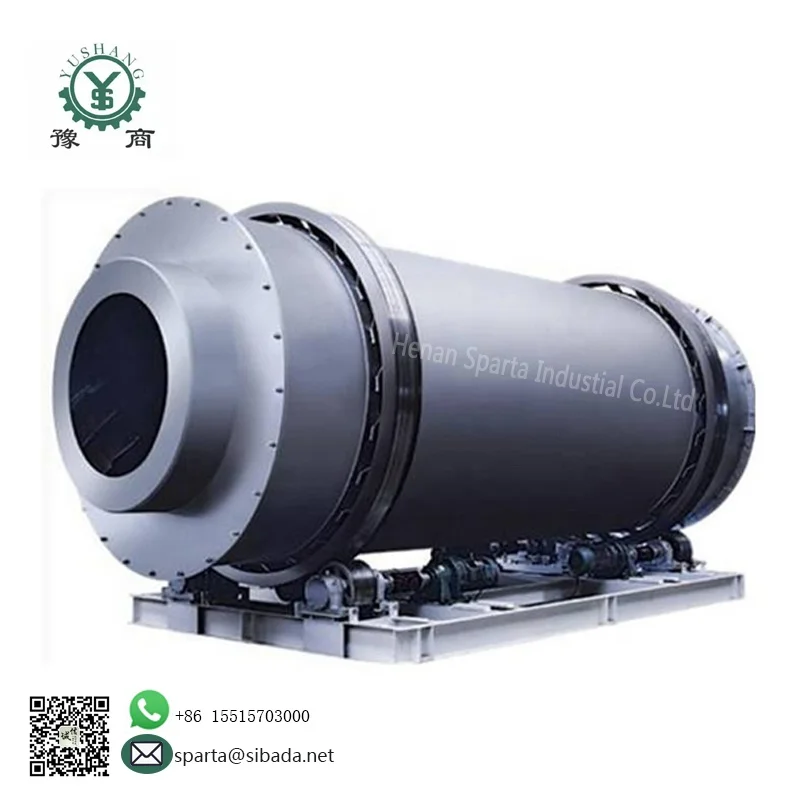

Прямая продажа с завода вращающаяся сушилка дизельным двигателем 20T/сушилка для песка природным газом/сушилка угольным

- Категория: Drum Drying Equipment >>>

- Поставщик: Henan,Sparta,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.15 $* | 0.30 $* |

| Aug-18-2025 | 0.11 $* | 0.39 $* |

| Jul-18-2025 | 0.92 $* | 0.69 $* |

| Jun-18-2025 | 0.65 $* | 0.98 $* |

| May-18-2025 | 0.48 $* | 0.24 $* |

| Apr-18-2025 | 0.99 $* | 0.12 $* |

| Mar-18-2025 | 0.91 $* | 0.46 $* |

| Feb-18-2025 | 0.69 $* | 0.58 $* |

| Jan-18-2025 | 0.72 $* | 0.99 $* |

Характеристики

Factory directly sale 20T Diesel engine rotary dryer

20T Diesel engine rotary dryer is mainly applied for stoving slag, sand, coal, fly ash, iron powder, ore, quartz sand and other particle materials.

20T Diesel engine rotary dryer adopt the saving technology ,fixed structure . Internal cylinder ,middle cylinder and outer cylinder form a since the insulation structure .Special thermal design idew , the elimination of wind tunnel heat loss , increase the heat exchange area and unit volume evaporation intensity , good energy saving effect . The sand dryer is used for drying sand , yellow sand , slag , clay and other raw materials , widely used in building materials , chemical industry , foundry industry , etc , can adapt to a variety of fuels such as coal , oil and gas. It has the following characteristics:

1. The cylinder protect itself, thermal efficiency can up to 95%.The whole length of the dryer reduced to 50% approximately than mono-cylinder and reduced land investment to 50% approximately;

2. Cylinder adopts heat-resistant and wear-resistant steel plate welding with long service life and easy maintenance..High thermal efficiency , temperature of outer cylinder is 60or below(temperature of outer mono-cylinder is high to 150°C);

