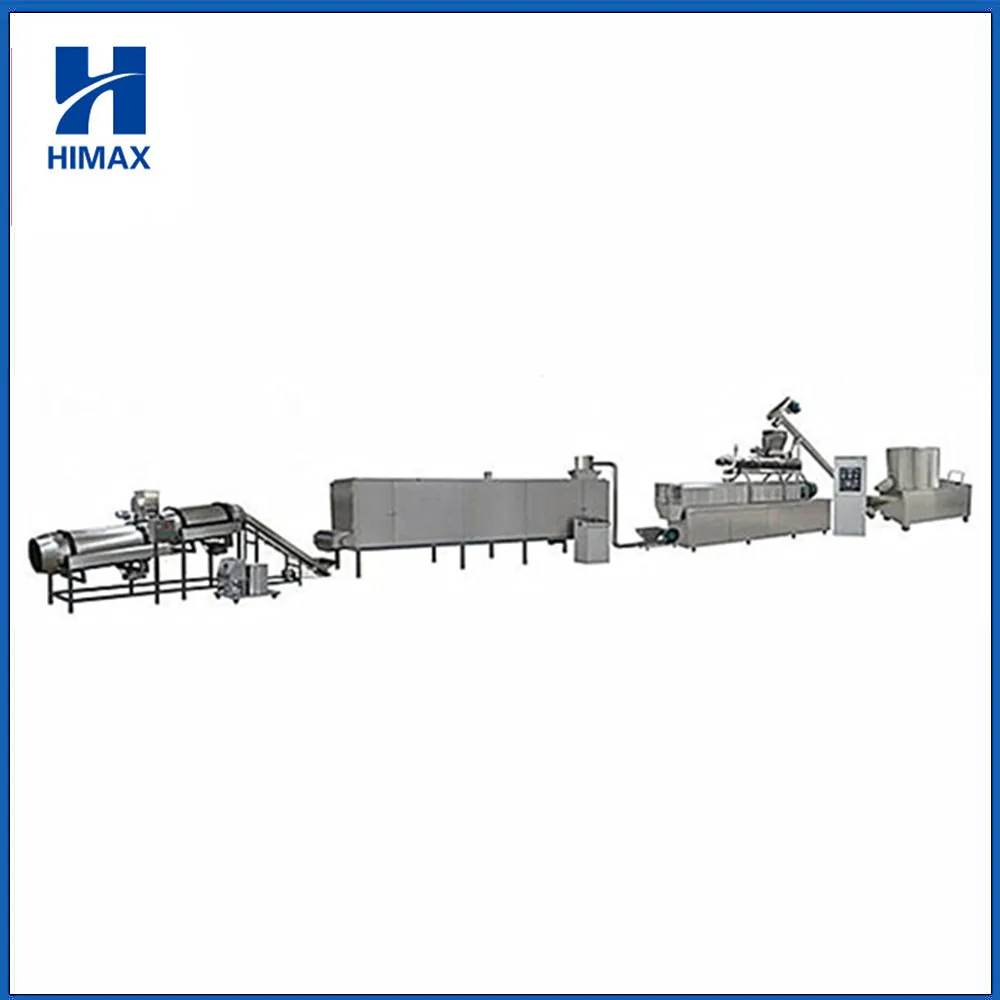

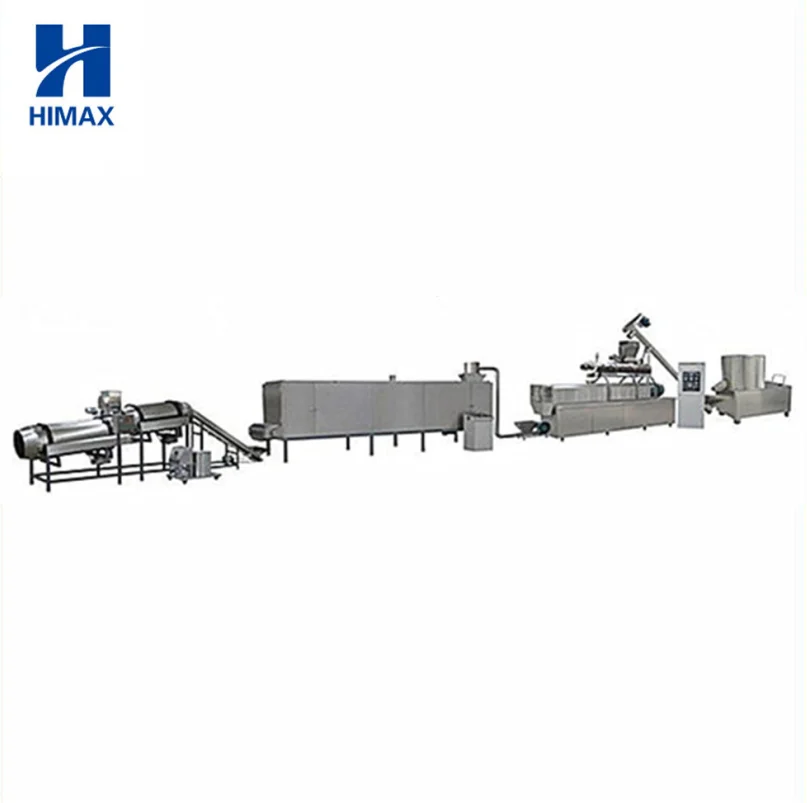

Полностью автоматическая линия по производству корма для собак машина

- Категория: Feed Processing Machines >>>

- Поставщик: Jinan,Himax,Machinery,Co.,Ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 14280.84 $* | 14994.48 $* |

| Aug-19-2025 | 14160.11 $* | 14868.48 $* |

| Jul-19-2025 | 11880.11 $* | 12474.32 $* |

| Jun-19-2025 | 13920.95 $* | 14616.47 $* |

| May-19-2025 | 12120.75 $* | 12726.41 $* |

| Apr-19-2025 | 13680.54 $* | 14364.21 $* |

| Mar-19-2025 | 13560.88 $* | 14238.90 $* |

| Feb-19-2025 | 13440.96 $* | 14112.67 $* |

| Jan-19-2025 | 13320.86 $* | 13986.37 $* |

Характеристики

Best sell dog Feed Making production line

dog food processing Machine

dog feed bulking machines

Pet food and aquatic feed is close to the human beings food in the fine level, the health index and the nutritional ingredients, some of them request more highly than beings. Pet food and aquatic feed generally consists of meat, meat by products, cereal, grain, vitamins, and minerals. General grains, such as soybean meal, corn meal, cracked wheat, and barely, are often used to improve the consistency of the products. The meat is mixed with the other ingredients. Our product line can produce dog food, cat food, fish food, bird food, monkey food and so on,

Flow Chart

Mixer-->Twin-screw extruder-->Air conveyor-->Dryer-->Hoister-->Flavoring machine-->Hoister-->Cooler

Raw material

Wheat flour,Corn flour,Protein food,Meat products,Soya Bean and so on.

