Листы из нержавеющей стали № 4 шлифовальная машина для металлических алюминиевых катушек и листов Скотч

- Категория: Metal Polishing Machine >>>

- Поставщик: Anhui,Advanced,Grinding,Tools,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 1895396.22 $* | 1990166.41 $* |

| Aug-18-2025 | 1879469.64 $* | 1973442.43 $* |

| Jul-18-2025 | 1576842.9 $* | 1655684.98 $* |

| Jun-18-2025 | 1847613.1 $* | 1939994.33 $* |

| May-18-2025 | 1608698.23 $* | 1689133.48 $* |

| Apr-18-2025 | 1815758.69 $* | 1906546.1 $* |

| Mar-18-2025 | 1799830.5 $* | 1889822.75 $* |

| Feb-18-2025 | 1783902.86 $* | 1873097.67 $* |

| Jan-18-2025 | 1767975.89 $* | 1856374.13 $* |

Характеристики

Features:

•Used to remove longitudinal burrs from laser cutting, stamping and waterjet cutting workpieces.

•The equipment can complete large burr rough grinding and surface wire drawing at one time. It is used for large surface sanding treatment to remove scratches and make the surface uniform, which can remove the oxide layer on the surface of the workpiece

powerfully.

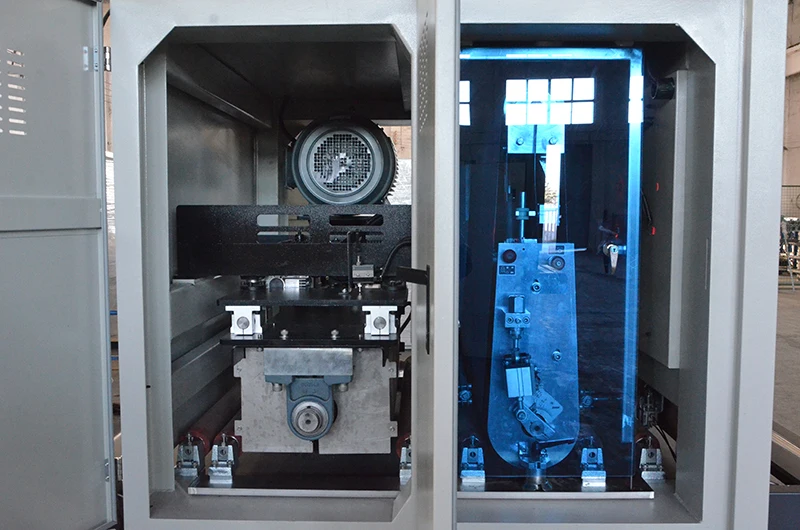

ADV-508Rr Deburring machine with working width 1300mm(Abrasive belt+Roller brush)

The standard available width is 650mm, 1000mm,1300mm, or customized.

![]()

•Used to remove longitudinal burrs from laser cutting, stamping and waterjet cutting workpieces.

•The equipment can complete large burr rough grinding and surface wire drawing at one time. It is used for large surface sanding treatment to remove scratches and make the surface uniform, which can remove the oxide layer on the surface of the workpiece

powerfully.

ADV-508Rr Deburring machine with working width 1300mm(Abrasive belt+Roller brush)

The standard available width is 650mm, 1000mm,1300mm, or customized.

Automatic feeding guide and machine frame:

![]()

![]()

Details Images

Number of abrasive belts optional:

![]()

Functions and advantages of deburring machine:

1. Pneumatically controlled eccentric sanding roller, which can be lifted and lowered independently. When equipment fails, all sanding rollers automatic lifting to protect the material from damage;

1. Pneumatically controlled eccentric sanding roller, which can be lifted and lowered independently. When equipment fails, all sanding rollers automatic lifting to protect the material from damage;

2.Special customized type tensioning cylinder with a large bore and high stability;

3.Independent bearing hanging plate, easy to adjust;

4.Automatic thickness measurement function, automatically locate the thickness of the plate;

5.Damping belt deviation knob, adjust the deviation of the belt, the operation is simple and convenient.

6.The deburring machine can be used in the wet process or dry process.

3.Independent bearing hanging plate, easy to adjust;

4.Automatic thickness measurement function, automatically locate the thickness of the plate;

5.Damping belt deviation knob, adjust the deviation of the belt, the operation is simple and convenient.

6.The deburring machine can be used in the wet process or dry process.

7.Convenient opera:on, touch screen opera:on panel, LED light source inside the equipment, easy to observe the processing status of the workpiece.

8. The automatic deburring machine has different combinations of grinding heads, which are for different requirements of workpieces.For laser cutting stamping parts,it can do deoxidizing, grinding, deburring, and hairline.

![]()

Polishing roller configuration:

1. The polishing wheel can make the surface of the workpiece reach the HL and SB effect.

2. Frequency conversion speed regulation of polishing wheel

3. It can lift and swing independently, so that the workpiece can achieve different effects

4. Linear speed of polishing roller: 3-12.5m/s, frequency conversion speed regulation

3. It can lift and swing independently, so that the workpiece can achieve different effects

4. Linear speed of polishing roller: 3-12.5m/s, frequency conversion speed regulation

After deburring and drawing:

![]()

![]()

PRODUCT CONFIGURATION:

Siemens or ABB high power engine

Delta PLC touch screen

NSK bearings

Specification

Spindle Speed | 2800r/min |

Feed Speed | 0.5-5m/min frequency speed |

Machine Size | 2150*2250*2400mm |

Available Width | 30-1300mm |

Available Thickness | 0.5-60mm |

Belt Size | 2200*1320 mm |

No.1 Motor Power | 30kw(abrasive belt) |

No.2 Motor Power | 22kw(Roller brush) |

Delivery Motor Power | 4 kw |

Lift Motor Power | 0.55 kw |

Water pump power | 0.75kw(for coolant filter system,optional part) |

Warranty | 2years |

Machine weight | 3500 kg |

For more parameter information, please click here

Company Profile

![]()

ADV is a new brand opened in the end of 2018, but the factory already has 25 years of designing and producing deburring machine, grinding machine and polishing machines. The original intention is to create a brand which is most reliable in China and most famous in the world. We made a plan to finish it within 5 years. We will take priority for all products we were and are selling out and best service for each order. We do believe in our original intention and

keep moving to achieve it!

Anhui Advanced Grinding Tools Company has been adhering to the concept of excellent quality and reasonable price. We are committed to optimize the supply chain, strictly control the quality, supervise the production and debugging process of machines, and ensure the delivery of high-quality products to customers. In addition, we have experienced sales and service personnel to provide customers with high-quality pre-sale, after-sales and technical support services.

The company actively explore foreign markets, advocate the business philosophy of integrity management, promote the development of customers is our driving force. Our products are exported to Europe, America and Southeast Asia.

![]()

Certifications

![]()

Exhibition

![]()

Packing & Delivery

Ports:

Shanghai Port / Ningbo Port / Customer Demand

![]()

![]()

![]()

Our Services

1, Overseas after-sales service is available.

2, Two years warranty.

3, Foundation drawings, manual book, electric wiring diagram, electric manual book, and maintenance book, etc. provided.

4, We visit each country every year for free technical instructions.

2, Two years warranty.

3, Foundation drawings, manual book, electric wiring diagram, electric manual book, and maintenance book, etc. provided.

4, We visit each country every year for free technical instructions.

Our overseas service photo show:

![]()

FAQ