3. Low temperature of outlet, long-service of dust removal machine. It also can be directly connected to air box pulse bag filter;

4. Without gear and pinion drive, but wheel rotation applied, level operation of the complete machine makes system simple and reasonable;

5. Air heater could match boiling furnace, or oil furnace can also be applied, which can dry materials with size below 20mm;

6. Final moisture index can be adjusted according to requirements of customers.

Type of Three Pass Dryer | SBD-625 | SBD-6215 | SBD-6220 |

Drying capacity | 6-8t/h | 10-15t/h | 20-25t/h |

Length | 2500mm | 2700mm | 5000mm |

Diameter of drum | 2200mm | 2600mm | 2600mm |

Motor powder | 5.5kw | 7.5kw*1 | 7.5kw*2 |

Reducer model | XWD-5 | ZQ350 | ZQ350*2 |

Speed of drum rotation | 4-10r/min | 4-10r/min | 4-10r/min |

Moisture of end products | <5% | <5% | <5% |

700-750℃ | 700-750℃ | 700-750℃ | |

60-80℃ | 60-80℃ | 60-80℃ | |

Burning coke quantity kg/t sand | 7 | 7 | 7 |

1.Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.

2.Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc.

3.Corrosive material: Distillers ‘grains, Fertilizer, animal dung, slag etc.

4.Biomass material: Sawdust, wood chips etc.

1.Simple structure,safe and easy operation.

2.Polishing produdtion;

3.High capacity;

4.Low energy-consumption.

5.International standard with ISO, CE certificate.

6.Flexibility in fuels used (NG, Oil, Coal ect.)

.

7.Capable of installation anywhere in world.

8.In house engineering for custom fit applications

Working Principle:

1.The material first goes into the inside drum, because there are the spiral shape boards fixed in the drum, when the dryer make rotary working, the spiral shape board will stir the material and make the material do movement.

2.When the material reaches the right side of the drum, it will go into the second drum for further drying.

3.The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

Foreign case

Henan Sparda Industrial Co., Ltd. is located in Xingyang Wulong Industrial Zone, Zhengzhou City, which is a collection of independent design, research and development, production, sales, as one of the professional machinery and equipment, dry mortar equipment, real stone paint mixer production line, packaging machine and so on.

Our factory has 15 years of design and development experience, in the quality of survival, to the credibility of security, to service first, widely received by the industry.Our factory's products have been exported to Asia, Africa, North America, South America, such as: Kazakhstan, Armenia, Malaysia, Romania and other countries, well received by foreign customers!

1.In order to provide you the suitable quotation we need to know the following information:

1).What is the raw material for the production line?

2). What is the capacity per hour you required?

3). What is the maximum input size of the raw material?

4). What is the output size and application for the final product? Once we get your answers, I can provide you the best quotation immediately.

Remarks: The price will depend on different models. Reply message you will get 5% discount price.

2.What about Warranty of the products?

Sparta Industrail grants our customers a twelve-month-period warranty from the date of delivery for machines exported from us. During the warranty period, in case any defect of material or workmanship occurred with spare parts in normal operation, we will at our discretion replace or repair the defective parts freely.

3. The reason you choose Sparta Industrial :

1). Professional manufacturer of supplying Dry mortar production line equipment, true stone paint equipment, drying machine equipment, high speed dispersing machine, true stone paint filling machine, packaging machine equipment and other mechanical equipment

2). Experienced and professional R&D team and manufacturing team;

3). Professional sales team consisted of dedicated, dynamic and innovative people with international version.

4). Professional logistics service ensuring safety and timely delivery of products all over the world through ocean, airline, road and railway.

4.What is the difference between your machine and others’?

Every machine is unique and has its pros and cons, as is every mine site. We can help you decide your unique situation and decide which tool is right for your job.

5.If you want to know more about our machine equipment, please send us inquiry or contact us directly.

Contact Us