Лидер продаж Высококачественная профессиональная гидравлическая Зажимная металлическая трубчатая формовочная

- Категория: Tube End Forming Machines >>>

- Поставщик: Zhangjiagang,Kingstar,Machinery,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 5355.13 $* | 5623.87 $* |

| Aug-15-2025 | 5310.93 $* | 5576.80 $* |

| Jul-15-2025 | 4455.27 $* | 4678.16 $* |

| Jun-15-2025 | 5220.33 $* | 5481.58 $* |

| May-15-2025 | 4545.50 $* | 4772.11 $* |

| Apr-15-2025 | 5130.72 $* | 5387.64 $* |

| Mar-15-2025 | 5085.65 $* | 5339.22 $* |

| Feb-15-2025 | 5040.51 $* | 5292.62 $* |

| Jan-15-2025 | 4995.27 $* | 5245.85 $* |

Характеристики

Zhangjiagang Kingstar Machinery CO.,Ltd.

We have been committed to the development and production of various series of pipe processing machines, ranging from pipe bending machine, chamfering machine, cutting machine, end forming machine, saw blade sharpening machine, thread rolling machine and some other machines.

Final Products

Tube end forming machine Sample

Product Description

Single head tube end forming machine.

1. PLC control, hydraulic drive, electrical hydraulic components are imported.

2. Mobile foot switch, with automatic, tight stop, tight stop continuous three functions, high safety.

3. It can be processed in many ways, such as shrinking pipe, expanding pipe, upsetting pipe, etc.

4, the mold is simple to change, easy to elastic production.

2. Mobile foot switch, with automatic, tight stop, tight stop continuous three functions, high safety.

3. It can be processed in many ways, such as shrinking pipe, expanding pipe, upsetting pipe, etc.

4, the mold is simple to change, easy to elastic production.

