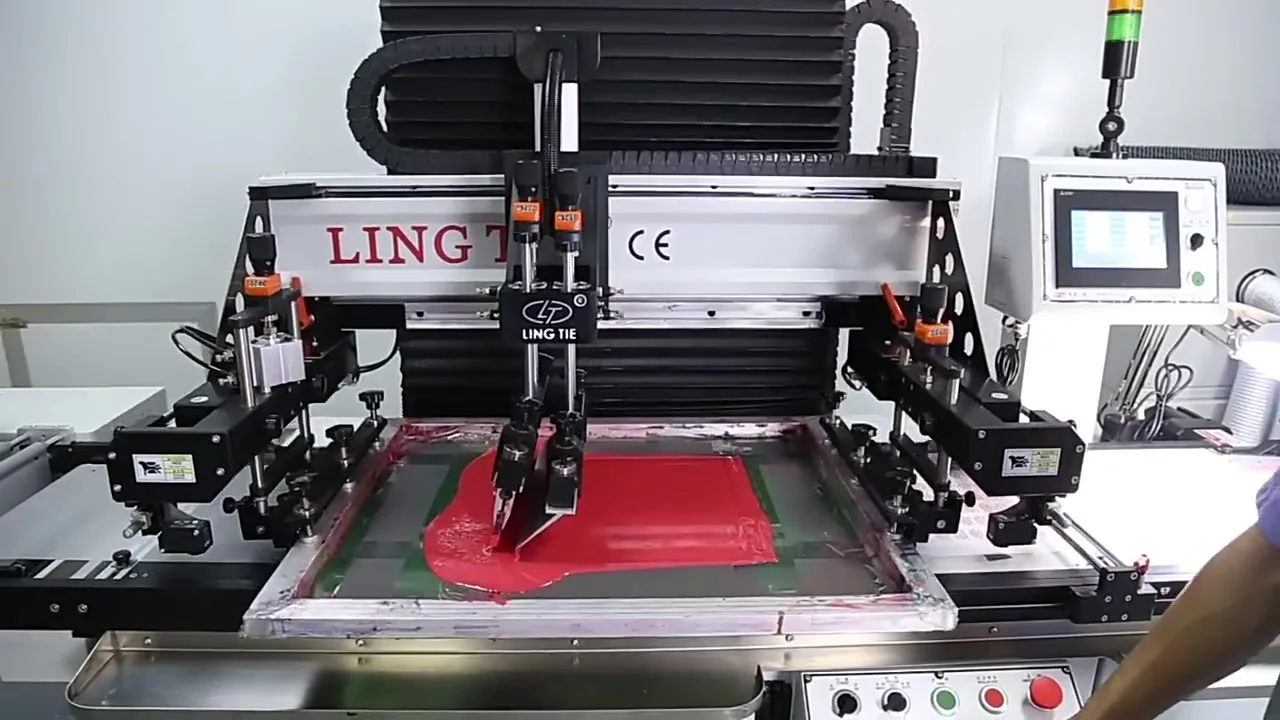

2 цвет шелк трафаретная печатная машина для трафаретной

- Категория: Screen Printers >>>

- Поставщик: Lingtie,(Xiamen),Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.62 $* | 0.31 $* |

| Aug-15-2025 | 0.45 $* | 0.39 $* |

| Jul-15-2025 | 0.5 $* | 0.99 $* |

| Jun-15-2025 | 0.33 $* | 0.83 $* |

| May-15-2025 | 0.7 $* | 0.74 $* |

| Apr-15-2025 | 0.77 $* | 0.2 $* |

| Mar-15-2025 | 0.89 $* | 0.10 $* |

| Feb-15-2025 | 0.93 $* | 0.68 $* |

| Jan-15-2025 | 0.11 $* | 0.50 $* |

Характеристики

Products Description

Main Features 1) Automatic screen printing machine printing head is vertical up-and-down for easy change of the silkscreen. 2) Japan servo motors and PLC systems are used in the automatic screen printing machine to ensure high precision and stability. 3) Automatic screen printing machine can feed material, screen printing, drying and rewinding printed material continuously. 4) This automatic screen printing machine has a compact design. It doesn't take much space in your production facility. 5) One operator is enough for the whole production to help you reduce labor cost. Size Information | ||

Model | LTA-4050 | |

Print Area | 430*550mm | |

Print Speed | 0-6000t/h | |

Screen Frame Area | 700*900mm | |

Max. Paper Width | 420mm | |

Inspection Table Max. Size | 500*500mm | |

Air Source | 0.4-0.6mpa | |

Power | 1P 220V 3KW/3P 380V 3KW(Customizable) | |

Printing Material Thickness | 0.02-0.5mm | |

Weight | 1500kg | |

Machine Size | L2620*W1100*H1865mm | |

Application

This machine is mainly used for printing T-shirts and garments.

