Автоматический цилиндрический Трафаретный принтер для косметических

- Категория: Screen Printers >>>

- Поставщик: Guangzhou,Demasha,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 54740.23 $* | 57477.45 $* |

| Aug-18-2025 | 54280.15 $* | 56994.27 $* |

| Jul-18-2025 | 45540.19 $* | 47817.41 $* |

| Jun-18-2025 | 53360.58 $* | 56028.63 $* |

| May-18-2025 | 46460.91 $* | 48783.87 $* |

| Apr-18-2025 | 52440.31 $* | 55062.0 $* |

| Mar-18-2025 | 51980.48 $* | 54579.51 $* |

| Feb-18-2025 | 51520.86 $* | 54096.29 $* |

| Jan-18-2025 | 51060.19 $* | 53613.5 $* |

Характеристики

Products Description

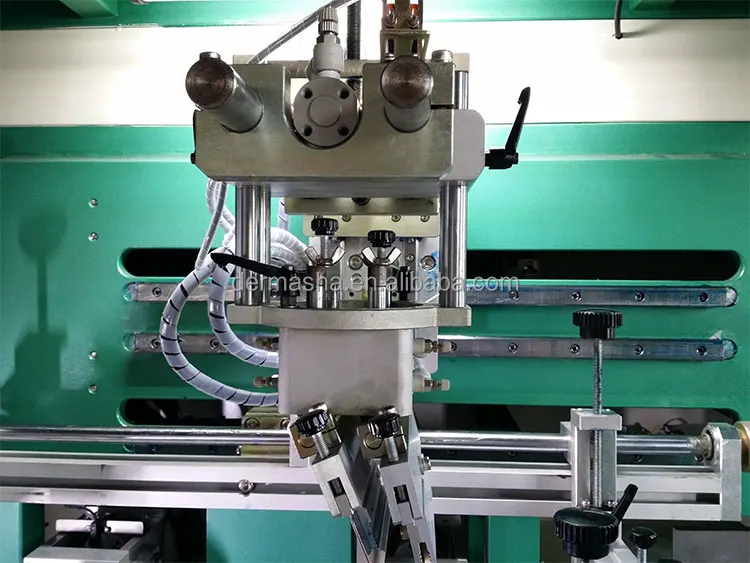

DM-200 Automatic Silk Screen Printing Machine

This machine is suitable for screen printing of round, oval, square, conical and other special-shaped containers. It has the advantages of convenient debugging and installation, stable and reliable operation, strong versatility, high positioning accuracy, accurate color registration and high printing efficiency. The machine can also use ordinary self-drying ink printing, UV ink printing, high temperature solid ink printing, with high adaptability.

It has outstanding advantages for the following bottle shapes and conditions:

1. Equipped with automatic image positioning system, it can realize the register printing of round bottle without positioning point, with accurate register and high printing efficiency.

2. The elliptical bottle can realize one-time printing with the same color on both sides, greatly improving the printing speed, and can also be printed on one side.

3. The bottle with square plane can realize one-time printing of the same color from one side to four sides, and can also select any surface from one side to four sides.

4. Round, oval, square bottle shape with taper can automatically adjust the taper surface for printing. And the printing effect is good, which solves the technical problems of traditional printing pattern stretching, deformation and so on.

Structural features of the machine:

The machine structure is mainly composed of automatic bottle feeding structure, automatic dust removal device, manipulator automatic feeding structure, servo system transmission structure, automatic printing body (printing system), UV automatic temperature control UV curing system. Using modular program control processor and touch screen display control system, the operation is more stable. Less fixture, easy to change bottle shape, simple debugging and installation, more convenient operation. The core component adopts Yaskawa servo system, which can be equipped with visual positioning system. The machine is stable, with high precision and accurate color registration

1. Equipped with automatic image positioning system, it can realize the register printing of round bottle without positioning point, with accurate register and high printing efficiency.

2. The elliptical bottle can realize one-time printing with the same color on both sides, greatly improving the printing speed, and can also be printed on one side.

3. The bottle with square plane can realize one-time printing of the same color from one side to four sides, and can also select any surface from one side to four sides.

4. Round, oval, square bottle shape with taper can automatically adjust the taper surface for printing. And the printing effect is good, which solves the technical problems of traditional printing pattern stretching, deformation and so on.

Structural features of the machine:

The machine structure is mainly composed of automatic bottle feeding structure, automatic dust removal device, manipulator automatic feeding structure, servo system transmission structure, automatic printing body (printing system), UV automatic temperature control UV curing system. Using modular program control processor and touch screen display control system, the operation is more stable. Less fixture, easy to change bottle shape, simple debugging and installation, more convenient operation. The core component adopts Yaskawa servo system, which can be equipped with visual positioning system. The machine is stable, with high precision and accurate color registration

Model | Weight | Size | Type |

DM-200 | 1500KG | 1700*1100*2200mm | Automatic |

Details Images

Effect

Product packaging

Company Profile

FAQ