AWS-PE(017) профессиональное изготовление производство промышленная стиральная

- Категория: Recycle Washing Line >>>

- Поставщик: Jiangsu,Aceretech,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 2380.63 $* | 2499.20 $* |

| Aug-17-2025 | 2360.84 $* | 2478.47 $* |

| Jul-17-2025 | 1980.93 $* | 2079.27 $* |

| Jun-17-2025 | 2320.60 $* | 2436.97 $* |

| May-17-2025 | 2020.12 $* | 2121.67 $* |

| Apr-17-2025 | 2280.70 $* | 2394.38 $* |

| Mar-17-2025 | 2260.58 $* | 2373.2 $* |

| Feb-17-2025 | 2240.6 $* | 2352.80 $* |

| Jan-17-2025 | 2220.96 $* | 2331.67 $* |

Характеристики

AWS-PE(017) Professional manufacturer Industrial Washing Machine

Product Description

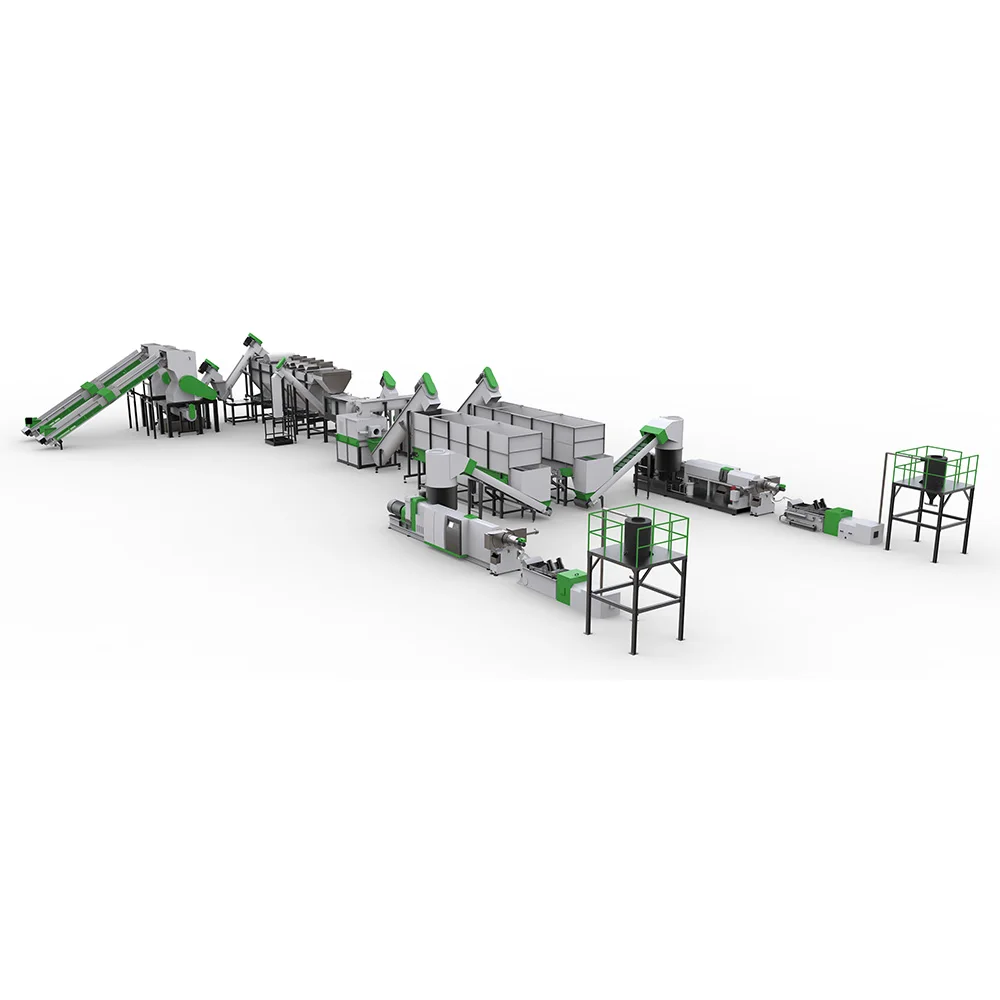

With years of technology modification and process experience precipitation, ACERETECH has a variety of different solutions for recycling PP PE scraps (LDPE/LLDPE film, PP woven bags, PP non-woven, PE bags, milk bottles, cosmetic containers, vegetable and fruit boxes). With advanced modular design, ACERETECH can freely combine each standard module to provide to customers specialized solutions.

