RCF бесплатно одеяло формы AES (алкалиновый силикат)

- Категория: Other Heat Insulation Materials >>>

- Поставщик: YUTAKA,CORPORATION

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.33 $* | 0.41 $* |

| Aug-19-2025 | 0.12 $* | 0.23 $* |

| Jul-19-2025 | 0.66 $* | 0.89 $* |

| Jun-19-2025 | 0.33 $* | 0.41 $* |

| May-19-2025 | 0.7 $* | 0.69 $* |

| Apr-19-2025 | 0.71 $* | 0.11 $* |

| Mar-19-2025 | 0.67 $* | 0.82 $* |

| Feb-19-2025 | 0.19 $* | 0.17 $* |

| Jan-19-2025 | 0.1 $* | 0.50 $* |

Характеристики

Products Description

BSSR BLANKET

RCF FREE:Blanket Form of AES(Alkaline Earth Silicate) Wool

Light weight, Flexible and Excellent Heat insulation and Heat resistance of AES Wool Blanket

Size of Blank Material :

Thickness : 12.5mm 25mm 50mm

Length X Width : 600X7200 mm 600X3600 mm

Applications :

1. Back-Up insulation for the industrial furnaces (Indusry: steel, nonferrous metals, glass, ceramics, petrochemical,

semiconductors, cement etc.)

2. High temperature sealing material such as ladle lid, duct connecting part etc.

3. External insulation such as boiler, turbine, duct and piping, precision casting shell etc.

4. High temperature gas filtration material, high temperature part sound absorbing material.

5. Noncombustible materials for building.

Light weight, Flexible and Excellent Heat insulation and Heat resistance of AES Wool Blanket

Isowool BSSR Blanket is blanket formed Bio Soluble Fiber (AES wool) featuring light weight, flexible, excellent insulation and

heat resistance

Needle punching is carried out while laminating fibers in a layered manner in the manufacturing process, and the fibers are

entangled intricately and kept in a blanket shape.

heat resistance

Needle punching is carried out while laminating fibers in a layered manner in the manufacturing process, and the fibers are

entangled intricately and kept in a blanket shape.

Size of Blank Material :

Thickness : 12.5mm 25mm 50mm

Length X Width : 600X7200 mm 600X3600 mm

Applications :

1. Back-Up insulation for the industrial furnaces (Indusry: steel, nonferrous metals, glass, ceramics, petrochemical,

semiconductors, cement etc.)

2. High temperature sealing material such as ladle lid, duct connecting part etc.

3. External insulation such as boiler, turbine, duct and piping, precision casting shell etc.

4. High temperature gas filtration material, high temperature part sound absorbing material.

5. Noncombustible materials for building.

Remarks :

・This fibrous material is exempt from the regulations of the International Agency for Research on Cancer (IARC), EU Directive (97/69/EC), and the German Technical Rules for Hazardous Substances (TRGS 905).

Isowool BSSR products are subject to rapid changes in volume (shrinkage) due to their thermal history and chemical composition.

Delivery Form of BSSR BLANKET :

Blank material without any machining will be supplied.

Isowool BSSR products are subject to rapid changes in volume (shrinkage) due to their thermal history and chemical composition.

Delivery Form of BSSR BLANKET :

Blank material without any machining will be supplied.

Product Paramenters

BSSR 1200 BLANKET | ||||

Bulk Density (kg/m³) | 96 | 128 | ||

Heat Resistant Temperature | ℃ | 1200 | ||

Shot Content (%) +212μm | 20 | 20 | ||

Linear Shrinkage (%) | at 1100℃×24hrs | 0.6 | 0.6 | |

Thermal Conductivity (W/(m・K)) JIS A 1412-1 ※Calculation value | 200℃ | 0.06 | 0.05 | |

400℃ | 0.11 | 0.10 | ||

600℃ | 0.20 | 0.18 | ||

800℃ | 0.31 | 0.28 | ||

Chemical Composition(%) | SiO₂ | 73 | ||

CaO+MgO | 22 | |||

Others | 5 | |||

Listed values are measured, it is not a guaranteed value.

Heat resistant temperature is for reference only, and varies depending on the operating conditions.

