Машина для переработки сценических отходов пластмассы ПП

- Категория: Plastic Raw Material Machinery >>>

- Поставщик: Zhangjiagang,Boxin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 47600.16 $* | 49980.45 $* |

| Aug-18-2025 | 47200.95 $* | 49560.31 $* |

| Jul-18-2025 | 39600.1 $* | 41580.70 $* |

| Jun-18-2025 | 46400.50 $* | 48720.64 $* |

| May-18-2025 | 40400.25 $* | 42420.80 $* |

| Apr-18-2025 | 45600.30 $* | 47880.14 $* |

| Mar-18-2025 | 45200.38 $* | 47460.42 $* |

| Feb-18-2025 | 44800.30 $* | 47040.78 $* |

| Jan-18-2025 | 44400.57 $* | 46620.80 $* |

Характеристики

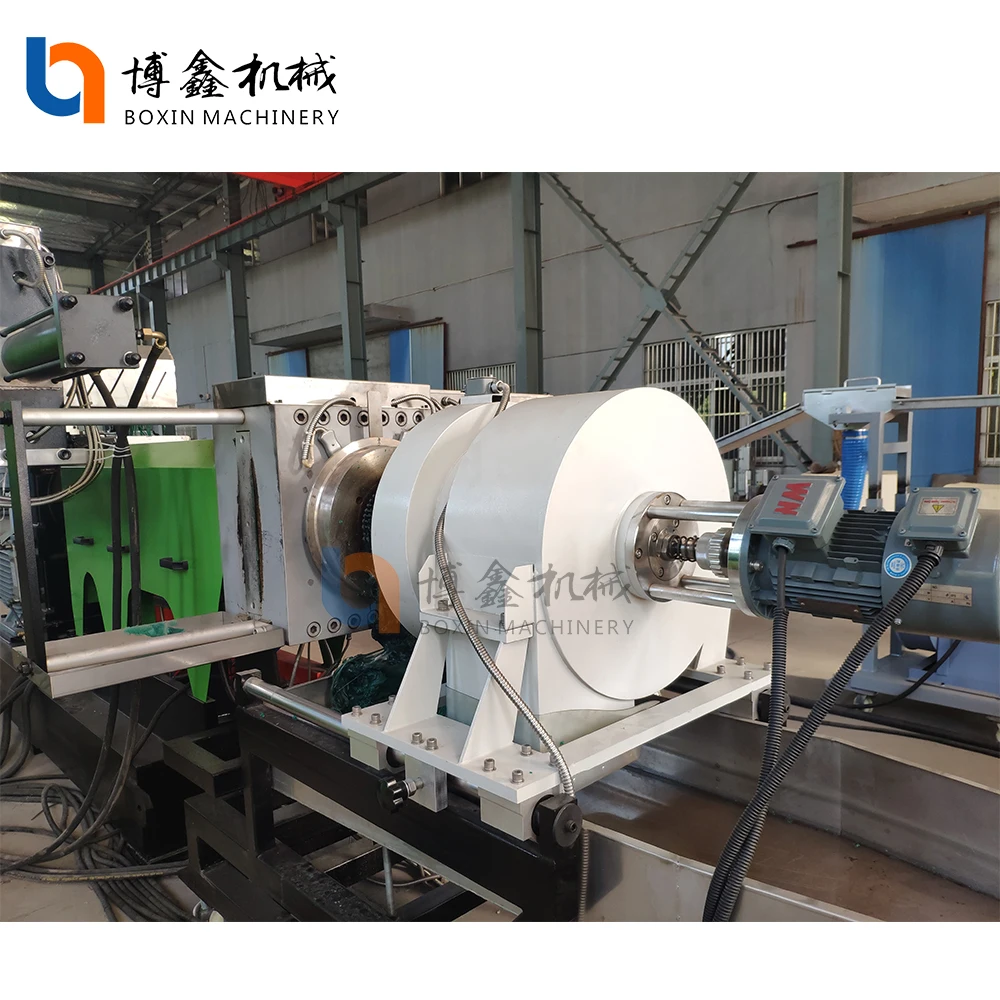

Mother baby stage waste plastic PP PE scrap recycling plastic pellet machine

This HDPE PP PE plastic pellet machine mainly do HDPE hard bottles ,PP PE hard flakes, or film, bags after agglomerating, Adopting special screw design and different technical ,it also can produce etc. various plastic recycling and color mixing pelletizing.

