Пресс-формы ПЭТ-Преформа подогреватель полу ручной выдувания бутылки воздуходувка 0-2L 2 гнезда пресс-формы воды бутылка выдувного

- Категория: Stretch Blow Moulding Machines >>>

- Поставщик: Zhangjiagang,Dawson,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 5296.75 $* | 5561.59 $* |

| Aug-19-2025 | 5251.20 $* | 5514.89 $* |

| Jul-19-2025 | 4406.81 $* | 4626.70 $* |

| Jun-19-2025 | 5162.4 $* | 5420.12 $* |

| May-19-2025 | 4495.23 $* | 4720.33 $* |

| Apr-19-2025 | 5073.89 $* | 5327.12 $* |

| Mar-19-2025 | 5029.42 $* | 5280.58 $* |

| Feb-19-2025 | 4984.69 $* | 5233.18 $* |

| Jan-19-2025 | 4940.53 $* | 5187.80 $* |

Характеристики

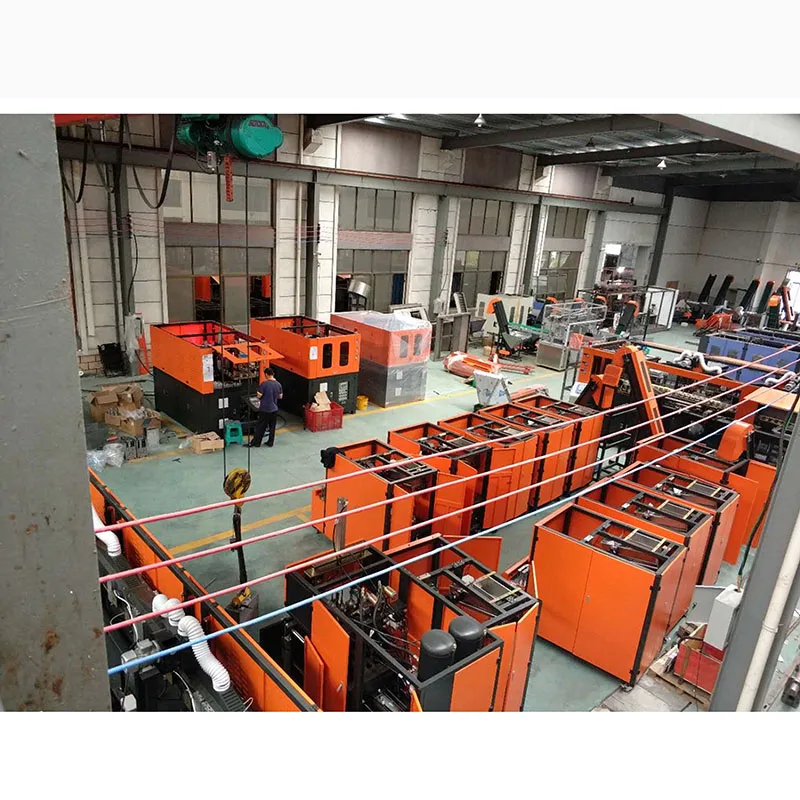

DAWSON MACHINERY & MOULD GROUP

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India, Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia, Venezuela, Peru....