Other applications

water transfer film, heat transfer films, PVC, PET, PP, PC, PE, BOPP etc all kinds of films, various of nameplate for electronic appliances, membrane switches, panels, soft circuit board, IMD, IML, FPC, rubber vulcanization, non-woven fabric, color labels for cars, ceramic decals, thermal transfer paper, leather, electrostatic film, tetoron, coated paper, adhesive sticker and so on. The thinnest which can be printed is 0.02 mm.

Introduction of the Three Components

Components

This screen printing machine is composed of a feeder, two printing unit and a hot air dryer.

The Feeder

1)It is mainly used to feed all kinds of roll material and cooperate with automatic screen printer.

2)Adopting Japan Mitsubishi frequency converter, automatic control of feeding speed.

3)Feeding machine adopts imported photoelectric switch control, avoid scratching material, can automatically adjust the feeding length.

4)Feeding and winding mechanism utilizes advanced sonar sensor for accurately sensing transparent and non-transparent film.

Technical Parameters | ||||||||

Name | Automatic feeding machine | |||||||

Model | LTC-480B | LTC-600B | LTC-700B | LTC-900B | ||||

Max.Wed Width | 490mm | 610mm | 710mm | 910mm | ||||

Power | 0.3kw | |||||||

Tension | ≤0.1N | |||||||

Weight | 300kg | 320kg | 350kg | 400kg | ||||

Machine Size | L1100*W1000*H1200mm | L1100*W1080*H1200mm | L1100*W1220*H1200mm | L1750*W1250*H1260mm | ||||

Optional functions: 1) Electromagnetic tension control 2) Double-sided dust removal 3) Automatic deviation correction function 4) Electrostatic removal function 5) Tear film function 6) Splice station 7) Anti-scratch device | ||||||||

