Трубчатая машина для

- Категория: Textile Finishing Machines >>>

- Поставщик: Dezhou,Deguan,Textile,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 61880.70 $* | 64974.87 $* |

| Aug-17-2025 | 61360.97 $* | 64428.58 $* |

| Jul-17-2025 | 51480.61 $* | 54054.68 $* |

| Jun-17-2025 | 60320.57 $* | 63336.6 $* |

| May-17-2025 | 52520.91 $* | 55146.27 $* |

| Apr-17-2025 | 59280.87 $* | 62244.82 $* |

| Mar-17-2025 | 58760.95 $* | 61698.97 $* |

| Feb-17-2025 | 58240.4 $* | 61152.58 $* |

| Jan-17-2025 | 57720.94 $* | 60606.74 $* |

Характеристики

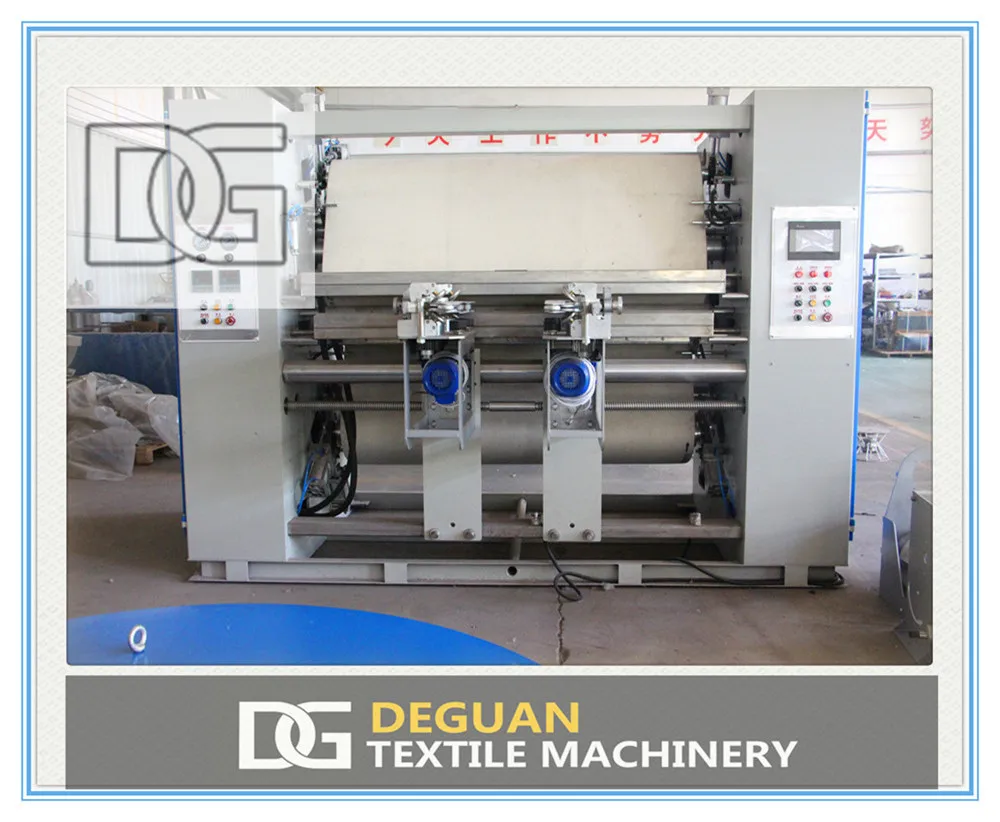

Tubular Compactor

1.\tMethods of Heating: 1.Steam 2. Thermal Oil 3. Recycle Oil

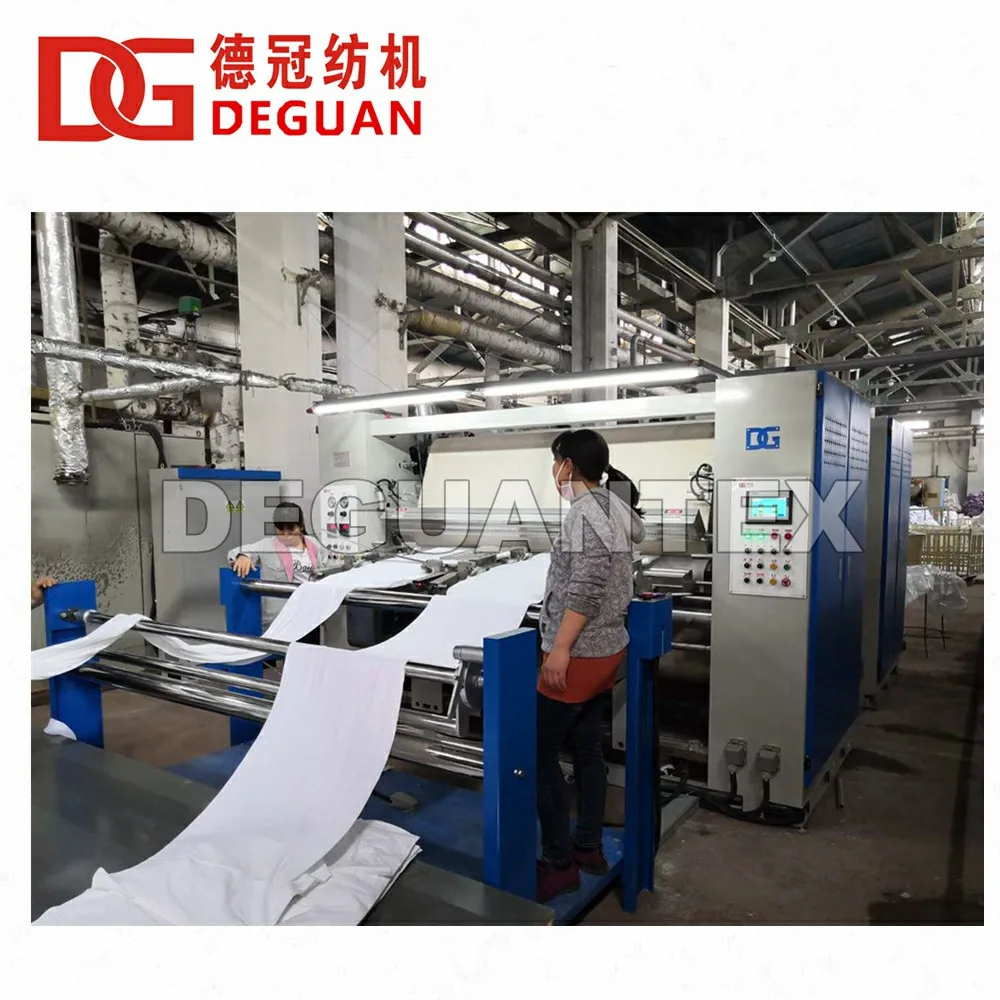

2.\tThis machine is used for tubular cotton knitted fabric and preshrinking process, and the tubular compactor is equipped with 20mm Nomex carpet, magnetic shuttle, hydraulic lifting platform.

3.\tThe temperature of machine could reach 180℃ max based on different heating source.

4.\tOur machine blanket is 20mm thickness, which could resist high temperature and not pollute the fabric. After the process of preshrinking, the fixed size of tubular fabric could be achieved.

5.\tThe width of fabric: 1450 mm Max.

****single pass or double pass

****Standard diameter of Cylinder is 450mm.

Technical Specification | ||

Model | DGYS450 | |

Name | Tubular Fabric Compactor machine | |

Application | Textile-finishing(shrinkage rate:2-5%) | |

Suitable Fabric | Tubular knitted Fabric Pure cotton,wool,blended fabric(cotton content>65%) | |