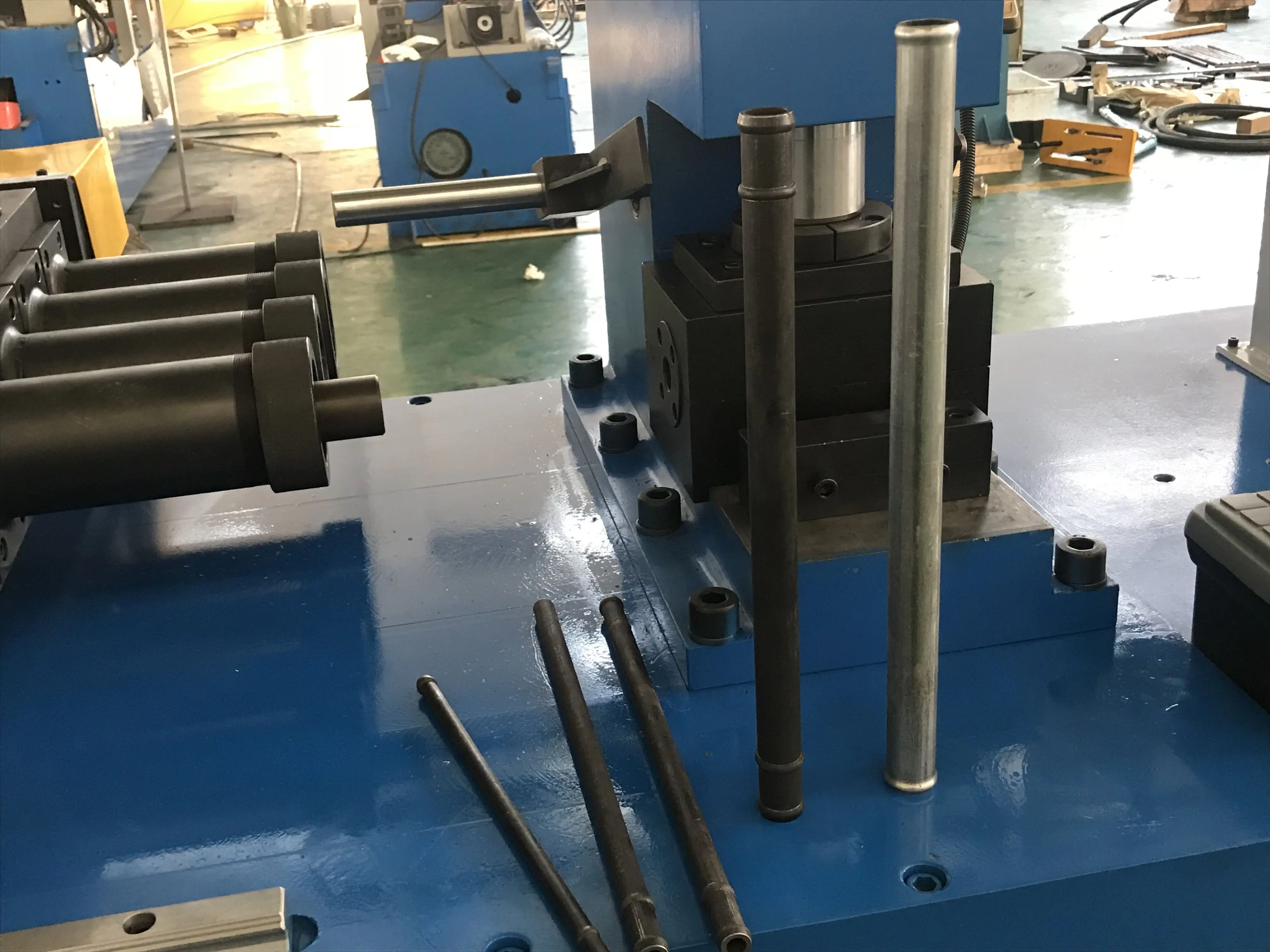

Product Details

Cylinder, limit nut and choke valve.

Independent production of oil cylinder, durable, stable structure, no oil leakage.The end of the cylinder is equipped with a limit nut and a stopper valve, which are used to adjust the stroke and speed of the shrink pipe respectively.

Fixture.

Fixtures and molds (expanding pipe, shrinking pipe, pier bar) can be customized according to pipe fitting and

shrinking pipe requirements.

After limit.

The limit length can be adjusted by adjusting the rear limit nut.

Transposition oil cylinder.

The transposition cylinder drives two molds to move and transposition left and right, which can realize multiple sizes of one pipe fitting.Interceptor valves are installed on the transposition cylinder to control the displacement speed.

Product Paramenters

Specification/Model | TM40 | TM60 | TM80 |

Max processing pipe | Φ40x2.0t | Φ60x 2.0t | Φ80x2.0t |

Max working travel | 100mm | 130mm | 150mm |

Oil pressure | 4.5Mpa | 12Mpa | 12Mpa |

Working speed | 100mm in 3-4sec | 100mm in 3-4sec | 130mm in 5-6sec |

Machine size | 200x55x130cm | 200x60x140cm | 290x70x150cm |

Machine weight | 1100kg | 1250kg | 1600kg |

Recommend Products

CNC pipe bending machine

NC pipe bending machine

Double head pipe bending machine

Pipe cutting machine

Thread rolling machine

Pipe chamfering machine

Saw blade sharpening machine

End forming machine

Rolling machine

Why Choose Us

Zhangjiagang Kingstar Machinery CO.,Ltd.

Kingstar Machinery has been engaged in the production of pipe processing machinery for more than ten years, with strong technical force and strong development force. It has the annual production capacity of more than 1,000 machine tools such as pipe benders. The products have been exported to Europe, America, Middle East, Southeast Asia and other countries and regions for their performance, exquisite quality and perfect service, and are well received by customers.

