Автоматическая полировальная машина для ножей из нержавеющей стали Sun Glory проекта под

- Категория: Станок для полировки металла >>>

- Поставщик: Guangzhou,Shangguan,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.77 $* | 0.13 $* |

| Aug-16-2025 | 0.48 $* | 0.40 $* |

| Jul-16-2025 | 0.34 $* | 0.48 $* |

| Jun-16-2025 | 0.65 $* | 0.29 $* |

| May-16-2025 | 0.21 $* | 0.81 $* |

| Apr-16-2025 | 0.12 $* | 0.10 $* |

| Mar-16-2025 | 0.82 $* | 0.12 $* |

| Feb-16-2025 | 0.89 $* | 0.7 $* |

| Jan-16-2025 | 0.30 $* | 0.11 $* |

Характеристики

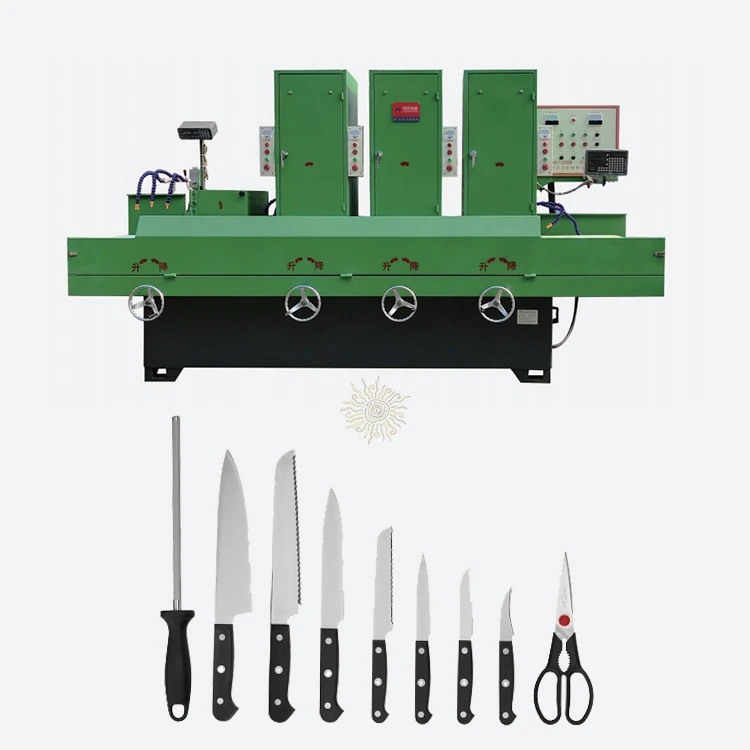

Sun Glory automatic stainless steel knife buffing machine for turnkey project

--- A-Z Complete Turn-key Project Provided

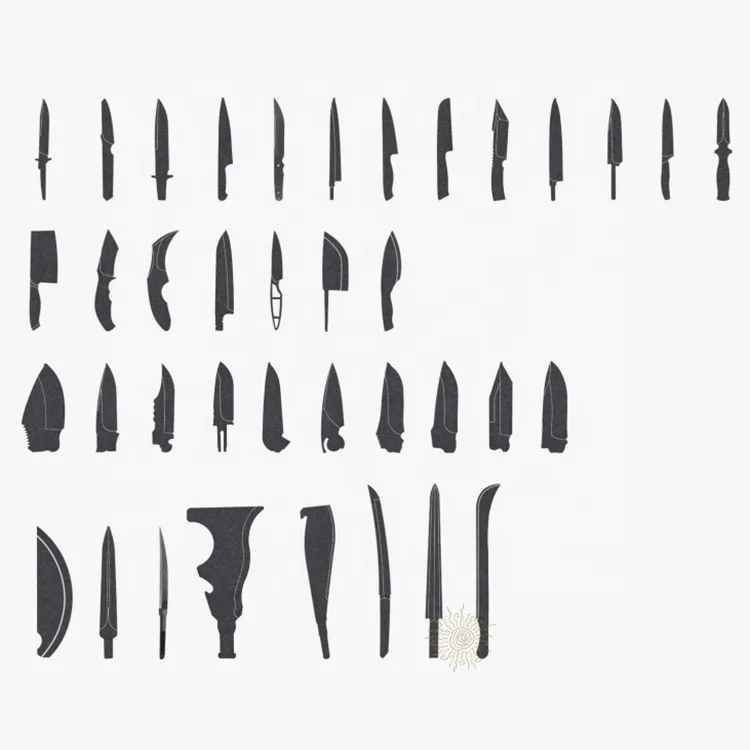

Applicable to surface of various stamping parts, kitchen knives and scissors, automobiles brake disks, various knife blades, knife handle, various metal products.

Around 4 to 6 times faster than manual polishing/buffing.