Main Matching Fabric | Tubular fabric of above 65% cotton content | |

Heat source | Thermal Oil | |

Pre-shrinking type | 20mm Nomex compacting | |

Supporting Plate type | Maglev separated shuttle | |

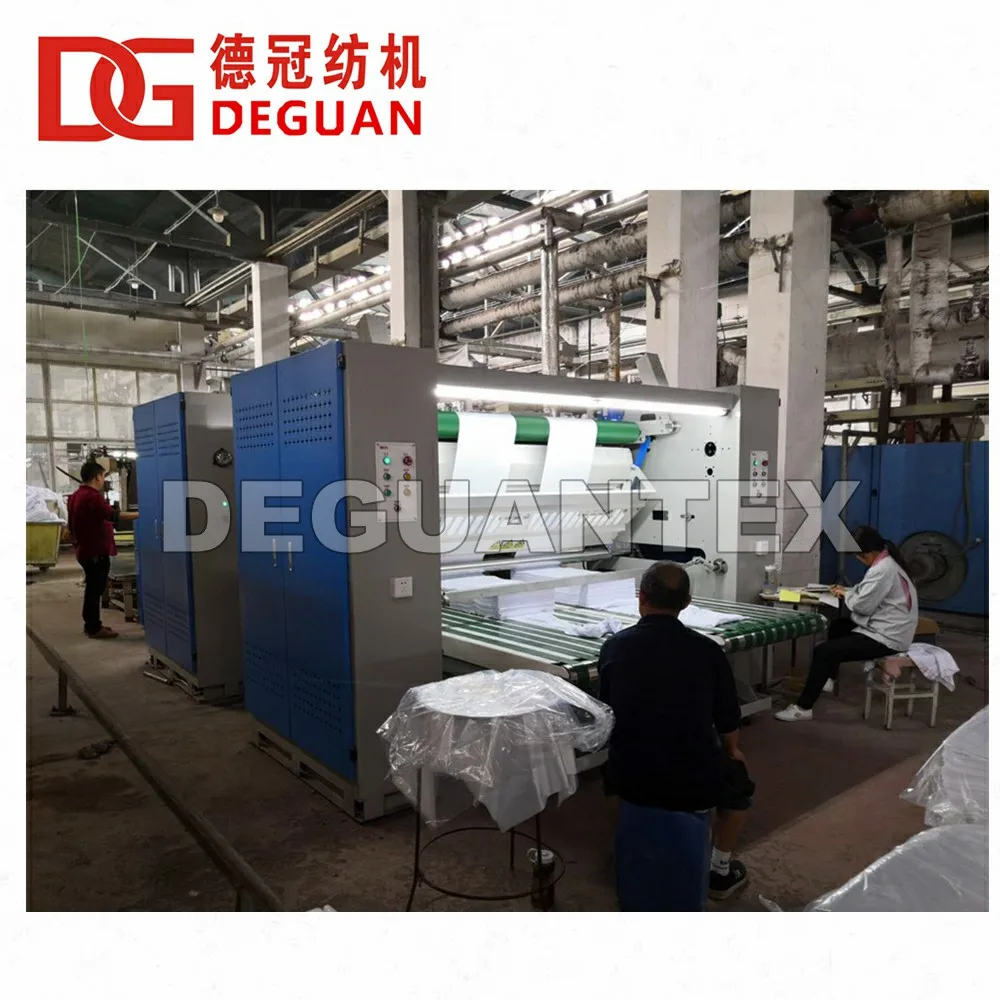

Fabric Outfeed type | Auto precisely plaiter | |

Max fabric width | 1450mm | |

Working speed | 5-30m/min | |

Max temperature of | Electricity, Thermal Oil <180℃,Steam<140℃ | |

Breadth Adjustment type | Semi-automatic | |

Capacity of machine | 10kw | |

Standard machine power supply | 380V/3P/50HZ | |

Control power supply | 220V/24V | |

Compressed air | 0.35-0.6MPa | |

Dimension | 7450mm*2740*2100mm (L*W*H) | |

Parts Details

From the Magnetic Shuttle, you can see the auto entry's operation will be easy to grasp and save your labour, increase the production.

Meanwhile, the sensor could detect the potential broken fabric and stop the entry automatically.

The exit of fabric is equipped with precision folding machine, one button one press will done. We'd like to show you how to operate our tubular compactor when we face to face.

Machine Parts

Name: Magnetic Shuttle

Brand: Deguan

Original:China

High effciency and advanced technology applied, manufactured by our factory.

Main Features

Name: Blanket

Brand: With Nomex materia

Original: China

The blanket made of by imported material and has high ltemperature resistance. Reliable quality and 20mm thickness could last for 10years at least.

Machine Parts

Name: Frame

Brand: Deguan

Original: China

Stainless Steel frame in Tubular Compactor, high quality could make you use this machine without any problem.

Main Features

Name: Precision Folding machine

Brand: Deguan

Original: China

The exit of fabric of Tubular Compactor is Folding mode. Our Precision Folding machine could deal with the tubular fabric in excellent order and easy to collect after processing.

Packaging | ||

Size | 7500mm(L) * 2750mm(W) *2150mm (H) | |

Weight | 4.5 T | |

Packaging Details | Standard Export Package Based on our many years experiences Pallet or Frame | |

Packaging | ||

Size | 7500mm(L) * 2750mm(W) *2150mm (H) | |

Weight | 4.5 T | |

Packaging Details | Wrapping Package Different parts with different package to ensure the perfect status | |