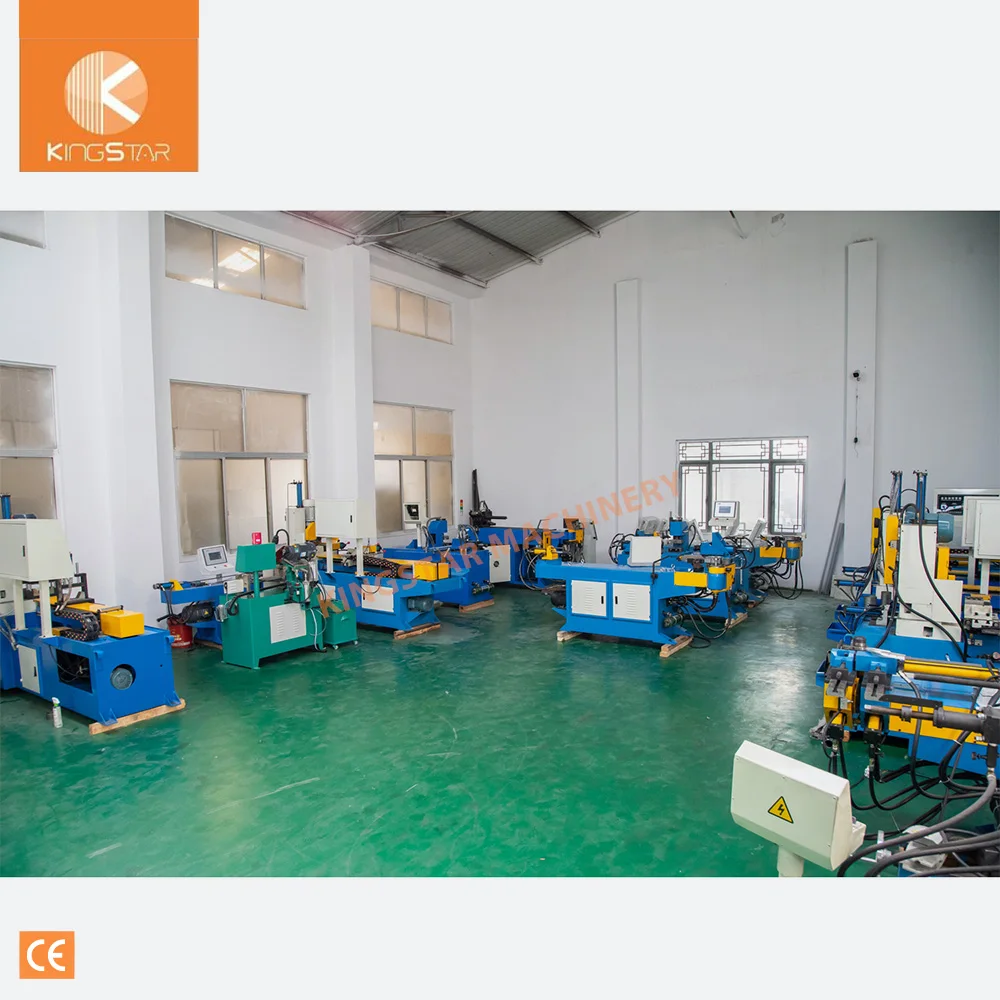

Factory.

It is located in Suzhou Zhangjiagang City, along the Economic circle of Yangtse River Delta,enjoying the highly developed economic expansion and convenient transportation access.

