Заводская поставка 100000 химическое сырье с вязкостью гидроксипропил метилцеллюлоза

- Категория: Paper Chemicals >>>

- Поставщик: Jinzhou,Tujin,Building,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 4058.42 $* | 4139.32 $* |

| Jul-16-2025 | 3291.95 $* | 3357.77 $* |

| Jun-16-2025 | 3994.67 $* | 4074.86 $* |

| May-16-2025 | 3962.58 $* | 4041.1 $* |

| Apr-16-2025 | 3163.7 $* | 3226.47 $* |

| Mar-16-2025 | 3898.29 $* | 3976.16 $* |

| Feb-16-2025 | 3866.4 $* | 3943.79 $* |

| Jan-16-2025 | 3834.51 $* | 3911.62 $* |

Характеристики

Specification

item | value |

Classification | Chemical Auxiliary Agent |

CAS No. | 9004-65-3 |

Other Names | Hydroxypropyl methyl cellulose |

Place of Origin | China |

Hebei | |

Type | disinfectant |

Usage | Water Treatment Chemicals |

Model Number | Hydroxypropyl methyl cellulose |

Product name | hpmc putty powder mortar |

CAS | 9004-65-3 |

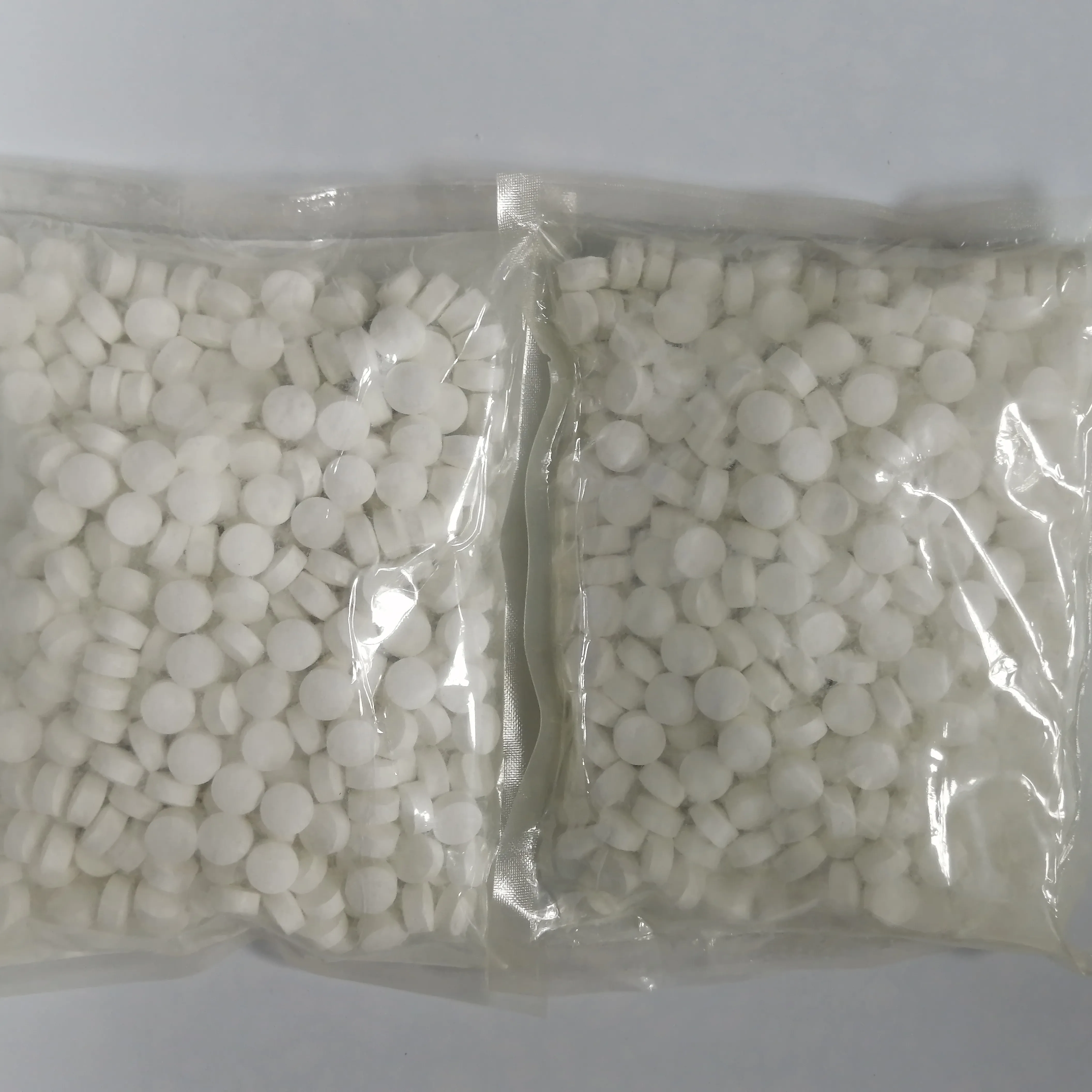

color | milk white |

size | 58*95 |

material | plastic |

Hydroxypropyl methyl cellulose

Hypropyl methylcellulose (hypropyl mellose), also known as hydroxypropyl methylcellulose, is a kind of non-ionic cellulose mixed ether.

Appearance: white or white like fibrous or granular powder

Use: as thickener, dispersant, binder, extrander, oil resistant coating, filler, emulsifier and stabilizer in textile industry. Also widely used in synthetic resin, petrochemical, ceramics, paper, leather, medicine, food and cosmetics and other industries.

Main uses:

1, construction: as a water retaining agent of cement mortar, retarding agent to make mortar pumping. In the spread of mortar,lime, putty powder or other building materials as a binder, improve the spread and extend the operating time. Used as adhesive ceramic tile, marble, plastic decoration adhesive reinforcing agent, can also reduce the amount of cement. HPMC water retention properties so that the slurry after daub will not dry too fast and crack, enhance the strength of hardening.

2, ceramic manufacturing industry: widely used as adhesive in the manufacturing of ceramic products.

3, coating industry: in the coating industry as a thickener, dispersant and stabilizer, in water or organic solvents have good compatibility, as paint remover.

4, ink printing: in the ink industry as a thickener, dispersant and stabilizer, in water or organic solvents have good compatibility.

5, plastic: forming release agent, softener, lubricant, etc.