Product Description

Boxin have two types of plastic PP PE scrap recycling pellet machine : one stage and two stags.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and

contamination; And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

mother baby plastic pelletizing machine is especially good for the raw material which contain high moisture, high impurities.

The first stage extruder adopts exhaust type barrel screw, which can effectively de-gassing and eliminate the moisture and

contamination; And the second extruder usually adopts small L/D extruder, further plasticizing the material and filter contamination which can achieve stable extrusion.

Raw Material

Details Images

1 | Stainless Steel Feeder |

Usage | single screw feeder, feeding smoothly and evenly |

Stainless Steel Material Body | |

With Spiral Charger | |

Brand | Boxin Machinery |

2 | Single screw Extruder |

Usage | Heating and melting raw materials |

Exhausting gas | |

Barrel, screw material | 38CrMoALA, After nitriding treatment |

Brand | Boxin Machinery |

3 | 2nd Stages Single Screw extruder |

Usage | To make the material more stable |

Barrel, screw material | 38CrMoALA, After nitriding treatment |

L/D | 10:1 |

Brand | Boxin Machinery |

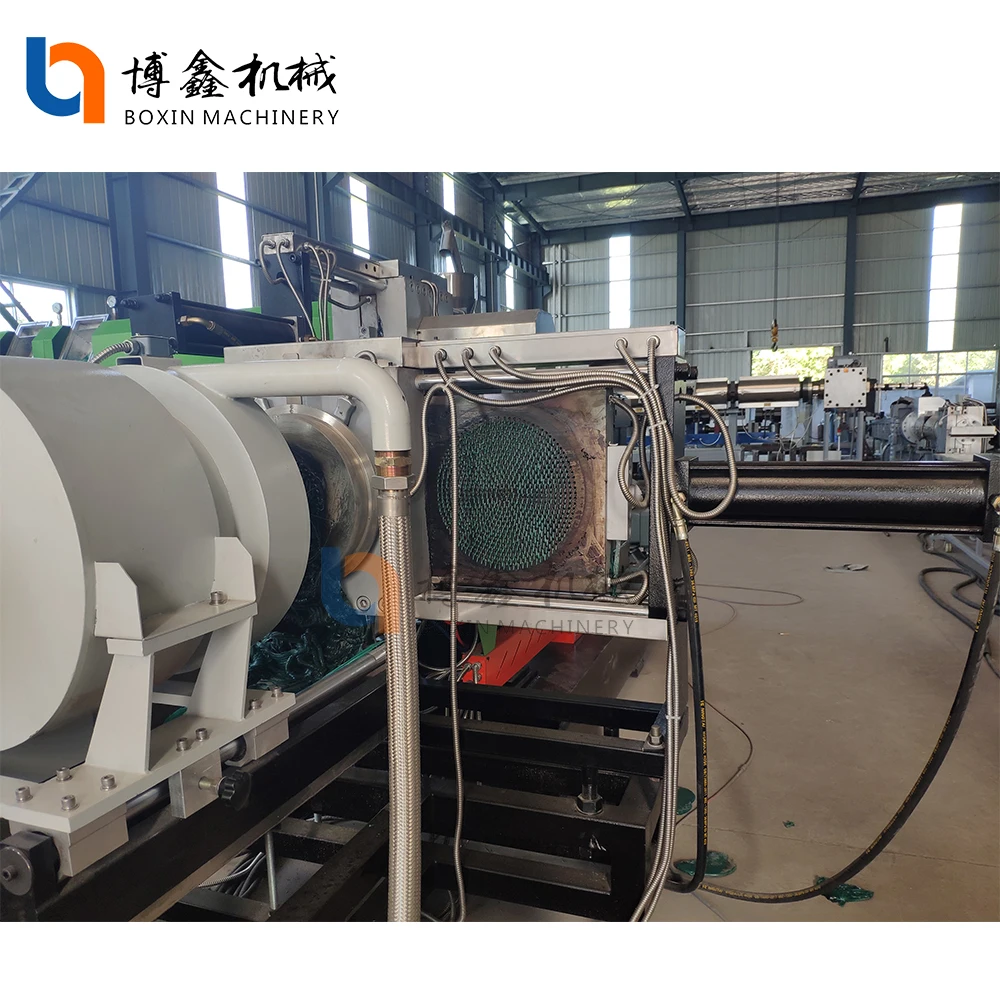

4 | Hydraulic screen changing device |

Plate type | Hydraulic screen changer for No stopping, no leaking |

Motor Power | 2.2kw |

Changing screen time≤2 sec | |

Brand | Boxin Machinery |

5 | Water-Ring cutting system |

Usage | Vertical/Horizonal Water-ring die face hot cutting system |

Speed controlling by frequency conversion | |

Containing | hot cutting die head、diffluence strick, water-ring cover, knife rest |

Brand | Boxin Machinery |

6 | Water Tank |

Usage | cooling pellets |

Length | The length will be made with situation. |

Material of the part in contact with the material Stainless steel | |

Brand | Boxin Machinery |

7 | Vibration Sieve Machine |

Usage | Remove bad pellet and keep good pellet |

Motor power | 0.25kw*2 |

Material of the part in contact with the material Stainless steel | |

Brand | Boxin Machinery |

8 | Storage silo |

Usage | Storage the final pellets to with a bag |

Effective capacity | 700L |

