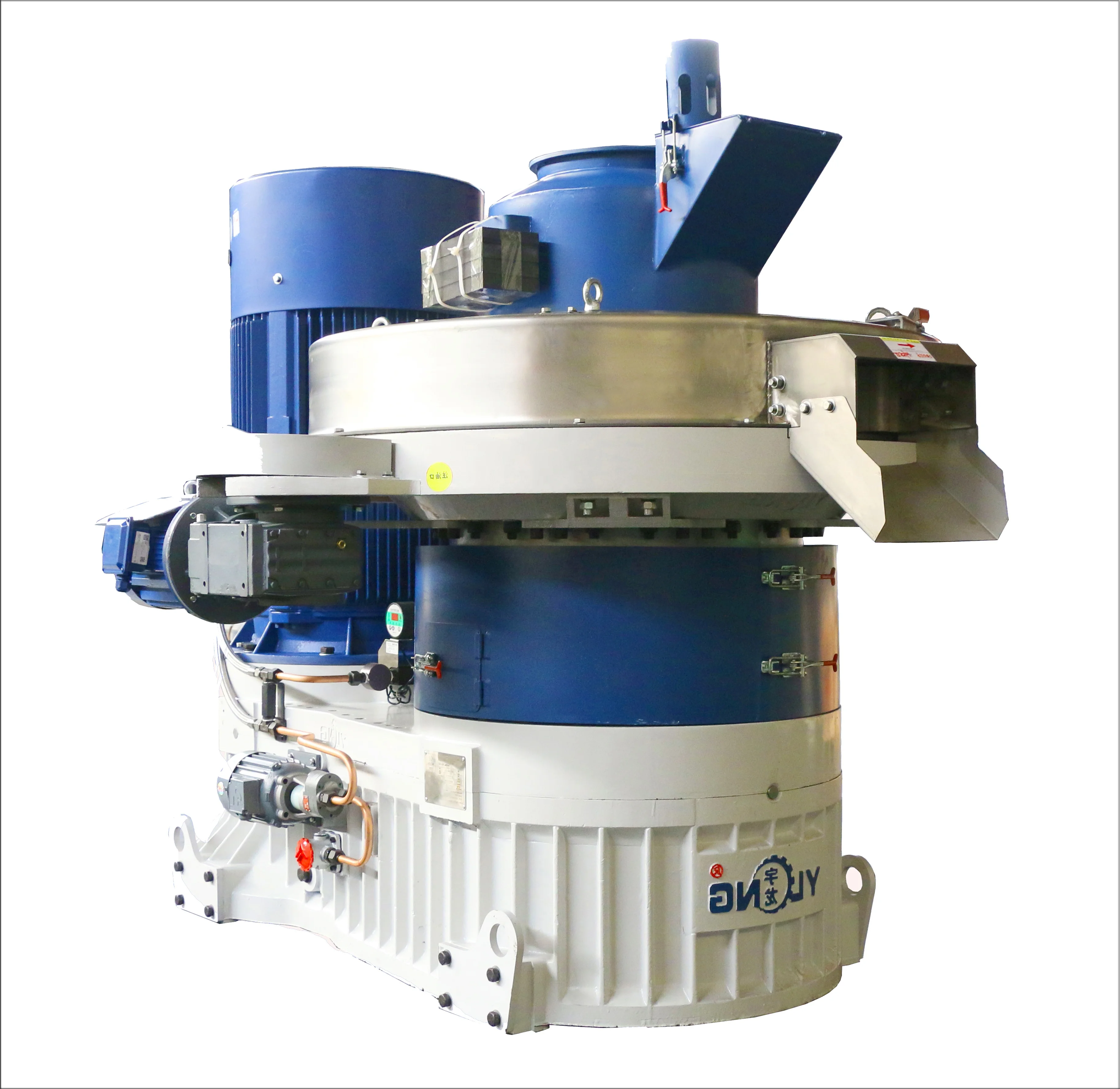

Yulong машина для гранулирования древесины линия выдано восьмого поколения XGJ560 на

