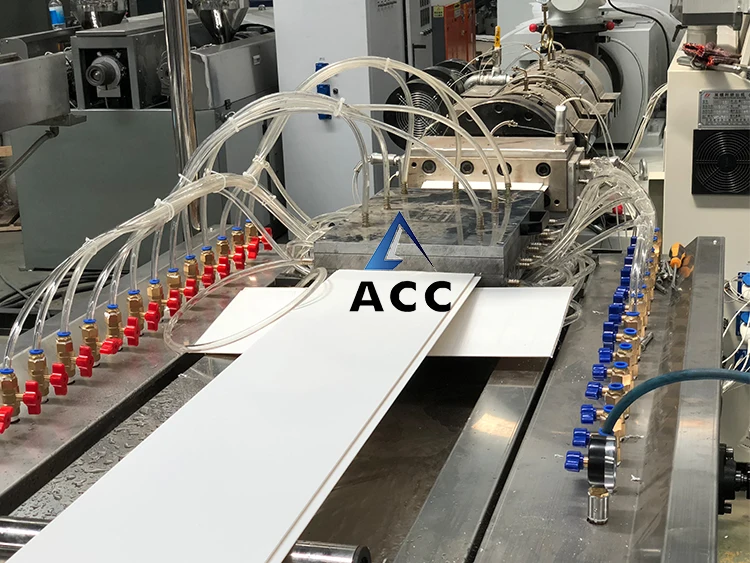

Машина для потолка ПВХ/машина потолочных панелей из производства ПВХ декоративной производственной

- Категория: Building Material Machinery >>>

- Поставщик: Suzhou,ACC,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 47600.79 $* | 49980.77 $* |