Material of the part in contact with the material Stainless steel | |

Brand | Boxin Machinery |

Product Paramenters

One Stage plastic pellet making machine

Model | STSJ90 | STSJ100 | STSJ120 | STSJ130 | STSJ160 | STSJ180 |

90Screw Dia. | 90 | 100 | 120 | 130 | 160 | 180 |

L/D Ratio | 33:1 | 33:1 | 33:1 | 33:1 | 33:1 | 33:1 |

Capacity(kg/h) | 150-200 | 200-250 | 250-350 | 450-550 | 650-800 | 800-1000 |

Extruder Main Motor(kw) | 55 | 75 | 90 | 132 | 160 | 250 |

Total Electric Power(kw) | 110 | 135 | 160 | 215 | 263 | 375 |

Two Stage HDPE plastic pellet making machine

Model | STSJ90/90 | STSJ100/100 | STSJ120/120 | STSJ130/130 | STSJ160/160 | SJ180/200 |

Screw Dia. | 90 | 100 | 120 | 130 | 160 | 180 |

L/D Ratio | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 | 28:1/10:1 |

Capacity(kg/h) | 150-200 | 200-250 | 250-350 | 450-550 | 650-800 | 800-1000 |

First Stage Motor (kw) | 55 | 75 | 90 | 132 | 160 | 250 |

Second Stage Motor (kw) | 22 | 30 | 37 | 45 | 55 | 75 |

Total Electric Power(kw) | 150 | 185 | 220 | 285 | 350 | 490 |

Workflow Chat

Company Profile

BOXIN Machinery is a creative company, focusing on the technology R&D of plastic recycling, and providing the equipment and

solutions for plastic washing, recycling and granulating.

BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics

recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic

pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

solutions for plastic washing, recycling and granulating.

BOXIN Machinery plastic recycling technology mainly applied in the field of waste plastic regrinding, washing and regranuling.

Thanks to the R&D ability and well-understanding industries experience, BOXIN Machinery can provide the customized plastics

recycling solutions to customers.

Typical productions Machinery can provide are: plastic washing line for PET bottles, PP PE film bags, HDPE Bottles , Plastic

pelletizing recycling line for clean PP PE material , plastic shredder and crushers etc.

After-sale Service

Best After-sale service

* 24h online service for support your machine running.

* Video installation support

* Video technical support.

* Door-to-door service in some areas.

* After the epidemic, an engineer can be arranged for local service.

Exhibition