6, PVC: PVC production as dispersant, suspension polymerization preparation of PVC main additives.

7, pharmaceutical industry: coating materials; Membrane material; Rate-controlling polymer materials for sustained-release preparations; Stabilizing agent; Suspended aid; Tablet adhesive; tackifier

8, others: also widely used in leather, paper products industry, fruit and vegetable preservation and textile industry.

Dissolution method

1. All models can be added to the material by dry mixing method.

2, need to be directly added to the normal temperature aqueous solution, the best use of cold water dispersal type, after adding generally in 10-90 minutes to thicken.

3, ordinary model first with hot water stir dispersion, add cold water stir cooling can be dissolved.

4. If the phenomenon of agglomeration occurs when dissolving, it is because the stirring is not sufficient or the ordinary model is directly added to the cold water. At this time, it should be stirred quickly.

5. If bubbles are generated during dissolution, they can be removed by standing for 2-12 hours (the specific time depends on the consistency of the solution) or by means of vacuum pumping and pressure, or by adding an appropriate amount of defoaming agent.

Hypropyl methylcellulose (hypropyl mellose), also known as hydroxypropyl methylcellulose, is a kind of non-ionic cellulose mixed ether.

Appearance: white or white like fibrous or granular powder

Use: as thickener, dispersant, binder, extrander, oil resistant coating, filler, emulsifier and stabilizer in textile industry. Also widely used in synthetic resin, petrochemical, ceramics, paper, leather, medicine, food and cosmetics and other industries.

Main uses:

1, construction: as a water retaining agent of cement mortar, retarding agent to make mortar pumping. In the spread of mortar,lime, putty powder or other building materials as a binder, improve the spread and extend the operating time. Used as adhesive ceramic tile, marble, plastic decoration adhesive reinforcing agent, can also reduce the amount of cement. HPMC water retention properties so that the slurry after daub will not dry too fast and crack, enhance the strength of hardening.

2, ceramic manufacturing industry: widely used as adhesive in the manufacturing of ceramic products.

3, coating industry: in the coating industry as a thickener, dispersant and stabilizer, in water or organic solvents have good compatibility, as paint remover.