| Aug-15-2025 | 47200.4 $* | 49560.8 $* |

| Jul-15-2025 | 39600.93 $* | 41580.66 $* |

| Jun-15-2025 | 46400.74 $* | 48720.11 $* |

| May-15-2025 | 40400.4 $* | 42420.86 $* |

| Apr-15-2025 | 45600.77 $* | 47880.75 $* |

| Mar-15-2025 | 45200.66 $* | 47460.21 $* |

| Feb-15-2025 | 44800.78 $* | 47040.35 $* |

| Jan-15-2025 | 44400.64 $* | 46620.47 $* |

Характеристики

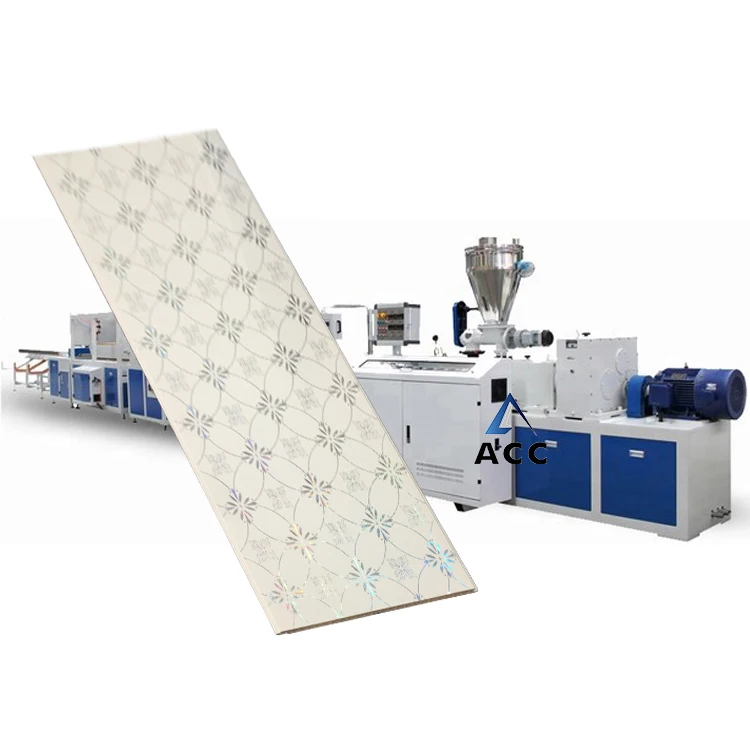

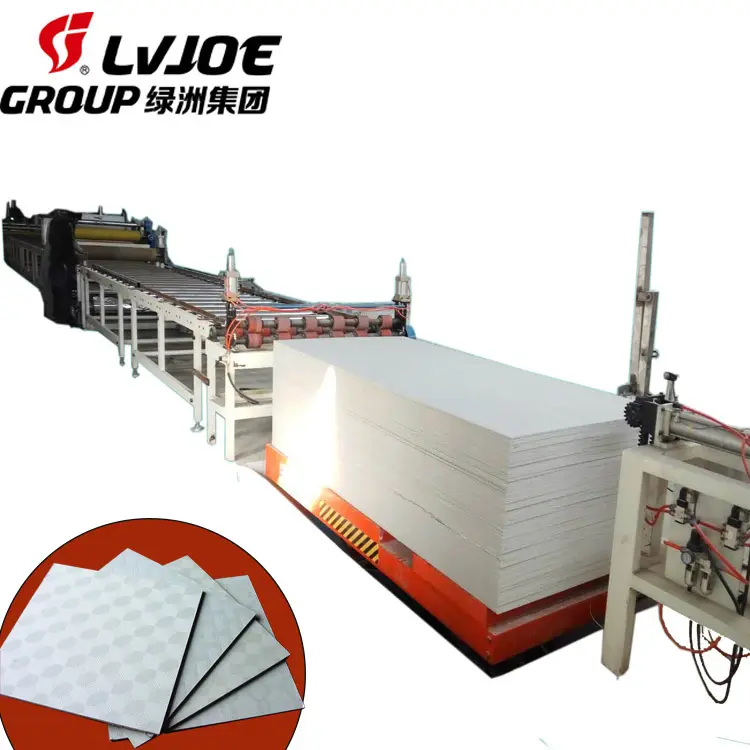

PVC Ceiling Machine/PVC Ceiling Board Machine/PVC Ceiling Panel Making Machine

Our machine can make all kinds of PVC ceiling panel machines.

Raw material: PVC power+ Additives.

Capacity: 120~180 kg/h (Depends on cable trunking size)

Ceiling panel size: 185mm, 200mm, 250mm, 300mm, 380mm, 400mm, 500mm, 600mm etc.