PARAMETER INTERPRETATION

Material | Install Power (kw) | Real Power (kw) | Capacity (kg per hour) |

Corn flour, rice powder,shrimp meal etc. | 89.18 | 80 | 200-250 |

Size of the line (m) | Size of workshop (m^2) | Staff (people) | Delivery (days) |

30 x 4 x 5 | 120 | 1 - 2 | 30 days |

SAMPLE

PRODUCT DETAILS

mixer

mixer makes the raw material adding to water and liquid chemical additive fully mixed

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Features:

1.This part that touches mixer to material adopts the stainless steel material.

2. The discharge hole adopts the new handle-opened design. It has the good seal so that the materials.

Screw Conveyor

The mixed materials can be conveyed in the stainless steel roller to the feeding machine (feeder) of extruder without any leaking,

dusting and pollution; Feed quantity and speed is even and stable.

dusting and pollution; Feed quantity and speed is even and stable.

Extruder bulking machine

The twin -screw extruder is made of the feeding system, extruding system, cutting system, heating system, conditioner and

controlling system.

1. The screws are made of the alloy steel;

2. The forced lubrication system ;

3. Auto-temperature control system;

4, Auto-speed control system

5. Self-cleaning.

6.With the bearing is NSK which made from japan.

controlling system.

1. The screws are made of the alloy steel;

2. The forced lubrication system ;

3. Auto-temperature control system;

4, Auto-speed control system

5. Self-cleaning.

6.With the bearing is NSK which made from japan.