Parameters

---------------

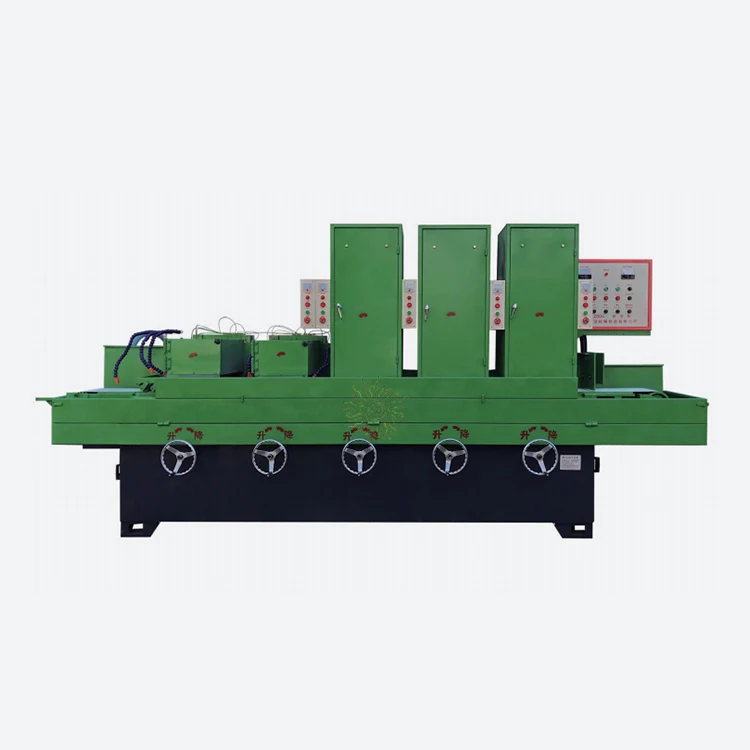

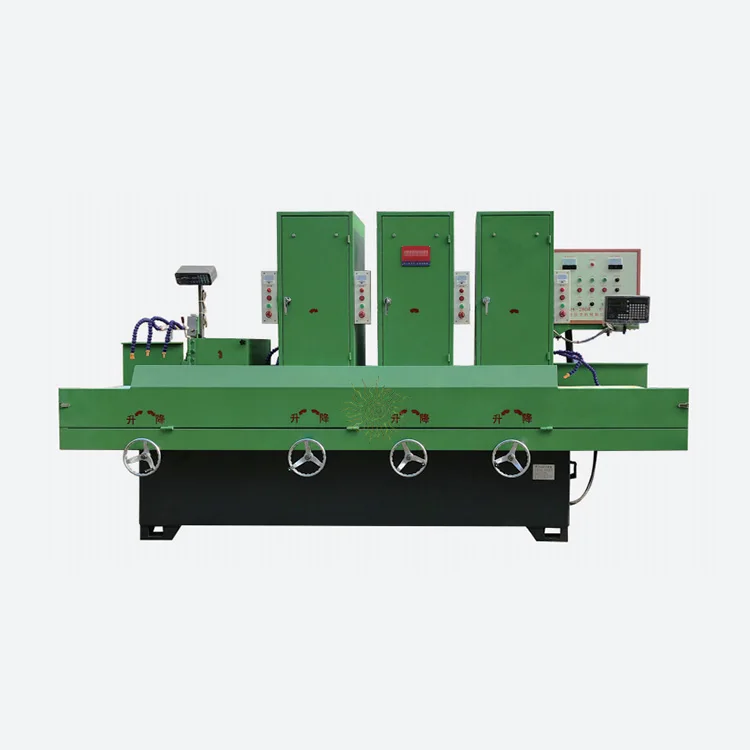

| Item | GH-2804P | GH-2852P |

| Main motor power | 3*7.5KW | 3*7.5KW |

| Grinding wheel rotate velocity | 1*7.5KW | 2*7.5KW |

| Deliver belt continuously variable motor | 0.75KW | 1.5KW |

| Max. grinding width | 270mm | |

| Max. grinding height | 80mm | |

| Scope of bleed pressure | 0.4-0.6Mpa | |

Advantages

The main shaft box and worktable are high-strength castings. Worktable and machine rack processed by the CNC gantry machining center, ensure absolute parallelism between worktable and grinding wheels. The elastic of abrasive belt is automatically controlled by the air cylinder.

Machine equipped with two abrasive belt grinding heads and a nylon abrasive grinding head, which can complete three processes of roughen, refine and smooth process by one time, shortening process turnaround time and improving production efficiency. The surface roughness polish by the machine up to 0.8mm.

