Яркая печь для отжига металла стали закалки термообработки

- Категория: Industrial Furnace >>>

- Поставщик: Guangzhou,Shangguan,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 17850.4 $* | 18743.23 $* |

| Aug-18-2025 | 17700.97 $* | 18585.74 $* |

| Jul-18-2025 | 14850.59 $* | 15593.82 $* |

| Jun-18-2025 | 17400.91 $* | 18270.56 $* |

| May-18-2025 | 15150.26 $* | 15908.15 $* |

| Apr-18-2025 | 17100.52 $* | 17955.35 $* |

| Mar-18-2025 | 16950.96 $* | 17798.31 $* |

| Feb-18-2025 | 16800.38 $* | 17640.49 $* |

| Jan-18-2025 | 16650.84 $* | 17483.27 $* |

Характеристики

Bright annealing metal steel tempering heat treatment furnace for scissors factory

--- A-Z Complete Turn-key Project Provided

Parameters

---------------

| Item | YLGD45-18 |

| Main motor power | 45KW |

| Rated temperature | 1150 degrees |

| Steel strip width | 160 mm |

| Steel strip material | 1Cr18Ni9Ti |

| Running speed of steel strip | 30-300mm/min (frequency control) |

| Temperature control accuracy | ± 1 °C |

| Effective cross section of furnace tube | width 180mm * height 65mm |

| Main body length of heating furnace | 2400mm |

| Dimensions(L*W*H) | 9400*1100*1200 mm |

The continuous gas shielded heat treatment furnace is mainly used for the continuous bright quenching of Martensitic stainless steel, bright annealing of austenitic stainless steel ,various copper materials and copper alloy intermediate recrystallization annealing ,final annealing and stress relief treatment, etc. Such as SUS420J2, 3Cr13, 410, 310, 304, 316, 420 and so on...

Features:

* The surface is bright without oxidation after heating

* Energy saving and high thermal efficiency

* Enviromental-friendly

* User-friendly

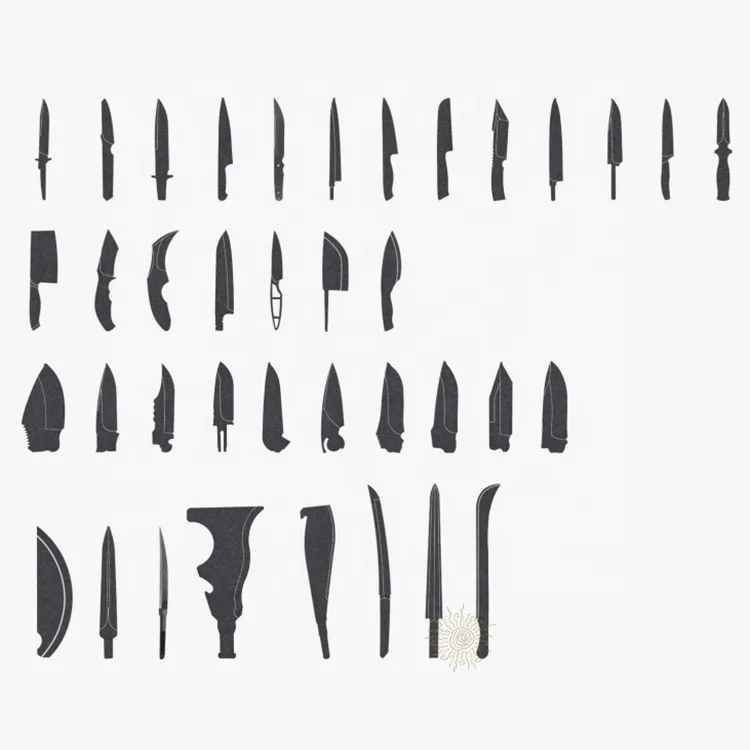

End Products

---------------

Services

-----------

Pre-sale Service

1. Popular design, new trend information sharing.

2. Return of investment analysis.

3. A-Z solution flow chat design.

4. Production process design and feasibility study.

5. Machines line arrangement.

In-sale Service

1. Machines and molds quality control during manufacturing and after finish.

2. Independent verification for each process.

After-sale Service

1. Plant layout proof & production line positioning.

2. Production line installation & debugging.

3. Training after shipment in buyer's factory.

4. Annual visit on site.

Upgraded Service

1. Market trend & latest fashion broad casting.

2. Continuous & systematic training for management, maintenance team & operators.

3. Back up for the regular production.

4. Support in new R&D realization.