GLWA-120 провода сокращения прокатки

- Категория: Rolling Mill >>>

- Поставщик: Zhangjiagang,Dawn,Machinery,Technology,Co.,ltd

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.37 $* | 0.7 $* |

| Aug-17-2025 | 0.92 $* | 0.21 $* |

| Jul-17-2025 | 0.43 $* | 0.80 $* |

| Jun-17-2025 | 0.34 $* | 0.50 $* |

| May-17-2025 | 0.63 $* | 0.53 $* |

| Apr-17-2025 | 0.78 $* | 0.12 $* |

| Mar-17-2025 | 0.33 $* | 0.95 $* |

| Feb-17-2025 | 0.22 $* | 0.84 $* |

| Jan-17-2025 | 0.40 $* | 0.61 $* |

Характеристики

Product Description

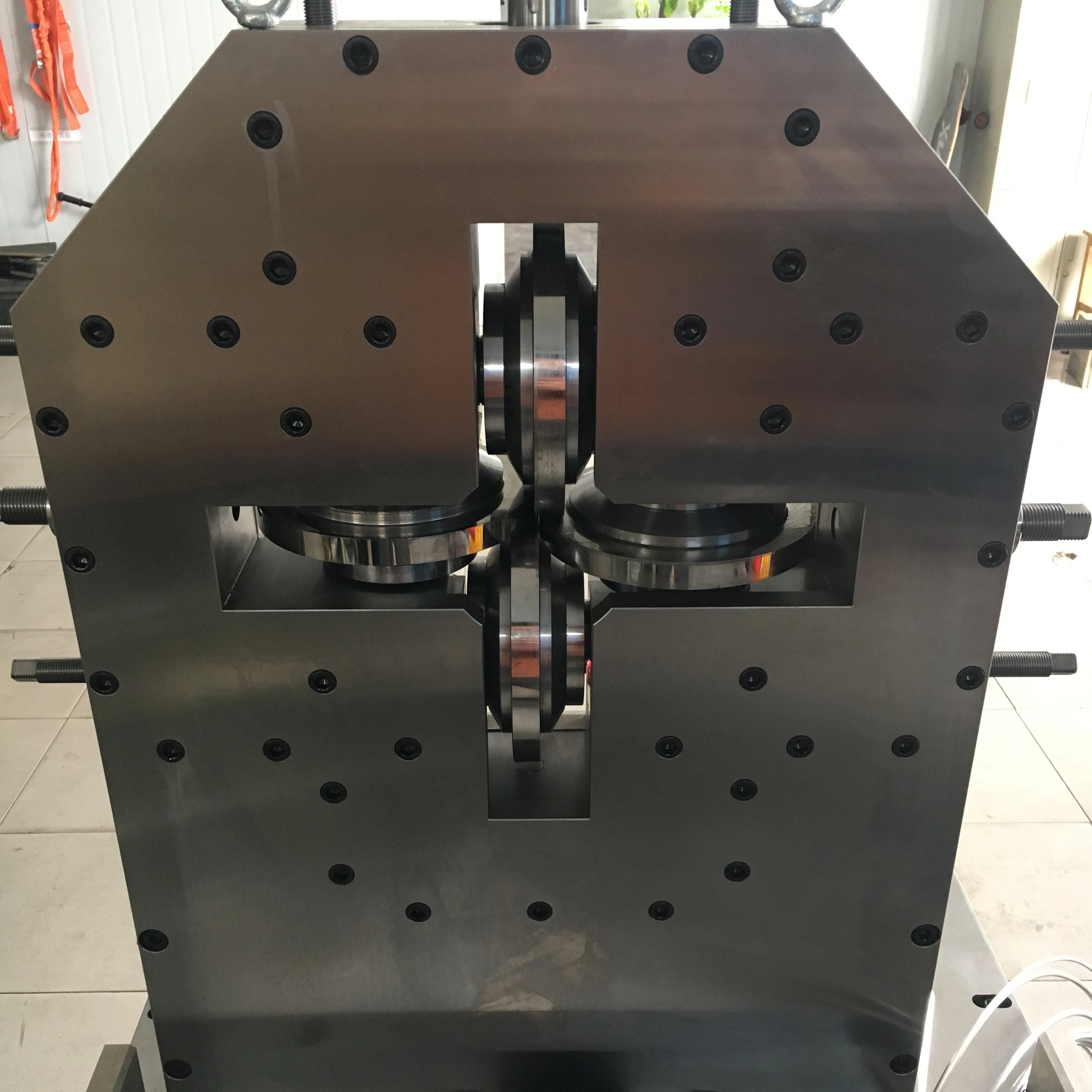

C-type driven rolling cassette, Y-type non-drive rolling cassette

It is the rolling type dies, the main purpose of the cold rolling cassette: is to replace the wire drawing die, for the low carbon steel wire titanium alloy wire drawing reducing die.

introduction: After the roller die / Cold rolling cassette replaces the wire drawing die, the allowable wire drawing machine speed is increased within the allowable range of the machine and equipment, the alloy composition of the finished steel wire is more symmetrical, and the wire quality is improved. -Some products can reduce the quenching by drawing several times. Frequent or withdraw quenching; in addition, rolling instead of drawing, less energy consumption, less friction, and stronger surface cleaning

Structure: The cassette roller die is composed of rollers and rolling bearings, shafts, roll mold support frames and related sealing connectors. The selection of correct roller die is based on the raw materials and the different wire diameters.

Advantages

Compared with wire drawing dies, the significant advantages depend on:

1.Improve production capacity or equipment utilization: reduce the time for shutting down and changing molds, reduce the disconnection rate, allow the wire drawing machine to accelerate, and improve the production capacity of machinery and equipment;

2.Improve the quality of the group outlet: the group outlet axial mechanism is well-proportioned, the physical performance is improved, there is no moisturizing powder surface, and the cleanability is improved;

3-Environmental protection and energy saving, saving manpower, some raw materials can reduce the number of quenching passes and reduce the cycle time of production and processing;

4-Improve the natural environment: reduce the application of wire drawing powder, and the natural environment of the production workshop is tidy.

Applying materials: suitable for ferrous metals, such as high-carbon, medium-carbon, low-carbon steel wire, stainless steel wire, titanium wire, titanium nickel alloy wire.

Attribute: 2 options, Non drives and driven

Advantages: CRM has an experience team of highly qualified and strongly motivated people that develops turks head dies for the rolling wire industry.

It can be operated without lubricating oil (dry operation) in a special case,

Different from the drawing die with “one model one die” it possible of roller non-replacing when forming flat and shaped wires.

Roll material: carbide.

Roll diameter: 75-150mm

Equipment quality inspection

In order to ensure the quality of metal parts, conform to the product Production demand. We carry out Measure, inspect, test and measure, and conclude Compare the results with the specified requirements, and determine Each feature is qualified, and strive for high quality, High-precision cold rolling mills are provided to customers.