Китайская машина для производства пищевых продуктов собак корма кошек и

- Категория: Pet Food Processing Machines >>>

- Поставщик: Shandong,Arrow,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.33 $* | 0.1 $* |

| Aug-15-2025 | 0.28 $* | 0.29 $* |

| Jul-15-2025 | 0.61 $* | 0.55 $* |

| Jun-15-2025 | 0.3 $* | 0.22 $* |

| May-15-2025 | 0.97 $* | 0.54 $* |

| Apr-15-2025 | 0.21 $* | 0.13 $* |

| Mar-15-2025 | 0.34 $* | 0.33 $* |

| Feb-15-2025 | 0.17 $* | 0.18 $* |

| Jan-15-2025 | 0.29 $* | 0.1 $* |

Характеристики

Product Description

General Desciption: With variety of pets continues increasing, come with the increase on the market demand for the pet food and requirements our company developed various pet food and process line based on market requirement. According to the variety of products, our production line, covers a variety of configurations such as main food, snacks, toys. By changing parameters such as raw materials, temperature, moisture etc parameters, achieved new style products, rich of nutritional content, perfect textures, can meet demand for different pet on adaptability and best taste.

Application: Animal feed, Chew food, Pet treats.

Output: 500kg/h and less, 800~1200kg/h, 1500~2500kg/h, 2500~3500kg/h and 4500kg/h~6000kg/h.

Core Product Specification

AHT Fantastic Technology Double Screw Extruder

(1) Design: Designed by 3D software, analogue simulation, and it is tested by computer automatically, to ensure the requirements of design precision.

(2) Concept: Modular function, humanized system, diversified applications are always our pursuit. AHT Double Screw Extruder under the advanced design concept can meet various demands.

(3) Profession: Our professional manufacturing and processing would ensure the accuracy and coordination among each component of the extruder under the support of the stable processing and low noise.

(4) Precision: Precise food technology and material selection,which assure the working life of the extruder, minimizing the wear and tear of the screw and barrel.

(5) Experience: More than twenty years experience on the domestic and international advanced Double Screw Extruder. We have produced different kinds of extrusion food, like Vegetable protein, corn flakes/ breakfast cereals, pellets, aquatic feed/ pet food etc, it is enough to solve problems met during the production.

(2) Concept: Modular function, humanized system, diversified applications are always our pursuit. AHT Double Screw Extruder under the advanced design concept can meet various demands.

(3) Profession: Our professional manufacturing and processing would ensure the accuracy and coordination among each component of the extruder under the support of the stable processing and low noise.

(4) Precision: Precise food technology and material selection,which assure the working life of the extruder, minimizing the wear and tear of the screw and barrel.

(5) Experience: More than twenty years experience on the domestic and international advanced Double Screw Extruder. We have produced different kinds of extrusion food, like Vegetable protein, corn flakes/ breakfast cereals, pellets, aquatic feed/ pet food etc, it is enough to solve problems met during the production.

