Длительный срок службы станок для сварки проволочной сетки производственная линия

- Категория: Wire Mesh Making Machines >>>

- Поставщик: Fine,Fasteners,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 214200.6 $* | 224910.36 $* |

| Aug-20-2025 | 212400.75 $* | 223020.23 $* |

| Jul-20-2025 | 178200.69 $* | 187110.49 $* |

| Jun-20-2025 | 208800.1 $* | 219240.1 $* |

| May-20-2025 | 181800.33 $* | 190890.46 $* |

| Apr-20-2025 | 205200.74 $* | 215460.72 $* |

| Mar-20-2025 | 203400.61 $* | 213570.96 $* |

| Feb-20-2025 | 201600.61 $* | 211680.94 $* |

| Jan-20-2025 | 199800.61 $* | 209790.88 $* |

Характеристики

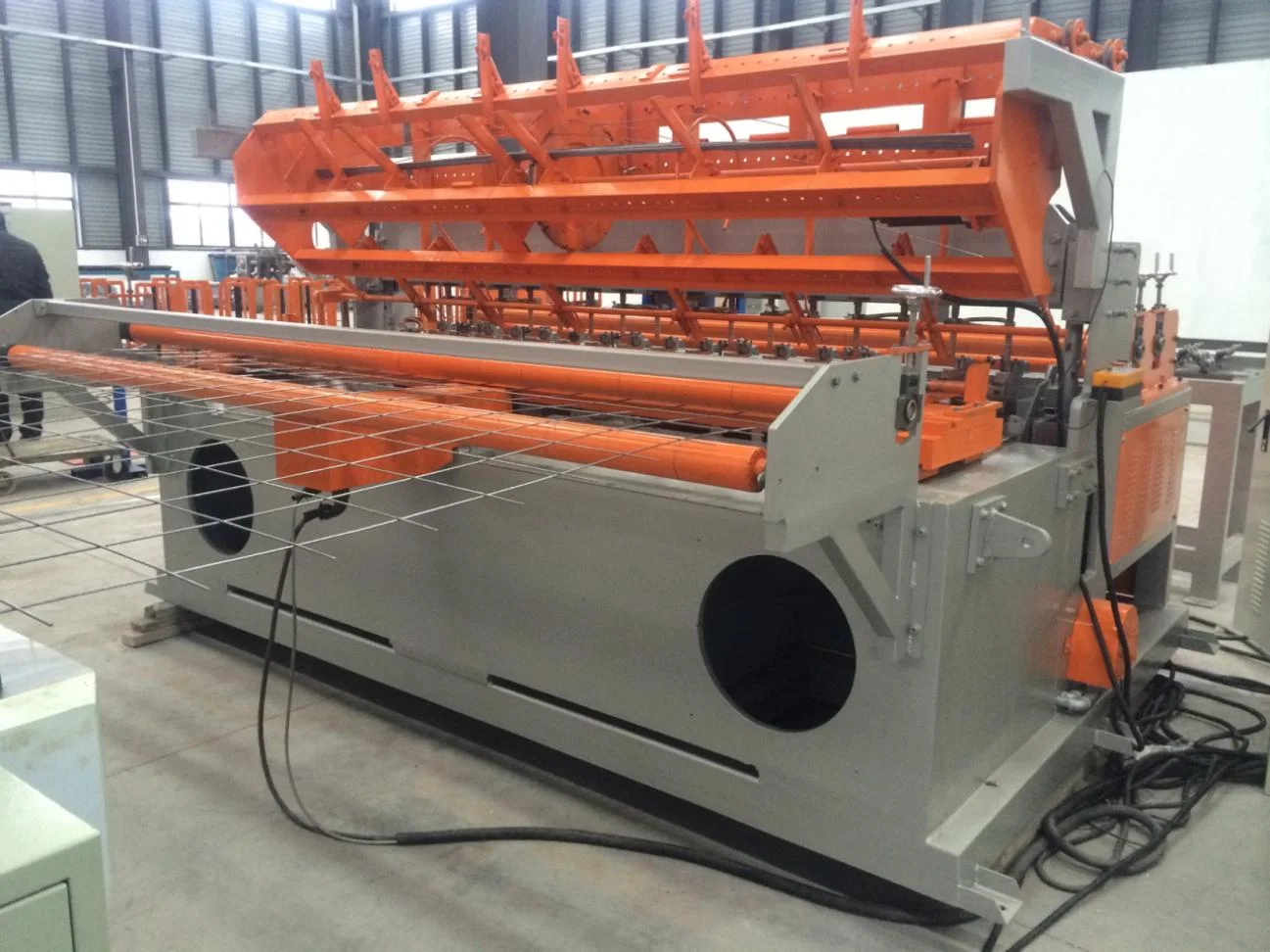

Full Automatic Wire Mesh Welding Line

(wire dia. Φ2.5– Φ5,line wire and cross wire are feed in coil)

Product Description

NO. | Name | Q'ty |

1 | Wire pay-off | 50 |

2 | Full set of line wire from coil (line wire feeding system+ accumulator+ feeder) | 1 |

3 | Cross wire feeding system (cross wire from pre-cutl) | 1 |

4 | Welded wire mesh machine 2.5m with trimmer Mini. Mesh opening: 50*50mm Line wire off roll, cross wire pre-cut, 13 transformers | 1 |

5 | Mesh cutting machine | 1 |

6.1 | Mesh collecting table | 1 |

6.2 | Mesh conveyor system | 1 |

7 | Mesh recoiling machine | 1 |

8 | Full line controlling system | 1 |

9 | wire straightening & cutting machine | 2 |

Specification

1. wire pay-off

The wire pay-off is composed of a chassis, a pay-off shaft seat and a pay-off shaft. The wire pay-off is used to hold the longitudinal rib coil. It has the function of passive rotation and discharge. As long as the inner hole of the coil is put on the wire pay-off, it can be used. Inside and outside diameter of discharge tray: 425×800mm, carrying 160kg.

2.Line wire straightening device

The line wire straightening is composed of oblique straightening before storage and straightening after storage, and is used for straightening after line wire laying.