4, ink printing: in the ink industry as a thickener, dispersant and stabilizer, in water or organic solvents have good compatibility.

5, plastic: forming release agent, softener, lubricant, etc.

6, PVC: PVC production as dispersant, suspension polymerization preparation of PVC main additives.

7, pharmaceutical industry: coating materials; Membrane material; Rate-controlling polymer materials for sustained-release preparations; Stabilizing agent; Suspended aid; Tablet adhesive; tackifier

8, others: also widely used in leather, paper products industry, fruit and vegetable preservation and textile industry.

Dissolution method

1. All models can be added to the material by dry mixing method.

2, need to be directly added to the normal temperature aqueous solution, the best use of cold water dispersal type, after adding generally in 10-90 minutes to thicken.

3, ordinary model first with hot water stir dispersion, add cold water stir cooling can be dissolved.

4. If the phenomenon of agglomeration occurs when dissolving, it is because the stirring is not sufficient or the ordinary model is directly added to the cold water. At this time, it should be stirred quickly.

5. If bubbles are generated during dissolution, they can be removed by standing for 2-12 hours (the specific time depends on the consistency of the solution) or by means of vacuum pumping and pressure, or by adding an appropriate amount of defoaming agent.

Product Description

Packing & Delivery

Company Profile

Tujin in Jinzhou, Hebei Province is a technical and professional company integrating science, industry and trade. The factory is located in Jinzhou City, Hebei Province, China, 260 kilometers away from the capital Beijing. It is crisscrossed by high-speed railways,highways and national roads. It is close to Tianjin port and Qingdao port. The transportation is very convenient and can provide customers with faster and better services in time.

Tujin in Jinzhou, Hebei Province covers an area of 120000 square meters and a construction area of 80000 square meters. It has advanced automatic production line and world-class production equipment. At present, the products mainly include redispersible latex powder (rdp-vae), polypropylene crack resistant staple fibers, polyvinyl alcohol (PVA), titanium dioxide, and other cellulose (HPMC, MHEC, HEC, CMC), with an annual production of more than 30000 tons.

The company has strong technical force, a large number of professional and technical personnel, R & D personnel and rich production experience. The factory laboratory and laboratory have complete testing equipment and perfect testing means. The product raw materials are carefully selected, and the leaders of the company visit the front line to check the production process at all levels, which has laid a foundation for product quality.

The product quality is synchronized with international standards, and the sales scope covers all parts of China and exported abroad.

Hebei Jinzhou Tujin will always pursue the goal of quality first and service first, uphold the concept of integrity-based and excellence, constantly explore and innovate, increase product types, and provide more and better products for customers at home and abroad.

We sincerely hope to cooperate and develop with new and old customers at home and abroad to create a brilliant tomorrow!

Tujin in Jinzhou, Hebei Province covers an area of 120000 square meters and a construction area of 80000 square meters. It has advanced automatic production line and world-class production equipment. At present, the products mainly include redispersible latex powder (rdp-vae), polypropylene crack resistant staple fibers, polyvinyl alcohol (PVA), titanium dioxide, and other cellulose (HPMC, MHEC, HEC, CMC), with an annual production of more than 30000 tons.

The company has strong technical force, a large number of professional and technical personnel, R & D personnel and rich production experience. The factory laboratory and laboratory have complete testing equipment and perfect testing means. The product raw materials are carefully selected, and the leaders of the company visit the front line to check the production process at all levels, which has laid a foundation for product quality.

The product quality is synchronized with international standards, and the sales scope covers all parts of China and exported abroad.

Hebei Jinzhou Tujin will always pursue the goal of quality first and service first, uphold the concept of integrity-based and excellence, constantly explore and innovate, increase product types, and provide more and better products for customers at home and abroad.

We sincerely hope to cooperate and develop with new and old customers at home and abroad to create a brilliant tomorrow!

FAQ

1.What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3.Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

5.How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6.what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A : We consider honest as the life of our company, we can tell you the contact information of our some other clients for you to check our credit. Besides, there is trade assurance from Alibaba, your order and money will be well guaranteed.

3.Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4.Where are you? Can I visit you?

A: Sure,welcome to you visit our factory at any time.

5.How about the delivery time?

A: Within 15-35 days after we confirm you requirement.

6.what kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash, Western Union are all accepted if you have other payment,please contact me.