End products

-----------------

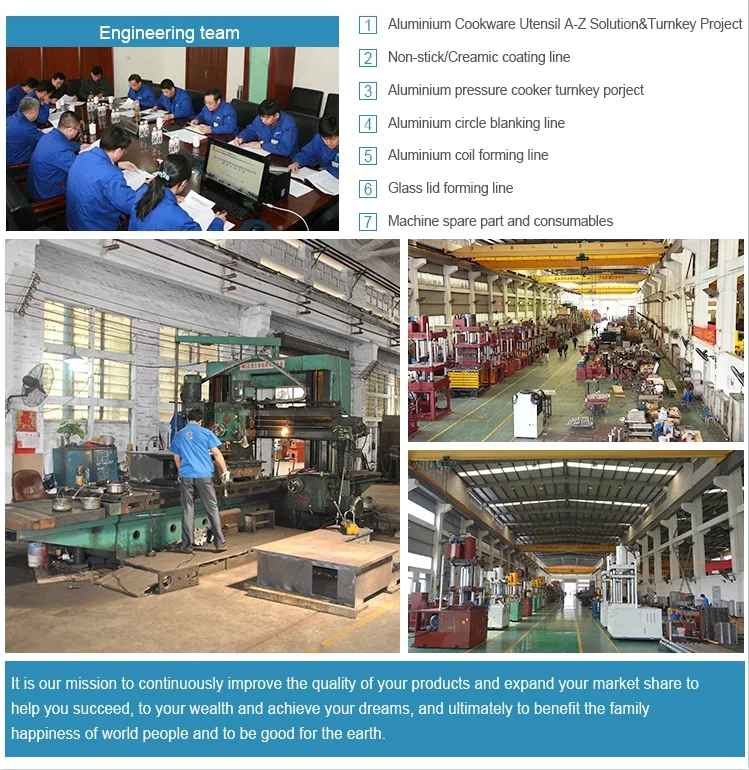

About us

------------

Successful Projects

---------------------------

Services

-----------

Pre-sale Service

1. Popular design, new trend information sharing.

2. Return of investment analysis.

3. A-Z solution flow chat design.

4. Production process design and feasibility study.

5. Machines line arrangement.

In-sale Service

1. Machines and molds quality control during manufacturing and after finish.

2. Independent verification for each process.

After-sale Service

1. Plant layout proof & production line positioning.

2. Production line installation & debugging.

3. Training after shipment in buyer's factory.

4. Annual visit on site.

Upgraded Service

1. Market trend & latest fashion broad casting.

2. Continuous & systematic training for management, maintenance team & operators.

3. Back up for the regular production.

4. Support in new R&D realization.