Custom plastic Insert design components injection molding

- Категория: Other Plastic Products >>>

- Поставщик: Shenzhen,Forman,Precision,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.73 $* | 0.14 $* |

| Aug-18-2025 | 0.19 $* | 0.17 $* |

| Jul-18-2025 | 0.48 $* | 0.39 $* |

| Jun-18-2025 | 0.79 $* | 0.61 $* |

| May-18-2025 | 0.75 $* | 0.48 $* |

| Apr-18-2025 | 0.94 $* | 0.98 $* |

| Mar-18-2025 | 0.15 $* | 0.32 $* |

| Feb-18-2025 | 0.49 $* | 0.81 $* |

| Jan-18-2025 | 0.71 $* | 0.84 $* |

Характеристики

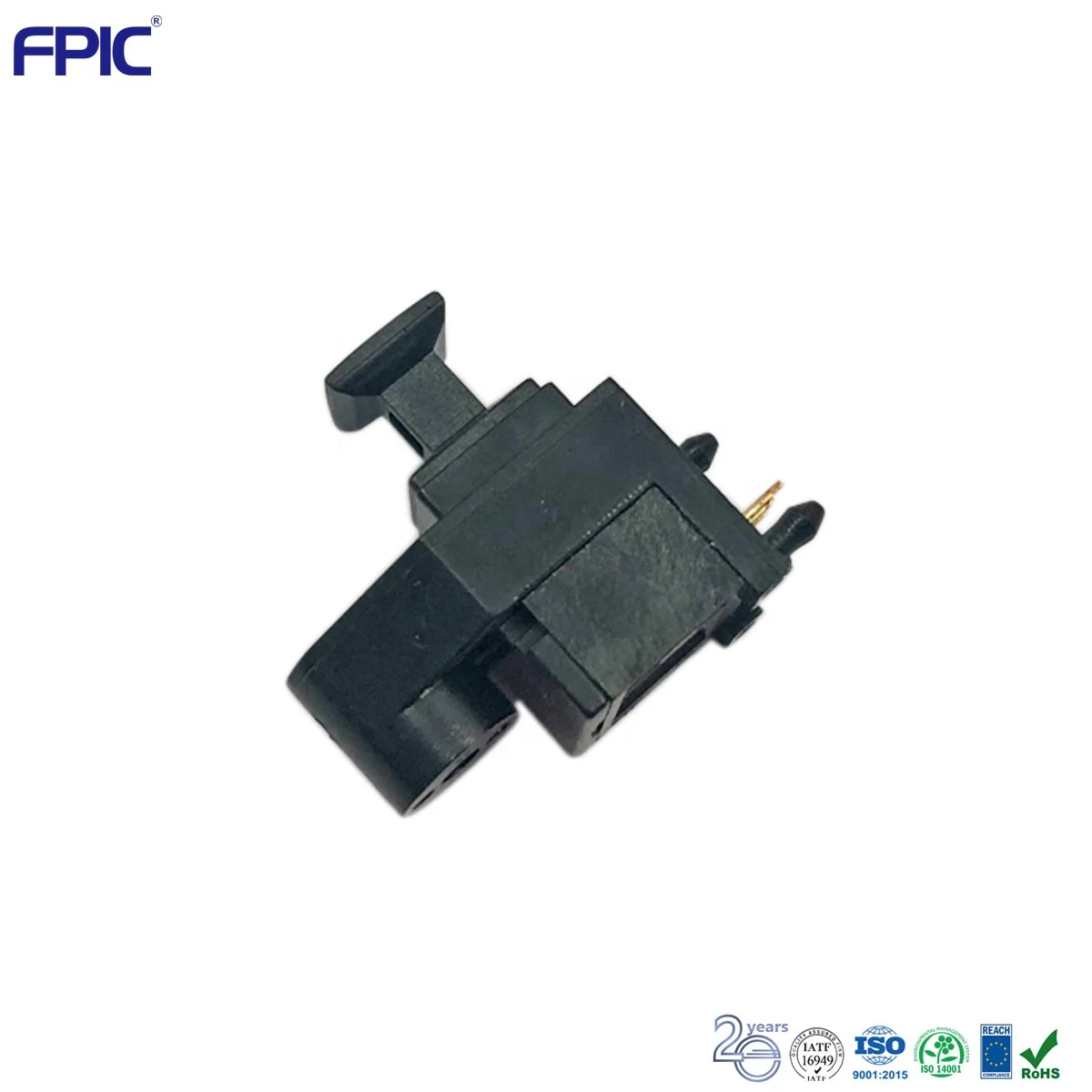

insert molding custom design plastic components injection molding parts

Shenzhen Forman Precision Industry Co., Ltd with over 20 years of OEM fabrication experience in automatic injection, stamping, and assembly process for high-end electronic connectors such as USB, Type C, Automotive Components like terminal, ECU connector, etc., and OEM accessories based on ISO9001, ISO14001, and IATF16949 systems.