No. | Equipment name | Qty |

1 | Screw loading machine | 1 set |

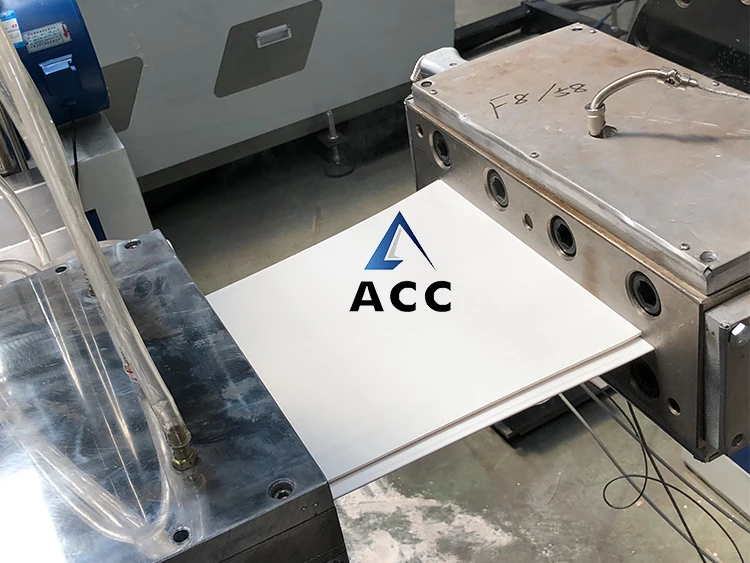

2 | SJSZ-55/110 Double screw extruder | 1set |

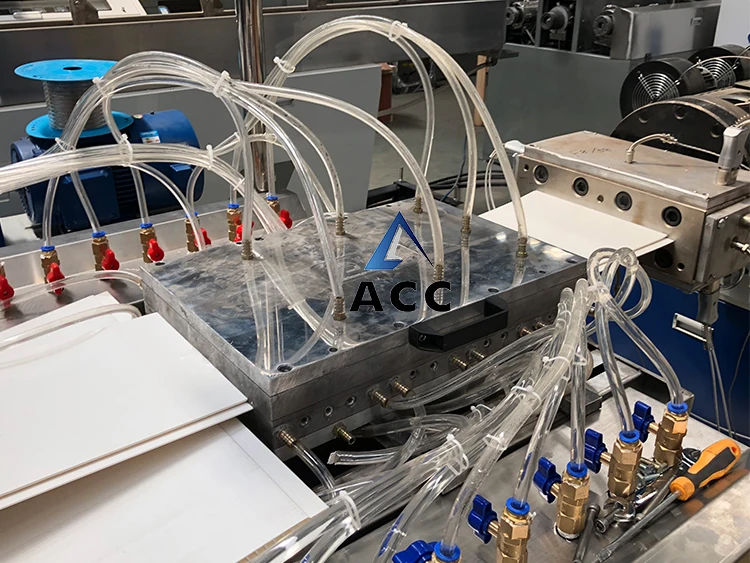

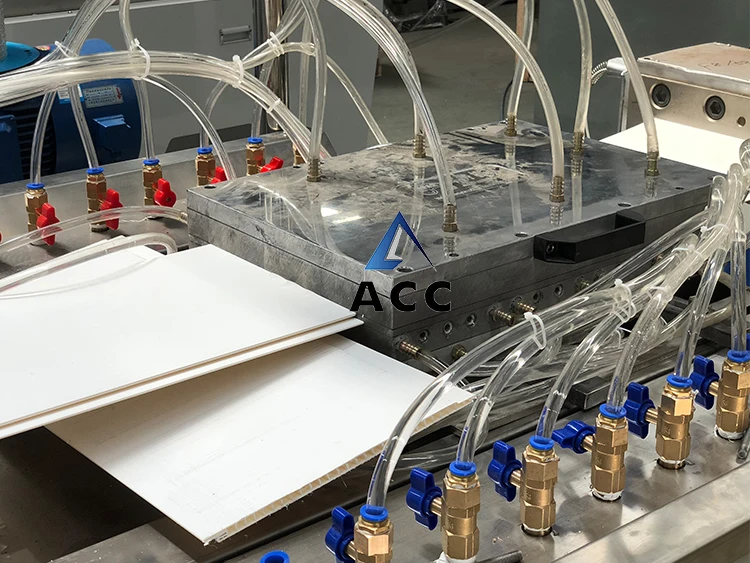

3 | Vacuum calibration tank | 1set |

4 | Haul off machine | 1set |

5 | Cutting machine | 1set |

6 | Stacker | 1set |

7 | PVC ceiling panel mold | 1set |

our service

1. We not only provide machines but also offer technical guide and market evaluate.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

Introduction of PVC ceiling machine:

PVC ceiling machine is used to produce PVC ceiling panel, PVC wall panel with width normally from 150mm to 600mm with different section shape and height. the surface of PVC ceiling panel can be treated by double color roller printing & coated with UV lacquer, or by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

Our Advantages in PVC ceiling machine:

* with Infrared tracking device, benefit for product shape control, suitable benefit for seamless edge PVC ceiling panel

* extruder flange adopts hinged type, convenient for changing filtration net, reduce time for changing net.

cutter adopts rolling blade, reduce dust collection and material waste.

* speed controlled by inverter, saving power and easy to adjust speed

* extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting

* easy and convenient for operation and maintain

* low power consumption: lowest total production line consumption 25kw/hour

* economical price, suitable for large scale investment.

Process of PVC ceiling production line:

Mixer → extrusion → surface treatment (including three types: two color printing, hot stamping, and lamination)

According to our formula(main raw material is PVC resin and caco3), raw materials are mixed in the mixer and tranported to the extruder. Through the PVC ceiling extrusion line, panel forming. It you adopt hot stamping and lamination, after extrusion line,your product is finished, But if you adopt two color printing, you can print it offline in the printing machine.

PVC ceiling machine is used to produce PVC ceiling panel, PVC wall panel with width normally from 150mm to 600mm with different section shape and height. the surface of PVC ceiling panel can be treated by double color roller printing & coated with UV lacquer, or by hot stamping printing, or by lamination, which can make marble, wooden design on surface of product.

Our Advantages in PVC ceiling machine:

* with Infrared tracking device, benefit for product shape control, suitable benefit for seamless edge PVC ceiling panel

* extruder flange adopts hinged type, convenient for changing filtration net, reduce time for changing net.

cutter adopts rolling blade, reduce dust collection and material waste.

* speed controlled by inverter, saving power and easy to adjust speed

* extruder temperature controlled by Omron intelligent controller, temperature fluctuation self adjusting

* easy and convenient for operation and maintain

* low power consumption: lowest total production line consumption 25kw/hour

* economical price, suitable for large scale investment.

Process of PVC ceiling production line:

Mixer → extrusion → surface treatment (including three types: two color printing, hot stamping, and lamination)

According to our formula(main raw material is PVC resin and caco3), raw materials are mixed in the mixer and tranported to the extruder. Through the PVC ceiling extrusion line, panel forming. It you adopt hot stamping and lamination, after extrusion line,your product is finished, But if you adopt two color printing, you can print it offline in the printing machine.

Q1: If I need more information, how to contact you?

A: Send me your demands, we will send back detailed machine specifications with working video.

Q2: How to buy your machine?

A: We send detailed machine quotation to you, if you are satisfied, we will make PROFORMA INVOICE for you.

Payment terms: T/T, L/C, TRADE ASSURANCE

Q3: What about the machine warranty?

A: In some countries, we have agent. We have one-year warranty.

Q4: How can I believe your factory and company?

A: You are welcomed to ask authority agency to visit our factory and machine, we are real factory.

Q5: Do you have other service?

We can send engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Q6: Where is your factory located?

Our factory is located in Zhangjiagang city which is nearby Shanghai port, about 2.5 hours car driving. If you want to visit our factory, we can come to pick you up.

A: Send me your demands, we will send back detailed machine specifications with working video.

Q2: How to buy your machine?

A: We send detailed machine quotation to you, if you are satisfied, we will make PROFORMA INVOICE for you.

Payment terms: T/T, L/C, TRADE ASSURANCE

Q3: What about the machine warranty?

A: In some countries, we have agent. We have one-year warranty.

Q4: How can I believe your factory and company?

A: You are welcomed to ask authority agency to visit our factory and machine, we are real factory.

Q5: Do you have other service?

We can send engineer to your factory to install the machine and offer training. Each year, if we have machine technical improvements, we will inform customer.

Q6: Where is your factory located?

Our factory is located in Zhangjiagang city which is nearby Shanghai port, about 2.5 hours car driving. If you want to visit our factory, we can come to pick you up.