Автоматическое оборудование для смешивания сухого раствора 10

- Категория: Dry Mortar Machines >>>

- Поставщик: Zhengzhou,Unique,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.93 $* | 0.80 $* |

| Aug-19-2025 | 0.18 $* | 0.15 $* |

| Jul-19-2025 | 0.96 $* | 0.89 $* |

| Jun-19-2025 | 0.16 $* | 0.21 $* |

| May-19-2025 | 0.30 $* | 0.13 $* |

| Apr-19-2025 | 0.67 $* | 0.52 $* |

| Mar-19-2025 | 0.51 $* | 0.45 $* |

| Feb-19-2025 | 0.3 $* | 0.71 $* |

| Jan-19-2025 | 0.48 $* | 0.16 $* |

Характеристики

1. Parameter

| Model | TZS5 | TZS10 | TZS15 | TZS20 | TZS30 | note |

| theory production(t/h) | 10-20 | 20-40 | 40-60 | 60-80 | 80-120 | |

| host model | SHH-2 | SHH-4 | SHH-6 | SHH-8 | SHH-10 | |

| power(kw) | 18.5 | 22 | 30 | 45 | 55 | |

| Plot ratio | 60% | 60% | 60% | 60% | 60% | |

| aggregate size | 4.75 | 4.75 | 4.75 | 4.75 | 4.75 | |

| Sand scale(kg) | (200-1300)±1% | (200-2000)±1% | (400-3000)±1% | (400-3800)±1% | (500-5800)±1% | customizable |

| Cement scale(kg) | (100-700)±1% | (100-800)±1% | (200-1300)±1% | (200-1800)±1% | (200-2000)±1% | |

| Additive scale(kg) | (5-30)±0.5% | (10-50)±0.5% | (10-200)±0.5% | (10-200)±0.5% | (10-200)±0.5% | customizable |

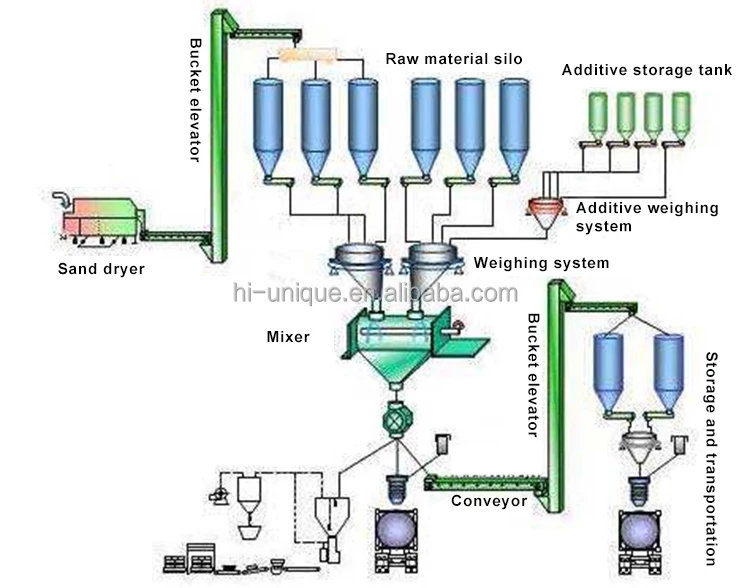

2. Equipment composition

3. characteristics

01. Drying system

Mixing console USES three return tumble dryer, discharge temperature of 65 ℃ or less and the moisture content < 0.5%; Years of sand dryer manufacturing experience, efficient drying system energy - saving

02. Measurement system

Accurate, stable and reliable feeding technology, accurate and correct, ensure the operation of production line reliability, ensure product quality

03. Stirring machine

The new generation of two-axis gravity-free mixer, reasonable body design, high efficiency skills, with the core technology of tripod machinery, durable and durable

04. Dust removal system

Personalized dust removal system ensures no dust pollution in working environment

05. Bulk system

We can design the bulk system of direct discharging and the bulk system with pre-storage effect according to the customer's requirement, so as to meet the customer's requirement to the greatest extent

06. Control system

Adopt the control system of high quality electric element, stable and efficient

07. Bag system

The bag system with unique design higher than the industry quality standard is convenient for the packaging production of special mortar

08. Conveying system

Reliable transport system, wear - resistant stability, low fault rate

09. Supporting scheme

Automatic packaging and stacking system is designed

Special mortar production line non - standard customization

UNIQUE Group was founded in 1983, which has been dedicated to making the most suitable products and services for construction enterprises for more than 30 years, focused on providing comprehensive solutions for engineering construction, expanding the field, healthy development, built mainly with development and production of construction machinery, across regions, and cross-industry conglomerates.

For 40 years, UNQIUE Group relied on scientific and technological innovation, optimize the structure of products. Concrete machinery products are currently JZC series, JS series concrete mixer, PLD concrete batching machine, HZS series concrete mixing plant, mobile concrete mixing plant, WBZ-series stabilized soil mixing plant, planetary concrete mixers and so on concrete mixing machinery.

UNIQUE Group wholeheartedly serves concrete machinery industry at home and abroad, provides high quality products, fast after-sales service, and goes to a better future with you hand in hand!

Our Workshop:

Pre-sale Service:

24 hours online; CE, ISO Certification available.

More than 30 years experience in construction platform industry.

Customized service is available, including capacity, productivity, color, design, depend on your idea!

After-sales Service:

Training how to install and use the machine;

Engineers avilable to service machinery overseas;

Sufficient spear parts in stock provide for equipment whole life.

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: Do you have CE certificate for your concrete batching plant / dry mortar production line?

A: Yes, we have. Both are our patent products, certificated by CE.