Company Introduction

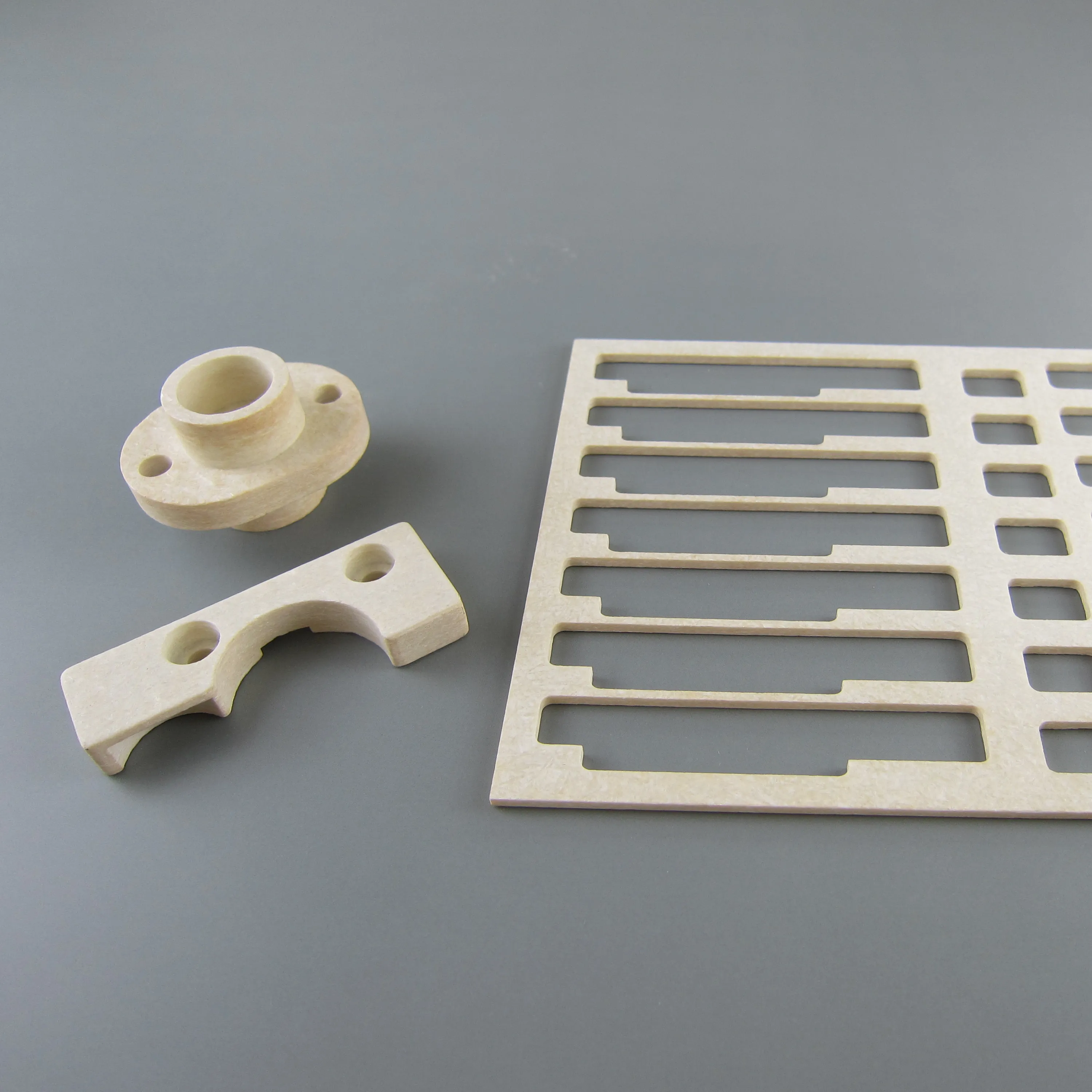

We are experts in manufacturing and supplying plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials products mainly for machinery parts.

We use machine tools such as Machining Centers and NC lathes to process a variety of plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials.

Our product line encompasses a wide range of plastics, ceramics and heat (thermal) insulation materials and we are especially adept at using materials that are difficult to machine including the following ;

1.Heat (thermal) insulation and heat (thermal) resistant materials (rigid heat insulation boards that are generally made of glass fiber, cement and mica as the main raw material)

2.Composite of glass fiber or carbon fiber and plastics (FRP, GFRP and CFRP).

3.Fine ceramics

We use machine tools such as Machining Centers and NC lathes to process a variety of plastics, ceramics and heat(thermal) insulation/heat(thermal) resistant materials.

Our product line encompasses a wide range of plastics, ceramics and heat (thermal) insulation materials and we are especially adept at using materials that are difficult to machine including the following ;

1.Heat (thermal) insulation and heat (thermal) resistant materials (rigid heat insulation boards that are generally made of glass fiber, cement and mica as the main raw material)

2.Composite of glass fiber or carbon fiber and plastics (FRP, GFRP and CFRP).

3.Fine ceramics

Похожие товары

Теплоизоляционный материал изготовлен из цемента и стекловолокна

US $10.00-$100.00

Теплоизоляционная плита, сделано в Японии

US $10.00-$100.00