It is easy for adjusting the wire straightening. straightening units for line wire.

Wire diameter: Ø 2.5mm - Ø 5mm.

It is easy for adjusting the wire straightening. straightening units for line wire.

Wire diameter: Ø 2.5mm - Ø 5mm.

3.Line wire feeding system

The line wire feeding system is composed of a bracket, a roller, a pneumatic mechanism, a driving motor and a transmission device, and is used to send the line wire to the storage buffer zone after straightening.

The line wire get through into the first straightening system, there is line wire broken detective here will stop the machine if the wire is broken, and machine can start work again after the machine start manually again.

The line wire get through into the first straightening system, there is line wire broken detective here will stop the machine if the wire is broken, and machine can start work again after the machine start manually again.

4. Line wire accumulator (Line wire pulling station with loop/line wire balancing system)

Line wire accumulator: Ø 2.5mm - Ø 5mm. CNC automatic feeding and adjusting

Each set can be controlled separately.

Emergency stop switch, keep personnel and equipment away from damage.

All pneumatic parts of the accumulator uses branded systems for easy replacement and maintenance.

All steel structures of the accumulator is hardened using the heat treatment technical.

Each set can be controlled separately.

Emergency stop switch, keep personnel and equipment away from damage.

All pneumatic parts of the accumulator uses branded systems for easy replacement and maintenance.

All steel structures of the accumulator is hardened using the heat treatment technical.

5.Welding mesh machine

Wire mesh welder with step less adjustable cross and line wire pitch, the line wire space is adjusted by hand; the cross wire space is adjusted by the electrical controlling cabinet.