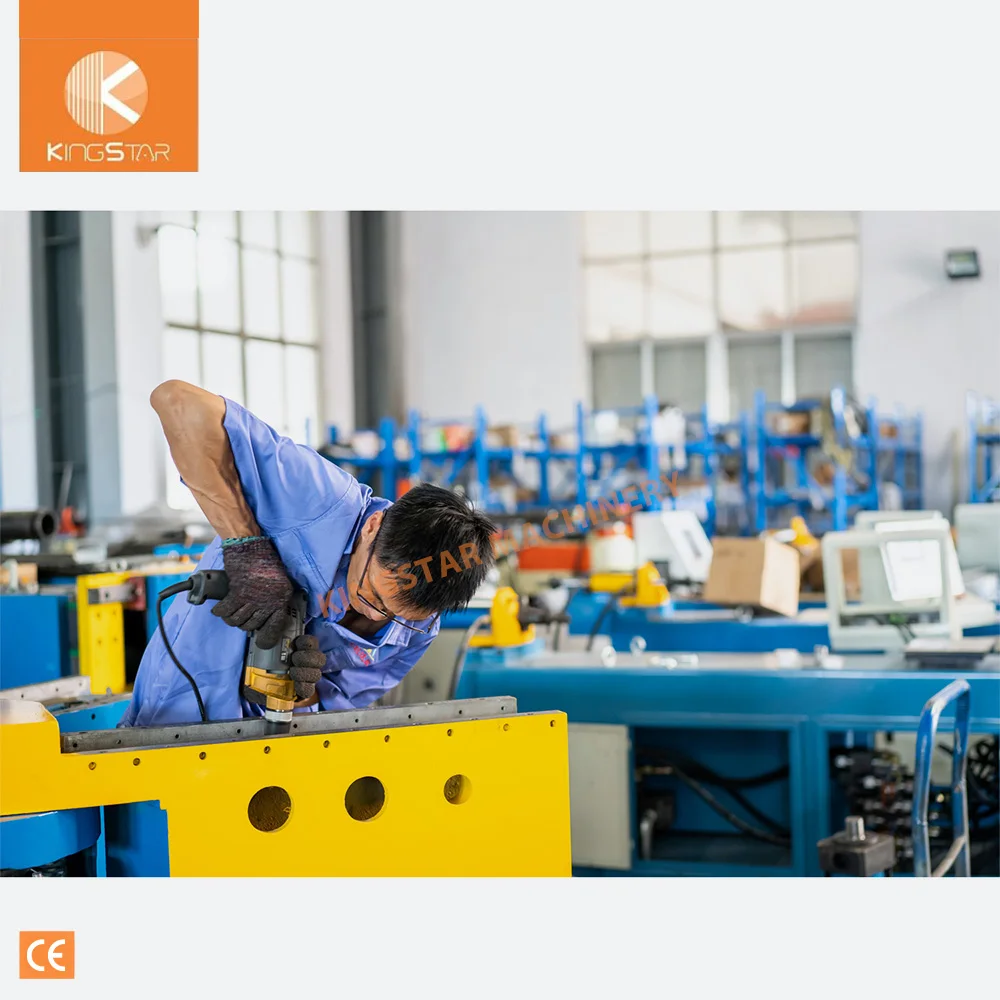

Our team.

Our team is combined with R&D, manufacture, sales, service, and is committed to providing customers with one-stop service. The company attaches great importance to product quality and technical content. Since the establishment of the company, our R&D team has successively developed more than 60 new products and has a number of patented technologies. The company has passed ISO9001: 2000 quality system certification, CE certification and other certifications. In order to improve customer satisfaction, we also set a professional after-sales team.

Certificates.

FAQ

1. Are you a manufacturer or a trading company?

We are a manufacturer with more than ten years of experience.

2. Do you provide any training to ensure that our users can operate the machine well?

We will provide detailed video and instructions for the machine;

3. How long can you provide the warranty?

Our machine has a one-year warranty, and we use all stable components with a long service life.

4. Where is your factory? How do i get there?

Our factory is located in Zhangjiagang City, Suzhou (next to Shanghai). You can fly directly to Shanghai Hongqiao or Pudong Airport.

5. Do you guarantee the safe and reliable delivery of the product?

Yes, we always use high-quality standard export packaging.

6. How about the shipping cost?

The cost of shipping depends on the method you choose to obtain the goods. Express delivery is usually the fastest method, but it is also the most expensive method. Shipping is the best solution for large quantities. For the exact shipping cost, we can only provide you with detailed information after knowing the quantity, weight and method. Please contact us for more information.

We are a manufacturer with more than ten years of experience.

2. Do you provide any training to ensure that our users can operate the machine well?

We will provide detailed video and instructions for the machine;

3. How long can you provide the warranty?

Our machine has a one-year warranty, and we use all stable components with a long service life.

4. Where is your factory? How do i get there?

Our factory is located in Zhangjiagang City, Suzhou (next to Shanghai). You can fly directly to Shanghai Hongqiao or Pudong Airport.

5. Do you guarantee the safe and reliable delivery of the product?

Yes, we always use high-quality standard export packaging.

6. How about the shipping cost?

The cost of shipping depends on the method you choose to obtain the goods. Express delivery is usually the fastest method, but it is also the most expensive method. Shipping is the best solution for large quantities. For the exact shipping cost, we can only provide you with detailed information after knowing the quantity, weight and method. Please contact us for more information.