Машина для переработки пластиковых ПЭТ бутылок BOXIN

- Категория: Recycle Washing Line >>>

- Поставщик: Zhangjiagang,Boxin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 148750.46 $* | 156188.57 $* |

| Aug-19-2025 | 147500.96 $* | 154875.48 $* |

| Jul-19-2025 | 123750.38 $* | 129938.14 $* |

| Jun-19-2025 | 145000.56 $* | 152250.3 $* |

| May-19-2025 | 126250.86 $* | 132563.89 $* |

| Apr-19-2025 | 142500.43 $* | 149625.31 $* |

| Mar-19-2025 | 141250.51 $* | 148313.12 $* |

| Feb-19-2025 | 140000.45 $* | 147000.92 $* |

| Jan-19-2025 | 138750.37 $* | 145688.50 $* |

Характеристики

Product Description

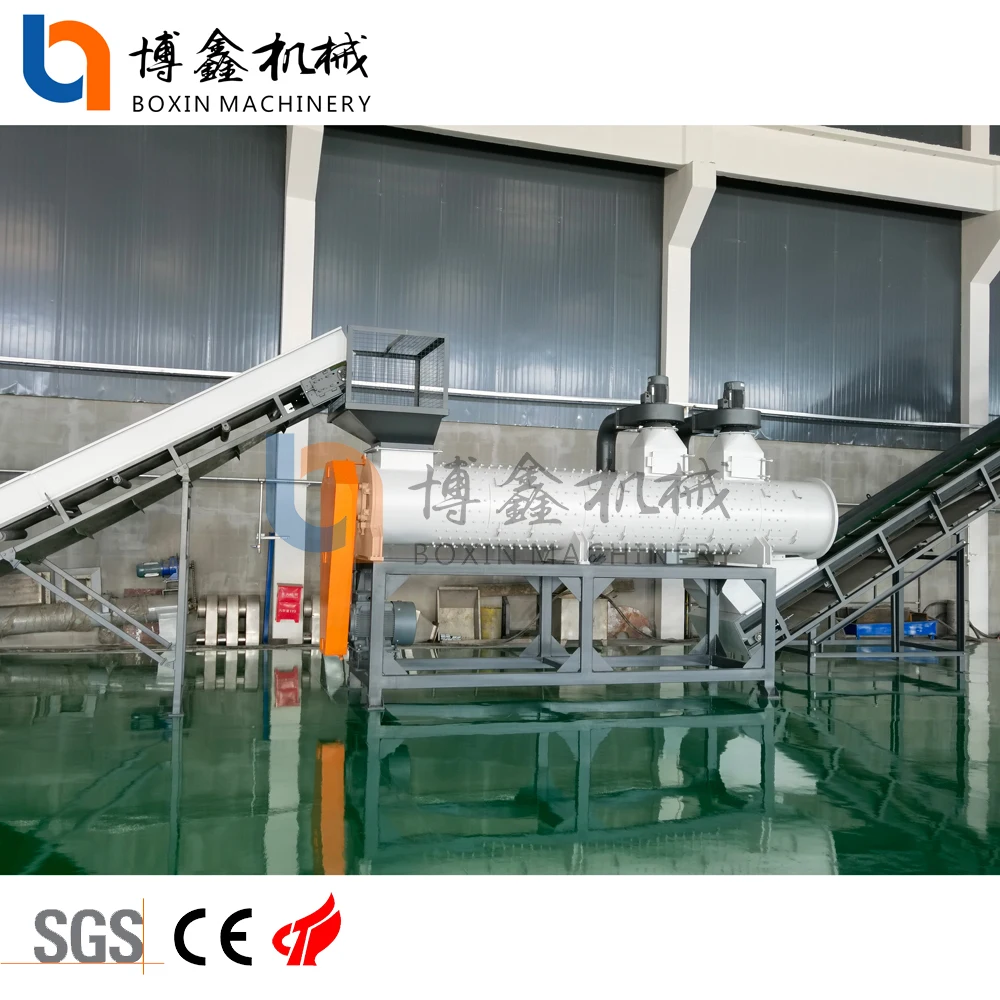

1. This Plastic PET Bottle Recycling Machine mainly used for dealing with waste PET bottle, etc.

2. To separate PET bottles to flakes from label, cap, oil, garbage.

3. This PET Bottle Recycling Machine is composed of separator, crusher, cold & hot washing system, dewatering, drying, packing system, etc.

4. Easy to operate,Full automatic.

PET Bottle Crushing Recycling Drying Washing Line for Sale

PET Plastic Bottle Recycling Washing Machine for Sale

Working flow of plastic recycling machine for bottle to bottle

Conveying PET bottle→lable remover→ manual sorting table → wet crusher→screw loader →Hot washer→screw loader→high speed friction washer→screw loader→floating washer→screw loader→spray washer → dewater machine → pipe line dryer → label seperator → blower → hopper

Project evaluation

Raw material: waste plastic pet bottle

Finished product: Clean PET flakes:

1. water content: ≤1.5%

2. stacking density: 0.25-0.35 g/m³

3. flakes size: 6-14mm (the size can be design according to customer request)

8-12mm ≥ 90%

≥12mm: ≤ 2%

fine granule: ≤ 3%;

powder: ≤ 5%

4.Power supply: 220V,3phases,60HZ

5.Total electrical needed: about 443kw (actual consumption:(70%-80%)

6.Size:106м*6м*5.8м, the height of factory must be over 6M, production line can be placed in a line or an angle (Need to provide plant lay out drawing.)

7.Water needed: about 6-8t/h. Equip with water treatment if needed.

Model | BXPET-1000 | BXPET-2000 | BXPET-3000 | BXPET-5000 |

Capacity(KG/H) | 1000 | 2000 | 3000 | 5000 |

Water consumption(T/H) | 3--5 | 6--8 | 10--12 | 12--15 |

Power Consumption(T/H) | 210--260 | 400-460 | 600-670 | 920-1200 |

Staff(person) | 4-5 | 5--6 | 6-8 | 6-8 |

Area covered(M2) | 85*5*5 | 110*6*6 | 135*6*6 | 150*8*7 |

De-baler

Trommel

Usage: Separate different impurities, such as sand, stone, metal and so on according to the size of the holes

Label remover

Usage: for removing the labels by friction between screen and arms

Steel table

1.The main frame adopts thicker square tube and I-beam steel.

2.Manually separate any impurities that can be seen.

Crusher

for crushing the material into smaller size

Floating washer

Usage: Remove labels, caps and so on

High speed de-watering machine

Usage: to get rid of glue, dirties, oil, detergent and etc.

Steam washer

Usage: for wash with hot water and detergent to get rid of oil, dirties and some labels.

The parts which contacts with the wet flakes is made of stainless steel SUS304.Steam boiler (will be provided by buyer) provide hot steam to the steam washer and heat the water to 90-95℃, mix caustic soda or other detergent into the water carefully to clean the flakes.The flakes will stay in the steam washer about 8-10 mins.

Zig-zag label blower

Usage:for separating little amount labels and dust from PET flakes.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packaging | ||

Size | accrding to the product | |

Weight | accrding to the product | |

Packaging Details | The normal package is wooden box(Size: L*W*H).If container is too tigher,we will use pe film for packing or pack it according to customers special request. | |

Welcome new and old customers to visit our factory, we look forward to your call to consult and order, mutual benefit and win-win!