The welding system is designed for smooth and ribbed wire

The welding system is designed for smooth and ribbed wire

item | value |

Condition | New |

Machine Type | Wire Mesh Welding Machine |

Video outgoing-inspection | Provided |

Machinery Test Report | Provided |

Marketing Type | New Product 2020 |

Warranty of core components | 1 Year |

Core Components | Alarm lock |

Wire Diameter (mm) | 2.5mm - 6mm |

Production Capacity | 55~70 strokes/min |

Place of Origin | China |

Anhui | |

Brand Name | FFI |

Model Number | FFI-Automatic Wire Mesh Welding Line |

Weight (KG) | 25000 |

Power (kW) | 88 |

Key Selling Points | High Productivity |

Warranty | 1 Year |

Online support, Video technical support, Field installation, commissioning and training, Field maintenance and repair service | |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Local Service Location | None |

Applicable Industries | Manufacturing Plant, Construction works |

Showroom Location | UAE, Algeria, Malaysia, Egypt, Thailand |

Product name | Automatic Electric Welded Wire Mesh Making Machine Factory in China |

Application | Industry, agriculture, breeding, construction, transportation, mining |

Panel max length | 6000mm |

Panel max width | 2400mm |

Line wire spacing | 100mm |

welder point | 24points |

Cross wire spacing | 50mm,freely spacing |

Feeding | In Coils |

Max. welding speed | 55-70m/min. |

Automatic | Full automatic |

6.Cross wire feeding system

The cross wire feeding system mainly puts the fixed-length sheared and pre-cut cross wire into the feeding system, and the magnetic cylinder of the magnetic cylinder feeding device rotates to feed, and the quantity of each feeding can be adjusted by adjusting the number of magnets. It is then fed to the mesh welding machine by a spinning wheel. It consists of frame,feeding system,magnetic cylinder feeding device, motor reducer driving mechanism, pneumatic device and other devices.

7.Mesh cutting machine

Occupy area: 2.8m×1m, height is 1.6m, designed weight is 2750kg

Cut off the welded mesh into mesh panel

Cut width: 3000mm

Power: 5.5kw

Cut off the welded mesh into mesh panel

Cut width: 3000mm

Power: 5.5kw

8. Mesh stacking (Mesh blanking and convey equipment)

The main function of the automatic mesh stacking is to support the webs in the conveyance after the welding is completed, and the blanks that have been cut to a fixed length are superimposed, and after reaching a certain height, they are transported out by themselves.

9.Mesh coiling machine

Max width:2500mm

Max length:30m

Max length:30m

10.Controlling system

1 units of servo control system

CNC & Display unit from Simens or HUICHUAN

Other electrical component from Schneider

The language of the control in English language and with computer

CNC & Display unit from Simens or HUICHUAN

Other electrical component from Schneider

The language of the control in English language and with computer

Wire straightening and cutting machine

Packing & Delivery

Plywood Case with Pallet

Company Profile

Fine Fasteners Industry Co.,Ltd (FFI) has been a super manufacturer and exporter of nails and the related machines such as all types of wire drawing machine, nail making machine, wire collating machine, plastic and paper tape machine, thread rolling machine.Up to now our customers are spread in Europe, Asia, Africa, South Africa, Middle East and other countries & regions.

We have become a long-term partner for many nail making and wire making factories and helped a number of nail and wire making plants establish their own production lines in past years.

With our superior quality, competitive price and professional service, we have gained great approval and satisfaction from customers globally.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.We are sincerely looking forward to working together with you to create a glorious future.

We will continuously stick to the core principle of “Fine person, Fine product and Fine service” and offer the best equipment for customers through never-ending research and development.We are sincerely looking forward to working together with you to create a glorious future.

Customer Photos

Contact Us

Fine Fasteners Industry Co.,Ltd (FFI)

Ariel Yuan (Sales Manager)

Whatsapp: +8613965697589

Tel: 0086-55182620162

Fax: 0086-551-82620162

Email: ariel(at)finefasteners.com

Website: www.finefasteners.com

Whatsapp: +8613965697589

Tel: 0086-55182620162

Fax: 0086-551-82620162

Email: ariel(at)finefasteners.com

Website: www.finefasteners.com