Air Conveyor

1. Air conveyor conveys the food relying on the wind-force from the blower.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

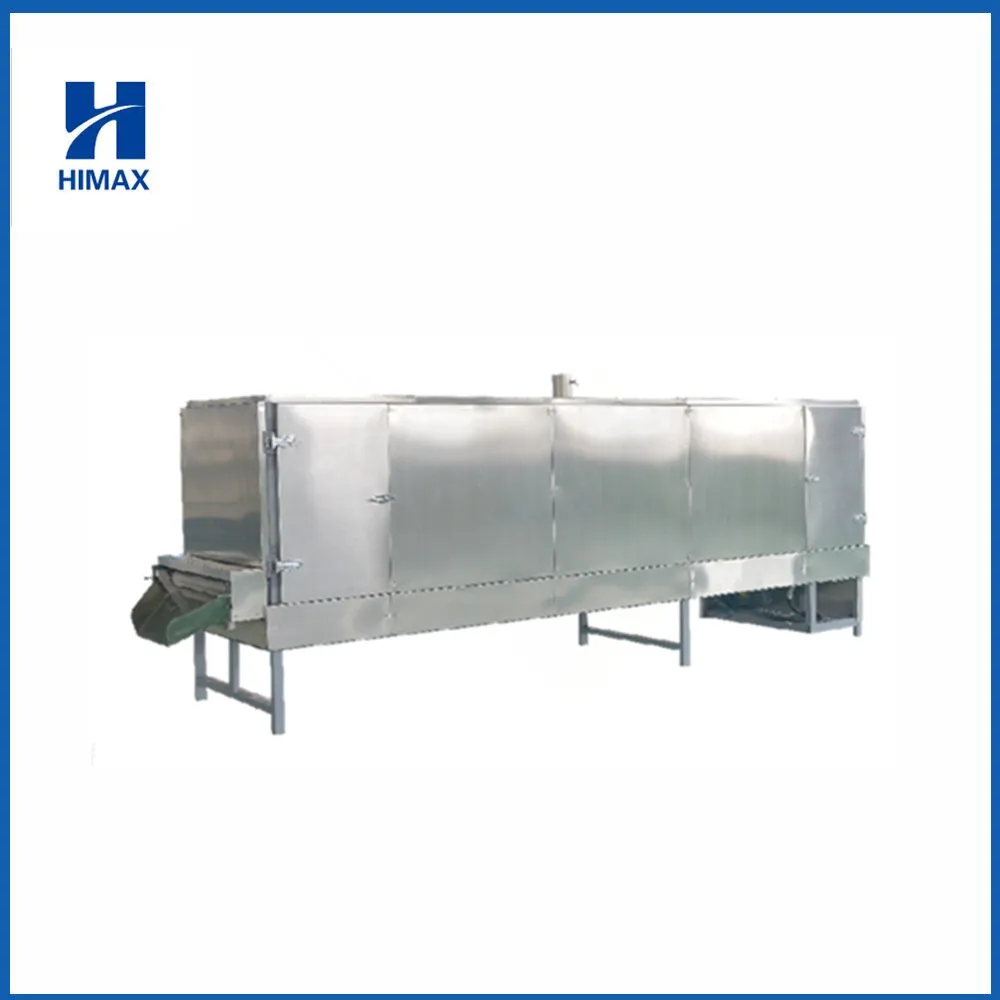

Dryer

The heating way is gas/furel oil heating.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

The net belt running speed can be controlled to change the food drying time in the dryer.

The temperature also can be controlled.

Multi-layer dryer is with compact size than other type dryers.

Hoister.

Hoister conveys the food from the low to high, according to the craft; decide the hoister height and the level distance.

Hoister can be classified into big and small according to the hoister height and the level distance.

Hoister can be classified into big and small according to the hoister height and the level distance.

Rollers with flavor

The stainless steel flavor feeder is used to spray powder flavor to the drum. We can control the spraying quantity via the

different speed which controlled by the soft start.

With the two drums, the food can be flavored well.

different speed which controlled by the soft start.

With the two drums, the food can be flavored well.

Air conveyor

1. Air conveyor conveys the food relying on the wind-force from the blower.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

2. Low energy-consumption, high efficiency.

3. It has not the features of leaking material and pollution when the food is conveyed in the sealed stainless steel pipeline.