- Категория: Wood Pellet Mill >>>

- Поставщик: Shandong,Yulong,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 33320.51 $* | 34986.79 $* |

| Aug-16-2025 | 33040.58 $* | 34692.63 $* |

| Jul-16-2025 | 27720.48 $* | 29106.70 $* |

| Jun-16-2025 | 32480.23 $* | 34104.80 $* |

| May-16-2025 | 28280.21 $* | 29694.2 $* |

| Apr-16-2025 | 31920.24 $* | 33516.50 $* |

| Mar-16-2025 | 31640.82 $* | 33222.86 $* |

| Feb-16-2025 | 31360.88 $* | 32928.98 $* |

| Jan-16-2025 | 31080.41 $* | 32634.84 $* |

Характеристики

Product Details Show

The development history of Yulong Centrifugal High-efficiency Biomass Pellet Machine.

The centrifugal high-efficiency pellet machine originated from Yulong, and has undergone many core technology improvements and functional improvements since its development in 2010. Now updated to the eighth generation products.

Yulong has always mastered the patent and core technology of this product. The appearance of the product is easy to imitate by peers, but the core technology has never been surpassed.

The eighth generation biomass pellet machine.

The new generation of biomass pellet machine is more economical and more durable.

The main advantages of the eighth generation pellet machine:

1. The main motor is changed to a standard flat key motor, and the German standard KTR elastic coupling is adopted with the reducer, which solves the problem of regular lubricating grease for the spline of the seventh generation granulator. Moreover, the replacement cost of KTR elastomer is much lower than the replacement cost after spline damage.

2. The positioning of the spindle frame plate and the spindle has been upgraded and improved, the pin positioning that is not easy to disassemble and easy to wear is removed, and the embedded positioning method of CNC machining is adopted, which is easy to disassemble and not easy to wear.

3. Improvement of kick-out system: The reducer of kick-out plate is replaced by a cycloidal pinwheel reducer to a hard-tooth surface reducer. The rotating components of the kick-out system are completely separated from the kick-out boot (the entire driving operation is outside), which completely solves the problem that the kick-out system is susceptible to high temperature steam. Moreover, in the kick-out boot of the pellet machine, except for the kick-out turntable, the rest of the non-moving parts that can contact the material and steam are all made of stainless steel, which fundamentally solves the corrosion problem of metal materials.

