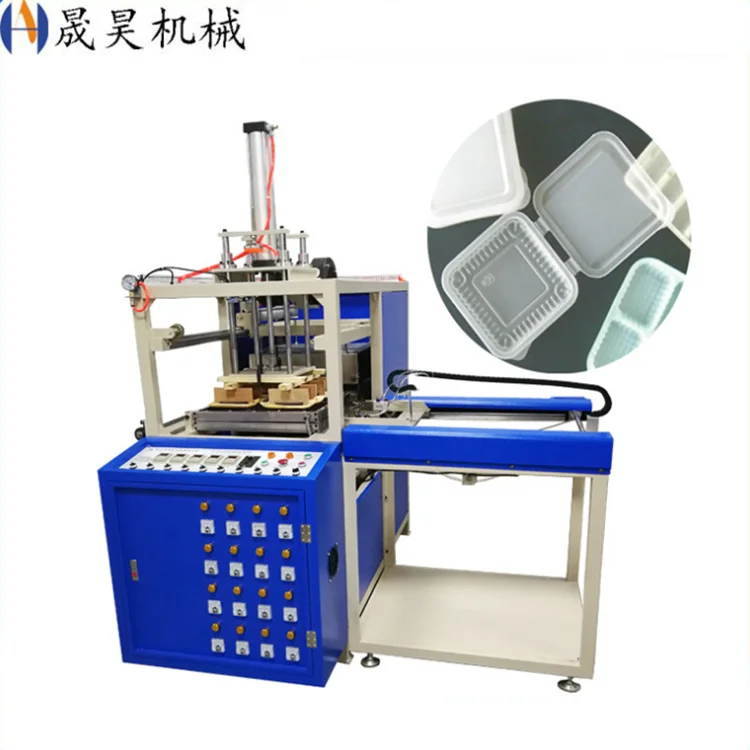

Высокоскоростная блистерная вакуумная формовочная

- Категория: Вакуум-формовочная машина для пластика >>>

- Поставщик: Dongguan,Chenghao,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.39 $* | 0.97 $* |

| Aug-18-2025 | 0.60 $* | 0.47 $* |

| Jul-18-2025 | 0.16 $* | 0.3 $* |

| Jun-18-2025 | 0.36 $* | 0.60 $* |

| May-18-2025 | 0.25 $* | 0.67 $* |

| Apr-18-2025 | 0.0 $* | 0.3 $* |

| Mar-18-2025 | 0.35 $* | 0.69 $* |

| Feb-18-2025 | 0.89 $* | 0.21 $* |

| Jan-18-2025 | 0.92 $* | 0.20 $* |

Характеристики

High speed blister vaccum forming machine

A: characteristics of vacuum molding machine:

1. Control system: the central integrated control system enables continuous blister molding, such as feeding → heating → plasticizing → cooling → film removal → cutting, etc. Imported components ensure the quality and quality of the whole machine;

2, electric furnace control: the electric furnace is made of stainless steel, to avoid similar models made of iron plate under high temperature to produce iron oxide falling on the sheet material, resulting in product scrap;

3. Temperature control system: using far infrared ceramic heating brick, independent control switch, even temperature control, built-in insulation material, reduce heat loss to a low limit, significant energy saving;

4. Air cooling system: equipped with air cooling system fast cooling device, no vibration and afterwind, to speed up production;

5, feeding drive system: servo · frequency conversion technology, electric control puller, powerful power, and the length of the puller is accurate, high-speed operation can still ensure its accuracy and stability, single-head thick piece blister machine can adapt to different raw material processing technology

6. Vibration demoulding: it can be adjusted arbitrarily between 0 and 9 times. The upper mold can protect the formed products from deformation and crack during demoulding.

7. Secondary vacuum: built-in secondary vacuum makes products easier to be formed, reduces rejection rate and improves product quality;

8. Warning system: equipped with product quantity setting device and full-plate alarm device, which is suitable for production statistics of batch products or each roll of film

9. Control mode: semi-automatic operation and manual operation are optional. All the actions can be automatic or manual except loading, discharging and hot furnace movement. Ensure molding quality and improve product quality.