Products Description

Flame retardant rating | UL94V-0 | Other Material | Nylon PA66, PA6T, PA9T with glass fiber LCP, PBT, POM, etc. |

Color | Black | Other standard | Halogen-free Compliant |

RoHS Compliant | Yes | Lead time | 7~15 days |

MOQ | 100~500 PCS per lot | Advantages | 1, Both have vertical and horizontal type injection machines. 2, Offering one-stop fabrication services from mold design, manufacture, assembly, and delivery. 3, Short delivery time, but quick response. 4, Professional in various material. 5, Strong R&D support, and quality assurance. |

Insert Molding Injection Parts

Comparing the traditional injection services, insert molding offers a better solution to fix the metal part into the plastic product with better stable performance to improve its lifetime and function.

By now, we have 10 sets of 55 Ton injection molding machines and each equips with a CCD to implement 100% inspection assurance

and automatic fabrication capacity.

And Forman promises all our plastic materials are new and no recycled material will be used, welcome your audit and feel free to send us an inquiry for a reference price.

By now, we have 10 sets of 55 Ton injection molding machines and each equips with a CCD to implement 100% inspection assurance

and automatic fabrication capacity.

And Forman promises all our plastic materials are new and no recycled material will be used, welcome your audit and feel free to send us an inquiry for a reference price.

Looking forward to hearing from you!

Manufacturing Technique

About Forman

Overview

Shenzhen Forman Precision Industry Co., Ltd establishes in 1999, from the beginning, we have been focusing on the development, production, and marketing services for precise components, like plastic injection and metal stamping parts, heat sink, electronic connectors. In recent years, we received more and more auto components' orders, mainly from Germany, Italy, France, America, Mexico, and other countries. Until the end of 2020, the plant covers over 10 thousand square meters, our total investment capital is almost USD10 million, and the annual sales amount is higher than USD15 million.

By the philosophy of “Focus on Customer, Contributor Based, and Always Going All Out”, Forman has established a long-term cooperation relationship with many world-famous companies.There is no doubt that the capability of quality controlling, super flexible delivery, and continuous cost optimization can lead a long-term development, we look forward to working together with you for mutual development and benefits.

Production Area

Factory Strength

Forman has been attaching importance to talent team building and the average industry experience of our technical and managerial personnelis over ten years. On the strength of good management, through the normative operation procedure, based on the ERP, ISO9001, ISO14000, and IATF16949 systems, our company has always been keeping in a good and healthy operation condition.

Nowadays, Forman has its own mold-making, plastic injection, metal stamping, and components assembly workshops. Here we can design and make the tooling for auto-injection and progressive stamping. Meanwhile, develop and produce custom plastic injection parts, metal stamping parts, different auto components, and connectors. In order to make higher precision and quality products, we have imported various precise equipment like Seibu and Sodick slow-feeding wire-cutting equipment, Fanuc and Nissei injection facilities, Kyori and Yamada punch. And the machines in our assembly workshop were designed and installed by our team, which can automatically finish the assembly, inspection, and package for stable quality and high productivity.

Nowadays, Forman has its own mold-making, plastic injection, metal stamping, and components assembly workshops. Here we can design and make the tooling for auto-injection and progressive stamping. Meanwhile, develop and produce custom plastic injection parts, metal stamping parts, different auto components, and connectors. In order to make higher precision and quality products, we have imported various precise equipment like Seibu and Sodick slow-feeding wire-cutting equipment, Fanuc and Nissei injection facilities, Kyori and Yamada punch. And the machines in our assembly workshop were designed and installed by our team, which can automatically finish the assembly, inspection, and package for stable quality and high productivity.

Quality Management

Quality Assurance

Forman clearly understands the quality importance for a company, therefore, every aspect from product designing, producing, to inspecting has been paid attention to.We verify the material reliability in the designing stage, then control every process will strictly comply with all quality systems for best quality in production. Now, we can finish dimension measuring, hardness testing, tensile strength testing, coat thickness measuring, contact resistance testing, flame retardant testing, and various environment testingin our own laboratory with many excellent brand instruments, like Keyence, Nikon, Fischer, and so on.

Exhibition

FAQ

Q: How long can i receive your quotation?

A: Thank you so much for kind support, and after receiving your drawing, specifications, and detail requirements that our engineer will review the structure and evaluate the cost within 48 hours.

Q: What s your advantaged on injection and stamping services?

A: Firstly, Forman offers fully automatic fabrication services for competitive cost and efficiency productivity. And most of our machines are introduced from aboard with high precision tolerance and dimension.

Q: What will you do when the project is placed to you?

A: It depends on what kinds of project we are dealing with, the automotive one will be different from others. But generally that we will offer you the mold DFM and start the mold manufacture when get your approval. And the first sample will be offered within 5 weeks then send for FAI testing, we will send you the sample and testing report when its qualified.

Kindly send us an inquiry ↓ to ask for more detailed information, thank you so much.