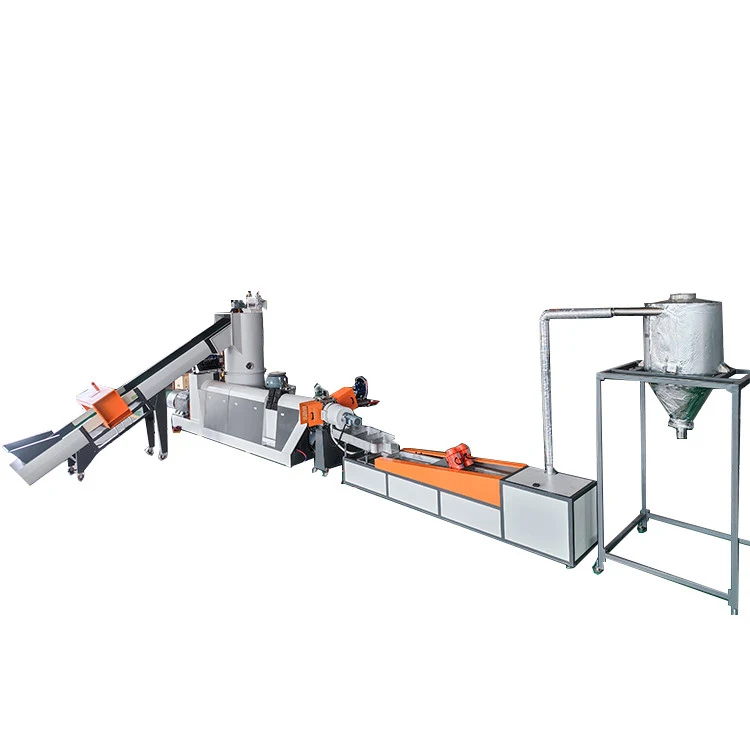

Китайский завод продавец гранулятор пластик Ldpe ПВХ линия гранулирования горячей

- Категория: Plastic Raw Material Machinery >>>

- Поставщик: Zhangjiagang,Weiquan,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 88060.34 $* | 92463.77 $* |

| Aug-16-2025 | 87320.28 $* | 91686.23 $* |

| Jul-16-2025 | 73260.20 $* | 76923.43 $* |

| Jun-16-2025 | 85840.97 $* | 90132.46 $* |

| May-16-2025 | 74740.76 $* | 78477.21 $* |

| Apr-16-2025 | 84360.61 $* | 88578.9 $* |

| Mar-16-2025 | 83620.0 $* | 87801.10 $* |

| Feb-16-2025 | 82880.2 $* | 87024.46 $* |

| Jan-16-2025 | 82140.3 $* | 86247.10 $* |

Характеристики

BOPP LLDPE HDPE LDPE PE PP recycling granulating machine is special equipment for the plastic film/bags recycling granulating, it equipped with compacting machine which pre-compact the film into smaller granules, then easily feed into screw barrel of extruder, its efficiency is high and can improve production capacity

it has vacuum exhausting system on extruder barrel which can fully vent the moisture in the material and hence the final granule quality will be very perfect.

end of screw barrel, it equipped with double station fast speed hydraulic non -stop screen changer which can efficiently filter out the dirty in the plastic melt.

the pelletizing adopts water cooling pelletizing which is easier to operate, and the shape and appearance of granule is good.

Force compactor machine

First Stage (mother stage)

Double position board model,non-stop change screen Board made by 38CrMnAl with forging, heating treatment won’t deform after heating using. Screen changing driven by hydraulic

Installed on the first Extruder Made by 40Cr material with tempering and quenching treatment Heating up by the heating core Design as a material disperser so the material comes out as noddle, so it can remove the air and humidity from the material

Extruder barrel made by sturdy frame, heavy. No vibrating when machine running; the whole frame where installed the gearbox, motor and screw has done the milling working. Use 38CrMnAlA making screw, nitriding treatment which can used for long lifetime.

Vertical die head cutter

S Model cooling tank + vertical dewatering machine + vibrator machine

Big volume storage silo made by Stainless steel

Zhangjiagang WeiQuan Machinery Co., Ltd. is located in the Zhangjiagang City, which in the Shanghai economic circle. Our company specializes producing plastic recycling and extrusion machinery.

The recycling part includes but is not limited to PE/PP/PET waste plastic crushing, washing and granulating machines, and also auxiliary machines.

The extrusion part includes but is not limited to PVC/PE/PPR pipe machine, PVC/PE/WPC profile machine and also auxiliary machines.

We have our own R&D team and factory. All equipment is constantly updated to meet customer requirements. The equipment is exported to more than 100 countries and regions overseas and is well received by users. We uphold all the tenet of setting up factories based on the interests of customers, treat people honestly, make machines seriously, serve every customer with heart, support customers' various tasks, and achieve a win-win situation is our ultimate goal.

Q1: Are you a factory or trading company?

A1: We are a factory and can provide customized services.

Q2: What services will you provide?

A2:

We will provide all the machines for the complete production according to customer's requirements.

We will provide complete service for factory layout and other information to help customer to build the factory.

We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

Except one year quality guarantee, we will provide after-sell service for all the life.

Q3: What can i buy from you?

A3: Plastic crusher, Plastic Washing Recycling Line, Plastic Pelletizing Recycling Line, Pet Bottle Recycling Line, Plastic Squeezing Machine, Plastic Pipe/ Profile Extrusion Line...etc. We are a factory and can provide customized services.

Q4: Why should i buy from you not from other suppliers?

A4: We have more than 10 years experience in fabricating the machine, we can fabricating the machine according to customer request.

Q5: What basic terms can you accept?

A5: Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency: USD,EUR,CNY;

Accepted Payment Type: T/T,L/C.