Semi-Auto PET Bottle Blow Moulding Machine

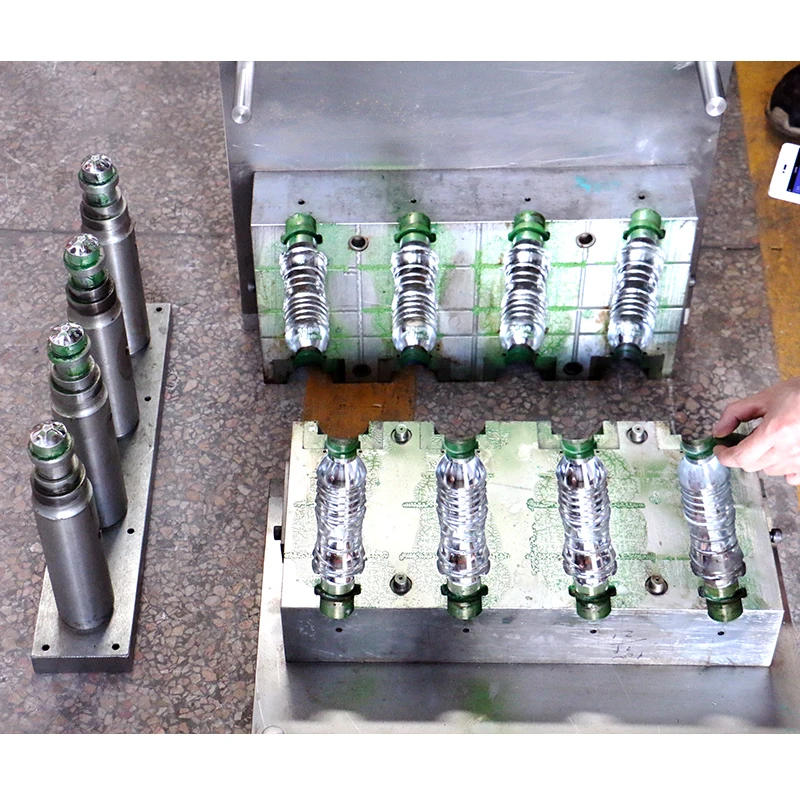

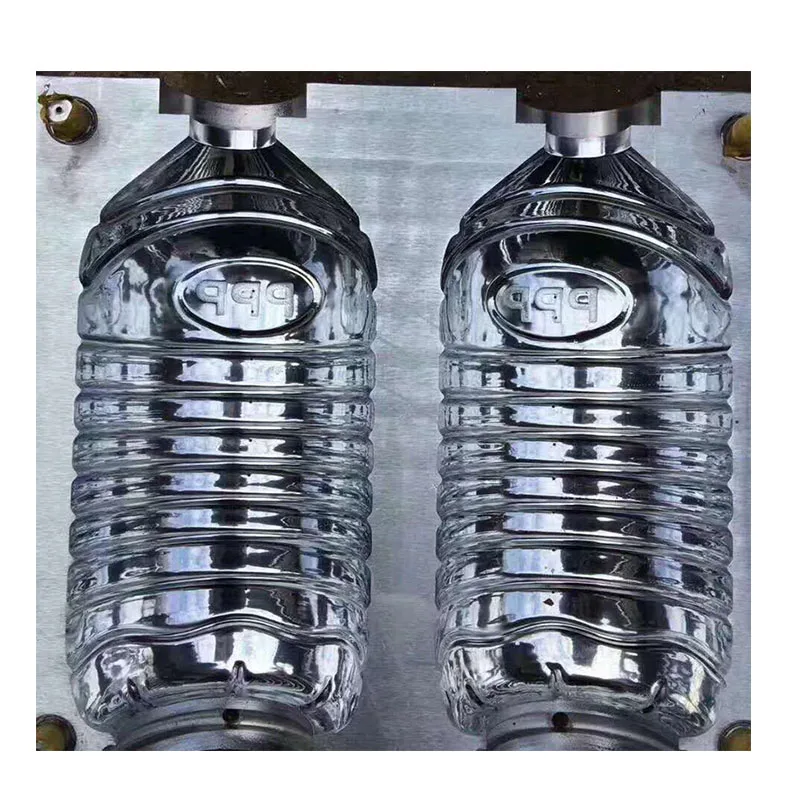

Our Semi Automatic Blow Molding Machine is used in the production of PET water bottles, hot filling bottles, carbonated beverage bottles, edible oil bottles, and pesticide bottles, gallon bottles...etc.