Automatic plastic Packing machine

Dimension(m): 2.5×0.8×2.8

Power: 2.7KW

Weight:350KG

Packing speed: 5-8 bags/min

Weight range:5-20kg/bag

Function:

Pack food. Seal the plastic bag.

Can pack from 5kg to 25kg per bag

Power: 2.7KW

Weight:350KG

Packing speed: 5-8 bags/min

Weight range:5-20kg/bag

Function:

Pack food. Seal the plastic bag.

Can pack from 5kg to 25kg per bag

PRODUCTION REAL SHOT

BUYER EVALUATION

PACKING&SHIPPING

ABOUT US

Jinan Himax Machinery Co., Ltd. is a professional supplier of food processing machines.We offer our customers for mutual and

beneficial development. All Inquiries are welcome. We have many kinds of machines and production line, such as food extrusion

machine, soya meat production line, industrial microwave oven, packaging machine, pet food production.importantly, we also provide

formulas, technology supports, machine inspection service, etc. Cooperating with different manufacturers and research centers, we

provide the food processing machines with outstanding quality. We have a group of experienced experts and outstanding engineers

who do provide the professional service ,delivery and installation. Based on the clients specific requirement, we also OEM

machines for each clients. We have through the years established good working relationship with some reputable organizations both

at home and abroad with outstanding goodwill. Whatever food processing machine you need from China, please contact with Jinan

Himax Machinery Co.,Ltd.

beneficial development. All Inquiries are welcome. We have many kinds of machines and production line, such as food extrusion

machine, soya meat production line, industrial microwave oven, packaging machine, pet food production.importantly, we also provide

formulas, technology supports, machine inspection service, etc. Cooperating with different manufacturers and research centers, we

provide the food processing machines with outstanding quality. We have a group of experienced experts and outstanding engineers

who do provide the professional service ,delivery and installation. Based on the clients specific requirement, we also OEM

machines for each clients. We have through the years established good working relationship with some reputable organizations both

at home and abroad with outstanding goodwill. Whatever food processing machine you need from China, please contact with Jinan

Himax Machinery Co.,Ltd.

PRODUCT CERTIFICATE

F&Q

1. Q:What is your delivery time?

30 days after downpayment.We have our own forwarder and we have long term cooperation with each other and have closely

relationship with each other,so there is no problem.

2. Q:Payment Way?

L/C and T/T or other ways.

3.Q:What's the shipping way?

According to YOUR demands to decide ship by sea or air4.Q:Can you accept OEM or ODM?

Yes, of course. logo is also acceptable. ODM is also welcome

5.Q:How is Warranty?

1)One years guarantee from the delivery date of this machine under the normal operation of one shift per day!

2)We will be responsible for maintenance of damaged part which is under normal situation during warranty period,and all the

round-trip courier transportation cost of damaged /repaired replacement parts in warranty period should be borne by the

buyer.Wearing parts are not included.

3)24 hour technical support by email or calling.

4)User-friendly English manual for machine using and maintaining.

6.Our service?

1)One-stop service,meet needs of the customers from individuals to international companies.

2)Separate trading office:Himax machinery with 14 years experienced sales offering full scale service.

3)After sale service:experienced and knowledgeable team of technical support,provide engineer oversea service.

30 days after downpayment.We have our own forwarder and we have long term cooperation with each other and have closely

relationship with each other,so there is no problem.

2. Q:Payment Way?

L/C and T/T or other ways.

3.Q:What's the shipping way?

According to YOUR demands to decide ship by sea or air4.Q:Can you accept OEM or ODM?

Yes, of course. logo is also acceptable. ODM is also welcome

5.Q:How is Warranty?

1)One years guarantee from the delivery date of this machine under the normal operation of one shift per day!

2)We will be responsible for maintenance of damaged part which is under normal situation during warranty period,and all the

round-trip courier transportation cost of damaged /repaired replacement parts in warranty period should be borne by the

buyer.Wearing parts are not included.

3)24 hour technical support by email or calling.

4)User-friendly English manual for machine using and maintaining.

6.Our service?

1)One-stop service,meet needs of the customers from individuals to international companies.

2)Separate trading office:Himax machinery with 14 years experienced sales offering full scale service.

3)After sale service:experienced and knowledgeable team of technical support,provide engineer oversea service.