Model | Power(KW) | Size (CM) L*W*H | Capacity(T/H) | Weight(T) |

8th XGJ560 | 132+2.2+0.55+2.2 | 2438*1584*1820 | 1.5-2 | 5.4 |

7th XGJ850 | 250+4+3+0.55+0.55 | 2870*1830*2190 | 3-4 | 13.6 |

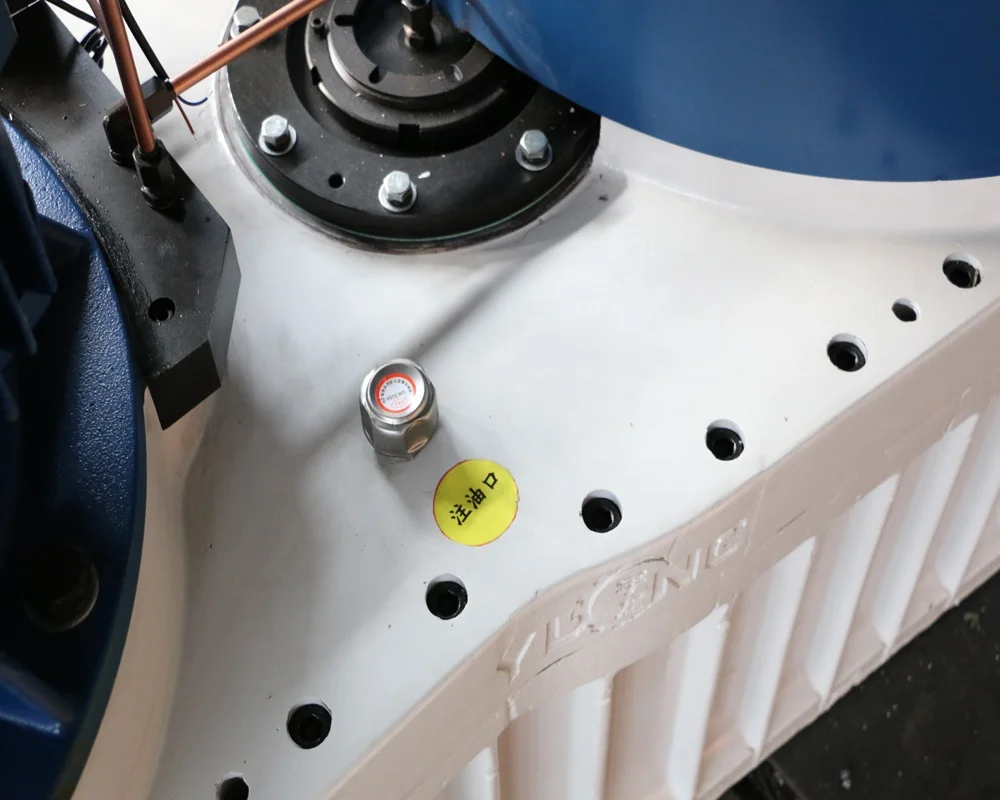

Pelelt Machine Base

Super high machining accuracy

Centrifugal high-efficiency pellet machine ring die

High wear-resistant stainless steel material, vacuum quenching, ultra-high-speed gun drilling, high-quality hole finish. Use full alloy custom drill bits. The mold is wear-resistant and the service life is increased.

High wear-resistant stainless steel material, vacuum quenching, ultra-high-speed gun drilling, high-quality hole finish. Use full alloy custom drill bits. The mold is wear-resistant and the service life is increased.

Roller of centrifugal high-efficiency pellet machine

The surface of the pressure roller adopts robot surfacing welding wear-resistant materials, which greatly improves the life of the roller.

The installation structure of the roller is upgraded to make disassembly and assembly more convenient.

The surface of the pressure roller adopts robot surfacing welding wear-resistant materials, which greatly improves the life of the roller.

The installation structure of the roller is upgraded to make disassembly and assembly more convenient.

The main shaft of the centrifugal high-efficiency pellet machine

The main shaft is thickened by 15%, and a new high-rigidity load-bearing structure is adopted to improve the load-bearing capacity and reduce the failure rate of the pellet machine

Laser Cutting

The cutting surface of the laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the incision is generally controlled within Ra6.5. It adopts computer programming and modular production and installation.

The cutting surface of the laser cutting machine is smooth: the cutting surface has no burrs, and the surface roughness of the incision is generally controlled within Ra6.5. It adopts computer programming and modular production and installation.

Product Testing

Three-coordinate detector, gear monitoring center, spectrometer, metallographic microscope, high-precision hardness tester, to ensure that each accessory meets high-precision and high-hardness assembly standards

Three-coordinate detector, gear monitoring center, spectrometer, metallographic microscope, high-precision hardness tester, to ensure that each accessory meets high-precision and high-hardness assembly standards

Company introduction

Committed to be coming a leader in the biomass energy industry,creating maximum value for customers

Company Profile

Shandong YULONG Machine Co.,Ltd. is a integrated enterprise with product development, design,manufacturing, training,and trade.YULONG was founded in August 1998.

32 patents on its own R&D products

EU CE,SGS certification and son on

Exhibition

Indonesia Exhibition

Bulgaria Exhibition

Malaysia Exhibition

Guangzhou Exhibition

Changchun Exhibition

Beijing Exhibition

Spain Exhibition

Guangzhou Exhibition

Poland Exhibition

Customer Vist

FAQ

Pellet line

Wood pellet production line in Vietnam

(Annual capacity 100,000T)

(Annual capacity 100,000T)

Technological process:

Crushing -> Pre-grinding -> Drying -> Fine grinding -> Pelletizing -> Cooling -> Packing

Tailand Pellet line

Capacity:9-12t/h

Tailand Pellet line

Capacity:5-6t/h

Malysia Pellet Line

Capacity:10-12t/h

Malysia Pellet Line

Capacity:15-18t/h

China Pellet Line

Capacity:6-9t/h

Vietnam Pellet line

Capacity:18-20t/h

Похожие товары

Тракторная мельница для древесных гранул PTO на продажу

US $1200-$1385

8 мм листья огня древесины гранулы машина

US $1999-$5499

Хорошая цена, удобная машина для производства гранул клевера

US $600.00-$900.00