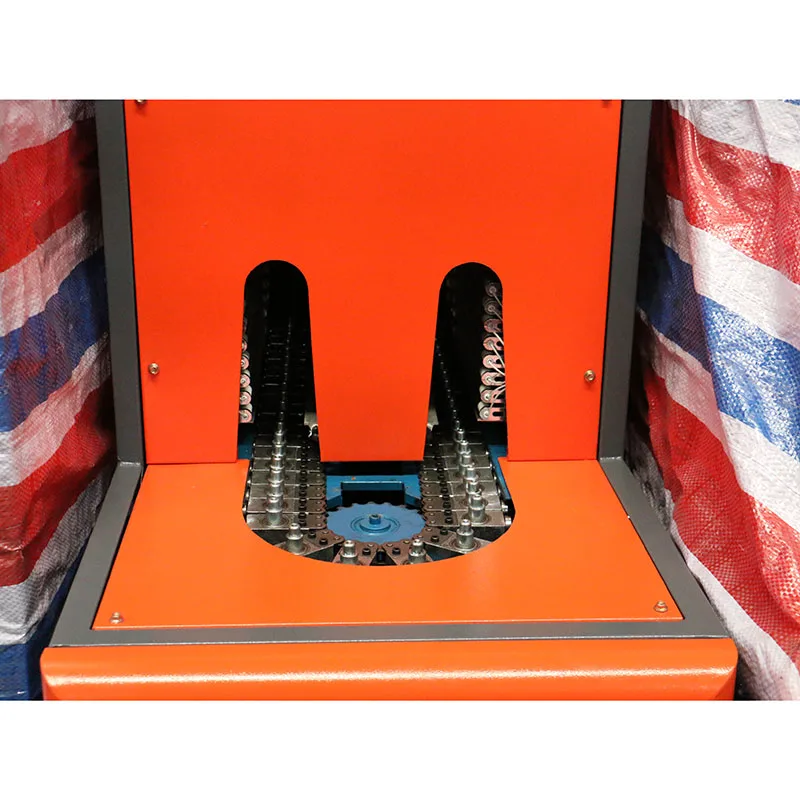

It is composed of a preheater and a blower. Preheater is used to heat the preforms to process temperature, and manually moving the preforms to the blower to make bottles. It is easy to operate, and very economic for smaller manufacturers.

In addition, crystallization varies with different mold design, as a result, the PET bottle produced can stand temperature over 90°C depending on the type of PET material with different crystallization rate. The neck up blowing mode protects the bottle preform from damage during blowing and ensures stable performance.

Main machine (blowert + oven) | Model type | YC-2L-2 | YC-2L-4 | YC-5L-1 |

Product Spec | Max. product volume(L/cav) | 2 | 2L | 5L |

Max. preform neck size(mm) | 100 | 100 | 150 | |

Max. product diameter(mm) | 180 | 180 | 200 | |

Max. product height (mm) | 300 | 300 | 400 | |

Cavities | 2 | 4 | 1 | |

Blow molding part | Die force (KN) | 100 | 100 | 120 |

Die stroke (mm) | 270 | 270 | 320 | |

Max. mould size(mm) | 390*345 | 390*345 | 390*350 | |

Mould thickness | Adjustable | Adjustable | Adjustable | |

Mould spacing(mm) | Adiustable | Adjustable | Adjustable | |

Max. pulling stroke(mm) | 400 | 400 | 500 | |

Operation pressure(Mpa) | 0.8-1.0 | 0.8-1.0 | 0.8-1.0 | |

Operation air pressure consumption (1tr/min) | 200 | 200 | 350 | |

Blow pressure(Mpa) | 1.2-2.8 | 1.2-2.8 | 1.2-2.8 | |

Blow air pressure consumption (1tr/min) | 300 | 300 | 300 | |

Output(pcs/h) | 800 | 1200-1500(500ml bottle) | 350 | |

Machine size(LxWxH)(m) | 1.46*0.58*1.8 | 1.46*0.58*1.8 | 1.56*0.7*1.9 | |

Machine weight(KG) | 650 | 650 | 700 | |

Oven | Temperature grade(rate) | 8 | 8 | 8 |

Heating time(S) | 90-200 | 90-200 | 90-200 | |

Voltage(V) | 220 or as your request | 220 or as your request | 220 or as your request | |

Frequency(HZ) | 50/60 | 50/60 | 50/60 | |

Total power(KW) | 16 | 16 | 16 | |

Oven Size (LxWxH) | 1.35*0.55*1.15 | 1.35*0.55*1.15 | 1.45*0.65*1.15 | |

Oven weight (KG) | 300 | 300 | 330 |

Customer satisfaction is our eternal pursuit...