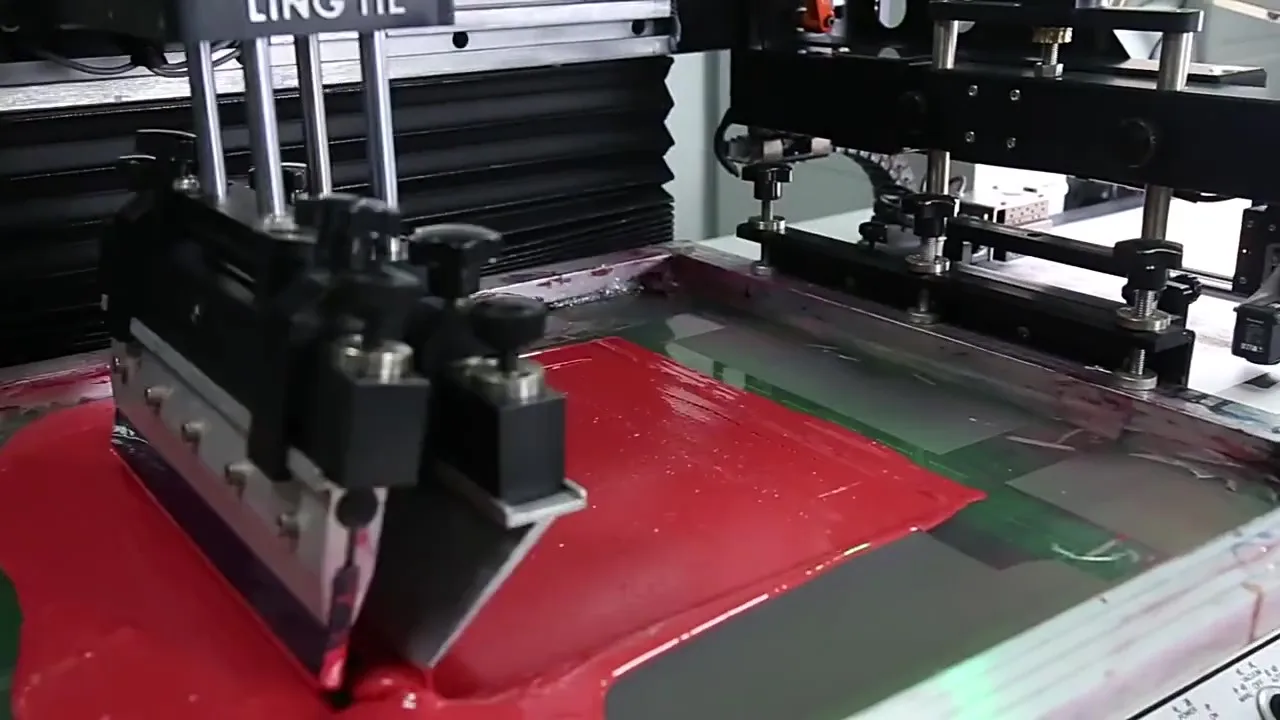

The Printer

1. The printing seat adopts 4-column precise linear guide rail, with high repeatable positioning accuracy, strong stability and durability.

2. With off-screen function, printing a large area of background color and printing glue, to prevent the sticky screen.

3. With anti-drip ink function, prevent color difference between ink with ink, to achieve high quality printing.

4. Equipped with a man-machine system.

Technical Parameters | ||||||

Name | Automatic Roll to Roll Screen Printing Machine | |||||

Model | LTA-4050 | LTA-5070 | LTA-6080 | |||

Print Area | 430*550mm | 530*750mm | 630*850mm | |||

Print Speed | 0-6000t/h | 0-2500t/h | 0-2500t/h | |||

Screen Frame Area | 700*900mm | 800*1100mm | 900*1200mm | |||

Max. Paper Width | 420mm | 520mm | 620mm | |||

Inspection Table Max. Size | 500*500mm | 600*600mm | 700*800mm | |||

Air Source | 0.4-0.6mpa | |||||

Power | 1P 220V 3KW/3P 380V 3KW(Customizable) | |||||

Printing Material Thickness | 0.02-0.5mm | |||||

Weight | 1500kg | 1700kg | 2000kg | |||

Machine Size | L2620*W1100*H1865mm | L2950*W1160*H1865mm | L3150*W1260*H1865mm | |||

Optional functions: 1) Automatic punching function 2) automatic register system 3) dust elimination roller 4) pneumatic frame fixing function 5) CCD optical device | ||||||

The Oven

1. Adopts uniform speed function to ensure that the material stays in the oven at any position for the same time and rewinding speed.

2. Oven with 4 sides, 4 sides heating, air circulation more smooth.

3. Equipped with heat insulation layer, so as not to scald the operator, saving electricity, energy saving and environmental protection.

4. The suction tension can be arbitrarily stepless adjustment, convenient to control the material tension, to ensure that the printing material does not stretch deformation.

3. Equipped with heat insulation layer, so as not to scald the operator, saving electricity, energy saving and environmental protection.

4. The suction tension can be arbitrarily stepless adjustment, convenient to control the material tension, to ensure that the printing material does not stretch deformation.

Technical Parameters | ||||||||

Name | Hot air dryer | |||||||

Model | LTB-350 | LTB-460 | LTB-600 | LTB-800 | ||||

Material quality | Baogang-45#steel plate | |||||||

Power | 14kw | 14kw | 22kw | 22kw | ||||

temperature | Room temperature-140℃ | |||||||

Insulation layer thickness | 50mm | 50mm | 50mm | 100mm | ||||

Temperaturer controller | 2pcs | 2pcs | 4pcs | 4pcs | ||||

Weight | 400kg | 500kg | 600kg | 700kg | ||||

Machine Size | L1970*W780*H1810mm | L1970*W900*H1810mm | L2830*W1060*H2150mm | L3000*W1260*H2260mm | ||||

Optional functions: 1) Uniform speed device 2) Radiator fan 3) Automatic double-side dust elimination 4) Correction device 5) Anti-pull device 6) Laminating device | ||||||||

Humanization Design

Optional Plug

Related Products

Sheet cutting machine

Sheet cutting machine can cut the printed roll into sheets.

UV dryer

UV dryer can initial dry the printed material.

Customer Evaluation

Our Services & Strength

Company Profile