Model | Main Drive Power | Output |

AYT75 | 55KW | 1000KG/H |

AYT90 | 110KW | 1000~2000KG/H |

AYT100 | 160KW | 2000~4000KG/H |

AYT120 | 200KW/250KW | 4000~6000KG/H |

AYT135 | 280KW/315KW | 6000~8000KG/H |

Work Flow And Details Information

Work Flow

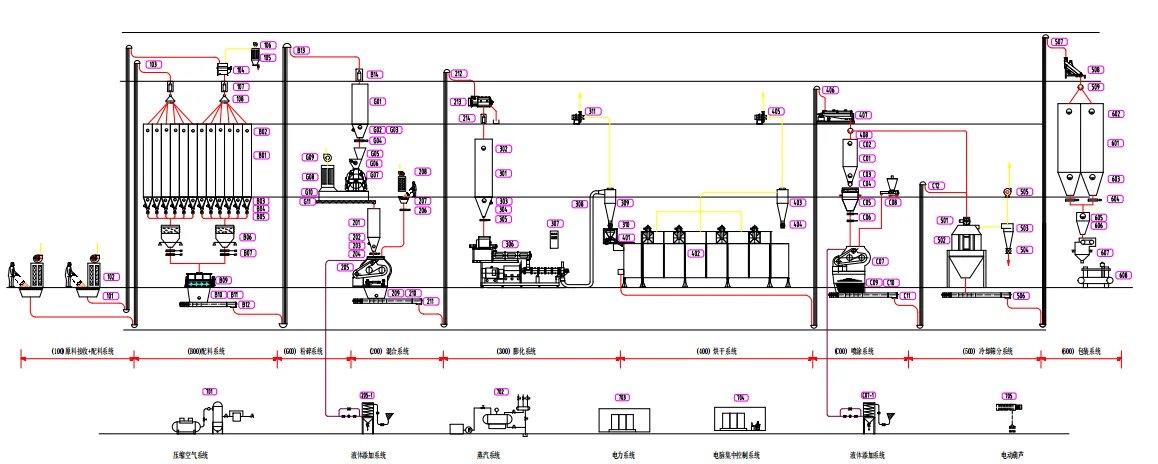

Flour Preparation → Crushing → Blending → Conditioning → Extruding → Drying → Coating → Cooling → Packing

Cross Circulation Efficient Oven

1, Cross circulation, side blowing, high drying efficiency, good insulation performance.

2, Separate dehumidification fan, the dehumidification speed is fast.

3, Box cargo type heat preservation door, easy to open, easy to clean, high temperature resistant silica gel sealing strip ensures good sealing performance.

4, Frequency conversion control, drying time adjustable. Output can be increased by adding additional section.

5, Upper heating box, steam heating, safe and reliable, upper heating box to avoid dust accumulation resulting in fire.

6, Equipped with automatic cleaning device, centralized collection of material slag, easy to clean.

2, Separate dehumidification fan, the dehumidification speed is fast.

3, Box cargo type heat preservation door, easy to open, easy to clean, high temperature resistant silica gel sealing strip ensures good sealing performance.

4, Frequency conversion control, drying time adjustable. Output can be increased by adding additional section.

5, Upper heating box, steam heating, safe and reliable, upper heating box to avoid dust accumulation resulting in fire.

6, Equipped with automatic cleaning device, centralized collection of material slag, easy to clean.

Full Automatic Batching System

1,The system consists of silo, weighing bucket and weighing control cabinet.The amount of silo depends on how many kinds of raw materials used.

2,The air hammer is installed under the silo wall to prevent the material from caking in the silo and affect the fluidity of the material.

3,the bottom of the silo tube is equipped with conveying winch, the winch motor is controlled by frequency converter, divided into high speed and low speed working state. High speed working condition is used for early rapid cutting. Low speed is applied to late slow blanking to ensure the accuracy of weighing.

4,The scale is controled by the microcomputer,the pressure sensor receives the pressure signal, converts the pressure signal into the electric signal, passes through the microcomputer processing, achieves the measurement, the weighing purpose.

5,The back of scale can be directly connected to mixing equipment such as mixing powder, high efficiency mixer, screw belt mixer and so on. If the customer workshop does not have enough height, can connect the conveying equipment such as screw conveyor, vacuum feeder, belt conveyor, etc.

3,the bottom of the silo tube is equipped with conveying winch, the winch motor is controlled by frequency converter, divided into high speed and low speed working state. High speed working condition is used for early rapid cutting. Low speed is applied to late slow blanking to ensure the accuracy of weighing.

4,The scale is controled by the microcomputer,the pressure sensor receives the pressure signal, converts the pressure signal into the electric signal, passes through the microcomputer processing, achieves the measurement, the weighing purpose.

5,The back of scale can be directly connected to mixing equipment such as mixing powder, high efficiency mixer, screw belt mixer and so on. If the customer workshop does not have enough height, can connect the conveying equipment such as screw conveyor, vacuum feeder, belt conveyor, etc.

High Efficiency Mixer

1, Mixing time is shortened to 1.5 minutes, in different mixing ratio,it can maintain mixing uniformity CV <5% with high output.

2, Low maintenance cost, wear blade can be removed and replaced at any time.

3, Rapid liquid addition, multiple spray, spray system.

