Автоматическая конвейерная сортировки уплотнитель заполнителя система упаковки Печенье Шоколад палка производства картофельных чипсов типа дой-Пак упаковка производственная

- Категория: Packaging Line >>>

- Поставщик: Foshan,Xinbaolong,Packing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.47 $* | 0.48 $* |

| Aug-19-2025 | 0.39 $* | 0.50 $* |

| Jul-19-2025 | 0.67 $* | 0.17 $* |

| Jun-19-2025 | 0.6 $* | 0.62 $* |

| May-19-2025 | 0.99 $* | 0.46 $* |

| Apr-19-2025 | 0.62 $* | 0.16 $* |

| Mar-19-2025 | 0.66 $* | 0.55 $* |

| Feb-19-2025 | 0.79 $* | 0.76 $* |

| Jan-19-2025 | 0.28 $* | 0.86 $* |

Характеристики

Product Description

Technical parameters:

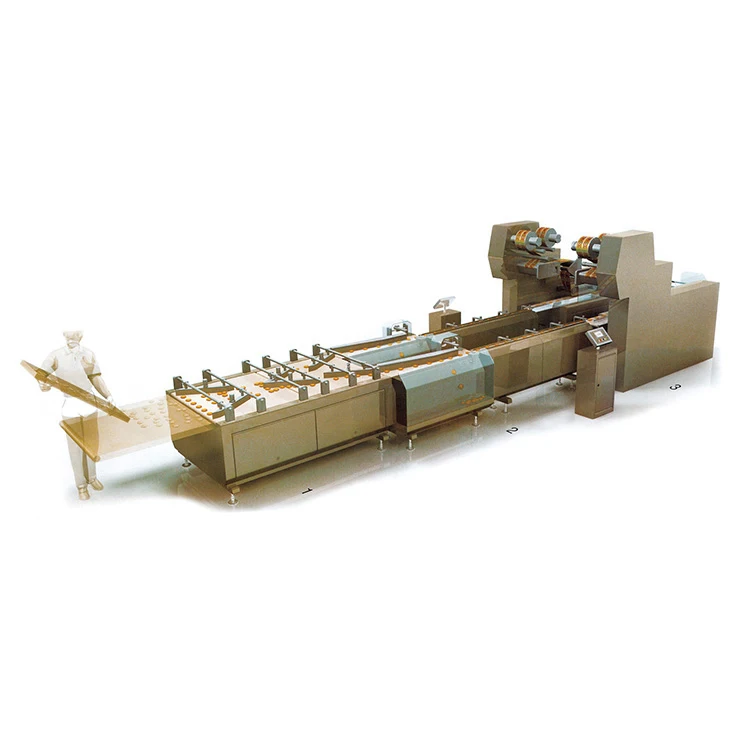

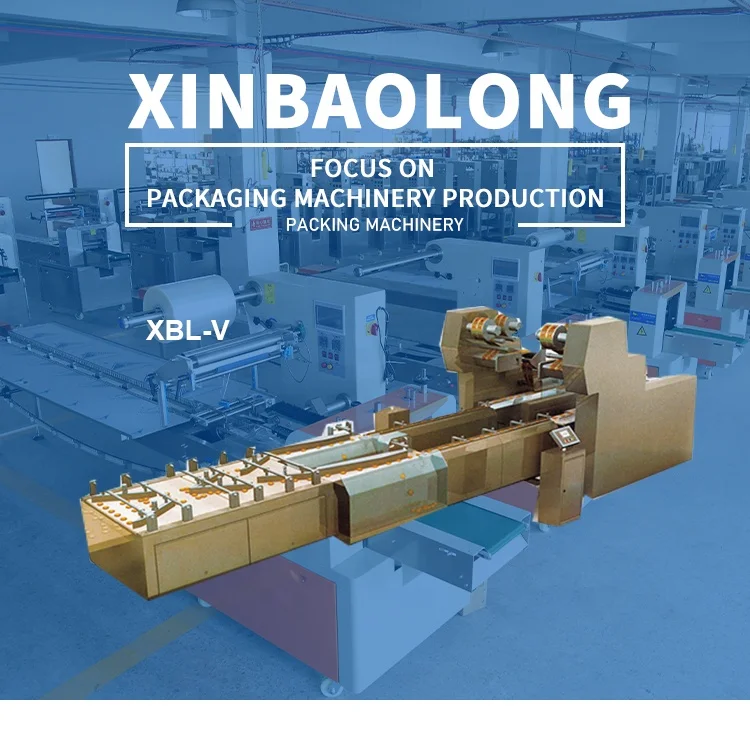

Model | XBL-V |

Dimension | 7650*1500*1130 (adjustable) |

Main wire belt width (mm) | 1000/1200 |

Material handling speed | 30m/min |

System packaging speed | 300-800 bags/min (depending on the product and packaging materials) |

Total power (kw) | Depends on the actual plan of the customer |

Main motor power (kw) | Depends on the actual plan of the customer |

Machine noise (dB) | ≤78 |

Power supply type | 220V 50HZ or 380V 50HZ |

Cross-feeding unit

1. Transitional conveying device;

2. Daily maintenance and cleaning are simple and quick

Material sorting system

1. Accurate positioning of materials through photoelectric detection system and high-efficiency servo control system, fully automatic input to the packaging system;

2. Using cantilever frame design, installation, disassembly, cleaning, simple and convenient;

3. The function configuration is diversified, the expandability is strong, and it is suitable for various material configurations.