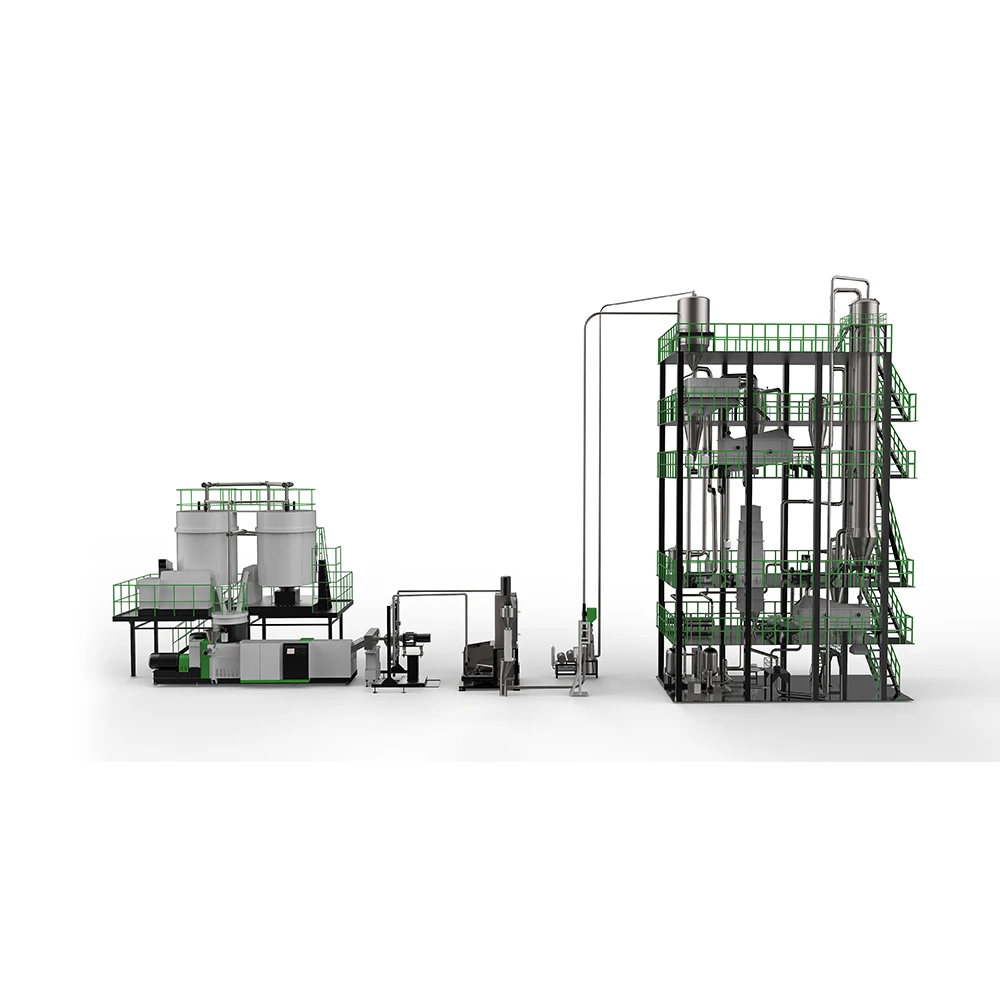

Product Name : AWS- HDPE/PP/PS/ABS/PC/PET Plastic Washing Recycling Machine

In the field of HDPE/PP/PS/ABS/PC/PET recycling projects. Most of the materials come from urban and industrial collection sites,their sizes vary, and the composition of raw materials is different from country to country, even though the composition of HDPE/PP/PS/ABS/PC/PET in the same country is totally different.

ACERETECH team integrated the cleaning line technology in Europe and China and continuously optimized it. Finally, it developed a series of modular equipment that can adapt to the different characteristics of HDPE/PP/PS/ABS/PC/PET materials. Aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling. It can realize a cleaning and recycling line and handle hard materials at the same time. And flexible plastic.

Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular.

Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

Product Name : AWS- HDPE/PP/PS/ABS/PC/PET Plastic Washing Recycling Machine

In the field of HDPE/PP/PS/ABS/PC/PET recycling projects. Most of the materials come from urban and industrial collection sites,their sizes vary, and the composition of raw materials is different from country to country, even though the composition of HDPE/PP/PS/ABS/PC/PET in the same country is totally different.

ACERETECH team integrated the cleaning line technology in Europe and China and continuously optimized it. Finally, it developed a series of modular equipment that can adapt to the different characteristics of HDPE/PP/PS/ABS/PC/PET materials. Aiming at blow molding packaging bottle/box/cup/barrel/bucket and injection waste recycling. It can realize a cleaning and recycling line and handle hard materials at the same time. And flexible plastic.

Including sorting, size reduction, metal removing, cold and hot washing, high efficiency friction washing and drying modular.

Which can remove ferrous and nonferrous metals, sand, oil, glue, paper and many other different contaminants efficiency.