4, High precision liquid quantitative addition system ensures the stability of the mixed finished product.

5, Mixer is easy to clean, operation safety is high.

6, The discharge port extends along the length of the whole tank to ensure that the mixed material can be completely discharged.

4, High precision liquid quantitative addition system ensures the stability of the mixed finished product.

5, Mixer is easy to clean, operation safety is high.

6, The discharge port extends along the length of the whole tank to ensure that the mixed material can be completely discharged.

Packing & Delivery

Company Profie

Our Company

(1) Provide variety models of twin-screw extruders and supporting ingredients, drying, tabling, baking, spraying, frying machines.

(2) Achieved equipment independe

(2) Achieved equipment independe

nt design and production, obtained a number of patents, successfully realized the grains products Extension and promotion of nutrition, rice, breakfast cereals, kinds of fried, non-fried snack foods, high molecular tissue proteins, brush tissue protein, instant porridge, instant rice and other fields.

(3) Provide complete food twin-screw extrusion technology engineering demonstration center, it can provide users with a multifunctional scientific research demonstration platform for food production equipment, technology, formula development and application, fully bridge the integration of production, learning and research, function, reduce the investment risk of customers, promote the application of extrusion technology in grain food processing and create value for customers.

(4) The scope of participation in food engineering projects includes the following: it enables us to provide our customers with a complete set of project solutions based on the specific requirement of our customers, and to propose, plan, design and project food plants to suit your budget and specific production needs.

(5) Complete turnkey system for crushing mixing systems, micro-component dosing systems, extrusion drying systems, and spray coating systems.

(6) Central centralized control system, whole plant automation engineering.

(7) Complete peripheral equipment: electrical installation, automation, pneumatic and liquid applications, civil engineering for turnkey projects.

(8) Application include breakfast cereal cornflakes, ready-to-eat rice nutrition rice series, protein, tissue protein, snack foods, pet food, aquatic feed, etc.

(3) Provide complete food twin-screw extrusion technology engineering demonstration center, it can provide users with a multifunctional scientific research demonstration platform for food production equipment, technology, formula development and application, fully bridge the integration of production, learning and research, function, reduce the investment risk of customers, promote the application of extrusion technology in grain food processing and create value for customers.

(4) The scope of participation in food engineering projects includes the following: it enables us to provide our customers with a complete set of project solutions based on the specific requirement of our customers, and to propose, plan, design and project food plants to suit your budget and specific production needs.

(5) Complete turnkey system for crushing mixing systems, micro-component dosing systems, extrusion drying systems, and spray coating systems.

(6) Central centralized control system, whole plant automation engineering.

(7) Complete peripheral equipment: electrical installation, automation, pneumatic and liquid applications, civil engineering for turnkey projects.

(8) Application include breakfast cereal cornflakes, ready-to-eat rice nutrition rice series, protein, tissue protein, snack foods, pet food, aquatic feed, etc.

Customer Case

Certifications

FAQ

(1) Q: What kind of production can be made?

A: Corn flakes, Puffs, Breakfast cereals food, Animal feed, Aquatic feed, Soya Texture protein food.

(2) Q: How is the delivery time?

A: Normally 40-45 days, depends on the final production and machine modification.

(3) Q: How about the installation service?

A: Depend on the whole line equipment list, normally needs 2-3 weeks. Will provide the installation service, like start, operating, inspection machines, testing different formulations.

(4) Q: How is the warranty time?

A:1 Year, for the screw and barrel, due to they are adopted modular design, change the wear part will be ok, unlike the complete set screw, no need change whole set.

A: Corn flakes, Puffs, Breakfast cereals food, Animal feed, Aquatic feed, Soya Texture protein food.

(2) Q: How is the delivery time?

A: Normally 40-45 days, depends on the final production and machine modification.

(3) Q: How about the installation service?

A: Depend on the whole line equipment list, normally needs 2-3 weeks. Will provide the installation service, like start, operating, inspection machines, testing different formulations.

(4) Q: How is the warranty time?

A:1 Year, for the screw and barrel, due to they are adopted modular design, change the wear part will be ok, unlike the complete set screw, no need change whole set.