Packaging unit

1. Adopt full servo or dual inverter control, stepless speed change, wide adjustment range;

2. The length of the bag is automatically and accurately tracked by the high-sensitivity electric eye, and there is no need to manually adjust the bag length after setting;

3. Each sealing temperature is independently controlled, suitable for a variety of packaging materials, and the sealing is beautiful and firm;

4. It can be freely matched according to customer requirements, and XBL series double frequency conversion pillow packaging machine can be used.

1. Adopt full servo or dual inverter control, stepless speed change, wide adjustment range;

2. The length of the bag is automatically and accurately tracked by the high-sensitivity electric eye, and there is no need to manually adjust the bag length after setting;

3. Each sealing temperature is independently controlled, suitable for a variety of packaging materials, and the sealing is beautiful and firm;

4. It can be freely matched according to customer requirements, and XBL series double frequency conversion pillow packaging machine can be used.

System description

1. The XBL-V dual-channel conveying, sorting and packaging system can be directly connected to the finished product discharge conveyor belt of the front-end processing line to meet the requirements of large-scale and batch production and packaging of single products. It can also use manual dumping of materials to meet multiple specifications Product packaging requirements for small batches and multiple batches.

2. The XBL-V system is equipped with a cross-type automatic conveying and arranging system, which can meet the automatic conveying, arranging and sorting of square, round and bar products, eliminating manual operation.

3. The XBL-V system can be individually designed according to product characteristics to avoid extrusion and deformation of the material. In the case of material congestion, stacking, and unsuccessful steering, it can be automatically rejected without stopping to ensure the continuity and stability of production packaging.

4. The XBL-V system adopts multi-level frequency conversion speed regulation and servo drive control. It can adopt four to eight levels of adjustment and control according to the user's requirements for packaging speed and material shape characteristics, with strong adaptability.

5. XBL-V system adopts humanized design, which is simple and quick to install and disassemble.

6. The XBL-V system is equipped with a number of safety protection measures, including leakage protection, emergency stop function, fault shutdown protection, protective cover (lifting cover to stop), warning lights, etc.

7. The XBL-V system fully automates material conveying, sorting, arranging, feeding and packaging.

2. The XBL-V system is equipped with a cross-type automatic conveying and arranging system, which can meet the automatic conveying, arranging and sorting of square, round and bar products, eliminating manual operation.

3. The XBL-V system can be individually designed according to product characteristics to avoid extrusion and deformation of the material. In the case of material congestion, stacking, and unsuccessful steering, it can be automatically rejected without stopping to ensure the continuity and stability of production packaging.

4. The XBL-V system adopts multi-level frequency conversion speed regulation and servo drive control. It can adopt four to eight levels of adjustment and control according to the user's requirements for packaging speed and material shape characteristics, with strong adaptability.

5. XBL-V system adopts humanized design, which is simple and quick to install and disassemble.

6. The XBL-V system is equipped with a number of safety protection measures, including leakage protection, emergency stop function, fault shutdown protection, protective cover (lifting cover to stop), warning lights, etc.

7. The XBL-V system fully automates material conveying, sorting, arranging, feeding and packaging.

Recommend Products

Our Services

Customer & Exhibition Photos

Company Profile

OUR ENTERPRISE BELIEF

WITH EXCELLENT PRODUCT QUALITY, GOOD COST PERFORMANCE, AND TIMELY AND PERFECT PRE SALES AND AFTER SALES SERVICE, WE ARE WILLING TO WORK WITH CUSTOMERS AND EMPLOYEES TO MAKE PROGRESS AND CREATE A BETTER FUTURE.

Packaging Logistics

FAQ

1.Q: How long of the warranty period?

A: The machine will have one year warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out we received the B/L .

2.Q: What’s the Payment terms?

A: Our payment term is T/T( telegraphic transfer).

30% deposit of the machine should be paid when order and the rest of balance 70% pay before shipment.

3.Q: Can you provide after-sale service?

A: Yes, we have engineers available to service machinery overseas. The service charge, include: service fee USD100/day, VISA fee, board round-trip ticket, room and eat in are buyer's side.

4.Q: What is Our Advantages?

A: 1). Rapid response on any inquiry.

2). Competitive price.

3). Professional inspection department to guarantee quality.

5.Q: Can I come to visit your factory?

A: Of course, you can visit our factory and bring your samples, that you can see how does the machine works with your products and learn to operate it.

A: The machine will have one year warranty. During the warranty year if any of the parts broken not by man-made. We will free charge to replace the new one to you . The warranty will begin after the machine send out we received the B/L .

2.Q: What’s the Payment terms?

A: Our payment term is T/T( telegraphic transfer).

30% deposit of the machine should be paid when order and the rest of balance 70% pay before shipment.

3.Q: Can you provide after-sale service?

A: Yes, we have engineers available to service machinery overseas. The service charge, include: service fee USD100/day, VISA fee, board round-trip ticket, room and eat in are buyer's side.

4.Q: What is Our Advantages?

A: 1). Rapid response on any inquiry.

2). Competitive price.

3). Professional inspection department to guarantee quality.

5.Q: Can I come to visit your factory?

A: Of course, you can visit our factory and bring your samples, that you can see how does the machine works with your products and learn to operate it.

Похожие товары

Системы упаковки и укладки

US $40000-$80000

Автоматическая оберточная упаковка для коробки и картонной коробки

US $55000-$65000