Semi-automatic plastic punching machine simplex semi-automatic plastic machine operation is convenient

Semi-automatic plastic punching machine simplex semi-automatic plastic machine operation is convenient

B: Working process:

Installed mould-plastic sheet or plate clip to clip box - move above the heating furnace to plastic - plastic - plastic softening - - remove the electric furnace heating period is over to another job position to plastic heating, heating at the same time, the original location of the mold and softening plastic seal, vacuum, plastic mold, cooling, mold clinging to blow out air reduce hardening plastic and mold separation - mold - open the clip frame - take out the product

C: Scope of application of vacuum molding machine

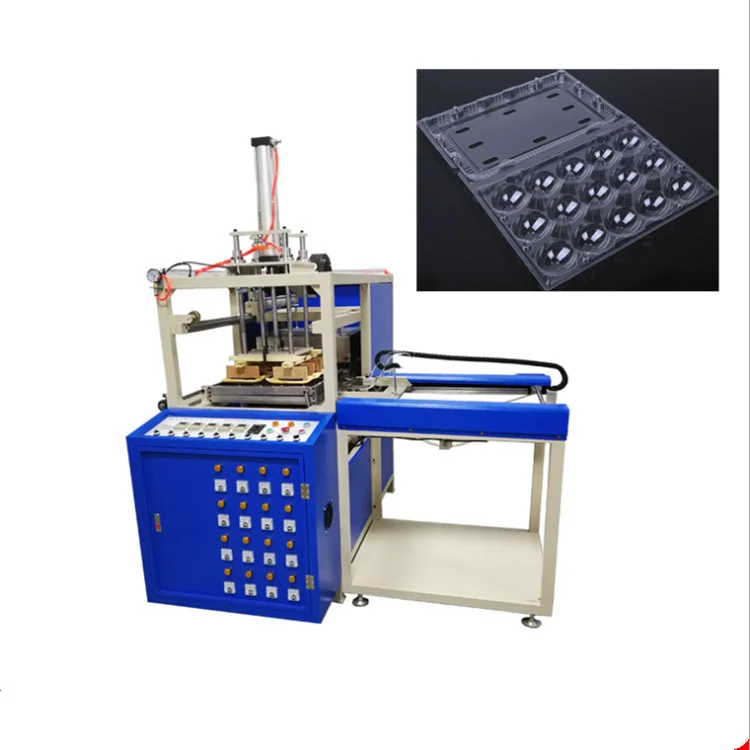

Can be PVC, PE, PP, PS, PET, PETG, ABS and other types of plastic sheet materials into a variety of shape box, widely used in hardware, toys, stationery, tableware, tools, food, electronics, drugs and other packaging or plastic thin-wall products molding.

1. Plastic packaging industry (blister packaging, plastics, batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration);

2. Food packaging industry (disposable fast-food box, fruit tray, biscuit box, egg tray, moon cake packaging tray, cake plastic packaging box);

3. Pharmaceutical industry (pill packaging, pill packaging, oral liquid packaging tray)

4. Plastic packaging tray for cosmetic products and inner packaging tray for cleaning and care products.

The Machine Parameters

| Model | CH-12.5KW-ZDXS |

| Voltage | 380V 3P 50/60HZ |

| Power | 12.5KW |

| Forming Size | 560*610MM |

| Forming Height | 200MM |

| Production speed | 200-300Moulds/H |

| The thickness of the material | 0.2-1.5MM |

| Machine Size | 1800*1200*2000MM |

| Machine Weight | 600KG |

When blister forming machine complete to sample need below to cutting :

Rocker arm cutting machine

30Ton cutting machine

Sample Mould :

Contact:

Name: Alan Wang

Wahtsapp: 008613686820990

Wechat: jiwei1986518 or 13686247603