Aceretech Recyclable Plastics Include:

* LLDPE/LDPE/HDPE/PE/EPE film, crushed material, lithium battery film, foamed pearl cotton

* PP/OPP/BOPP/CPP film, woven bag,

non-woven fabric (melt blown)

* PA66 fishing net, silk, factory trim, carpet

* PET/BOPET bottle flakes, film, silk, waste cloth, foam,optical film

* PTT wire

* EPS/XPS crushed material, cold briquetting foam, hot melt foam, insulation board

* HIPS/PC/ABS home appliance housing, electronic waste, factory plastic

* PVB crushed material, flakes

* PU

Product Paramenters

Device parameters | ||||||||

Size | Capacity | Motor Power | Equipment footprint | |||||

AWS PE 05 | 500kg/h | 150KW | 120m 2 | |||||

AWS PE 10 | 1000kg/h | 190KW | 260m 2 | |||||

AWS PE 20 | 2000kg/h | 290KW | 380m 2 | |||||

Unit energy consumption | ||||||||

Content | Average energy consumption per ton of bottle | |||||||

Electricity | 180-250KW | |||||||

Water | 1.5-3T | |||||||

Compressed air | 0.5-1m 3 | |||||||

Steam (optional) | 0-100KG | |||||||

Detergent (optional) | 0-5KG | |||||||

Suitable Products

Product Detail

Main components of PE film washing line:

1. Shredder/Crusher

2. Pre-washing machine

3. Friction washer

4. Flotation/floating separation tank

5. Friction washer

6. Drying unit (Centrifugal/Squeezer, warm air pipe dryer)

7. Storage silo

8. Electrical control cabinet

1. Shredder/Crusher

2. Pre-washing machine

3. Friction washer

4. Flotation/floating separation tank

5. Friction washer

6. Drying unit (Centrifugal/Squeezer, warm air pipe dryer)

7. Storage silo

8. Electrical control cabinet

Belt conveyor

Conveying raw materials into next parts.

1. PVC/Rubber belt

2. Metal detector as an option

3. With inverter to adjust speed

1. PVC/Rubber belt

2. Metal detector as an option

3. With inverter to adjust speed

Shredder

1. Bigger rotary knives, very tough.

2. Bigger rotor, more powerful.

2. Bigger rotor, more powerful.

3. Automatic oil supplement system.

4. Various screen sizes.

5. Thick and tough shredder body.

4. Various screen sizes.

5. Thick and tough shredder body.

Crusher

1. Crushing with water flushing in.

2. 3/5/7 rotor design.

3. Knife adjustment outside chamber.

4. Low noise.

5. Bearings outside.

2. 3/5/7 rotor design.

3. Knife adjustment outside chamber.

4. Low noise.

5. Bearings outside.

L type belt conveyor

1. For conveying flakes out from shredder.

2. PVC belt.

3. With inverter for speed adjustment

2. PVC belt.

3. With inverter for speed adjustment

Pre-washer

1. To remove heavy contaminates such as mud, stones, metals, thus to protect blades of crusher.

2. Plays a role as Sink-float tank and friction washer as well.

2. Plays a role as Sink-float tank and friction washer as well.

3. Water and energy saving design.

Friction Washer

1. Tough washing unit, removes most of contaminates.

2. Reinforced, mild steel and high speed rotor.

3. Bearings mounted outside.

4. Easy cleaning and maintenance.

5. Stainless steel SUS304 body.

2. Reinforced, mild steel and high speed rotor.

3. Bearings mounted outside.

4. Easy cleaning and maintenance.

5. Stainless steel SUS304 body.

Floating washer

1. With screw-IN and screw-OUT.

2. Special design of inner paddles to guarantee sufficient sediment of heavy impurities.

3. German SEW reducers.

4. Stainless steel SUS304 body.

6. With pneumatic water in-feed-valve, automatic level control via electronic feeler.

2. Special design of inner paddles to guarantee sufficient sediment of heavy impurities.

3. German SEW reducers.

4. Stainless steel SUS304 body.

6. With pneumatic water in-feed-valve, automatic level control via electronic feeler.

Squeezer

1. PLC control

2. Low consumption, high capacity

3. Inverter control

4. European design

2. Low consumption, high capacity

3. Inverter control

4. European design

Storage silo

1. To guarantee non-stop work and stable feeding for downstream extrusion pelletizing line.

2. Non-blockage of film.

3. Cyclone for dust removing.

4. Lower operating costs for maintenance.

5. Different functions of screws.

2. Non-blockage of film.

3. Cyclone for dust removing.

4. Lower operating costs for maintenance.

5. Different functions of screws.

Electrical control cabinet with PLC Control

Intelligent control system.

With CE/CSA/TUV/SGS/ISO standard, all parameters can be set on the touch screen.

1. Electric control component: (Schneider), e.g. Circuit-breaker, AC contact, press button, pilot lamp.

2. For electrical controlling of the entire system.

3. Safety interlock principle.

4. All electrical units: LS, Schneider, ABB.

With CE/CSA/TUV/SGS/ISO standard, all parameters can be set on the touch screen.

1. Electric control component: (Schneider), e.g. Circuit-breaker, AC contact, press button, pilot lamp.

2. For electrical controlling of the entire system.

3. Safety interlock principle.

4. All electrical units: LS, Schneider, ABB.

Cleaned Film

Cleaned film

Our Company

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT WITH US.

● ACERETECH is original manufacturer.

● If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

● The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

SEE ACERETECH MACHINE HOW TO ENSURE THE QUALITY

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 15 years

● After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF ACERETECH MACHINERY

● After finishing the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.

● After the commissioning, we will package the equipment by the standard export package for shipment.

●According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

IF YOU WOULD LIKE TO KNOW MORE INFORMATION ABOUT US, PLEASE DO NOT HESITATE TO CONTACT WITH US.