Флексографический стаканчик принтер для печати на бумажниках бумажнике Высокоскоростной автоматический 6 цветов с автоматическим натяжением 2500

- Категория: Flexographic Printers >>>

- Поставщик: Zhejiang,Cidihuakai,Import,And,Export,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 35700.95 $* | 37485.37 $* |

| Aug-20-2025 | 35400.37 $* | 37170.49 $* |

| Jul-20-2025 | 29700.12 $* | 31185.85 $* |

| Jun-20-2025 | 34800.62 $* | 36540.0 $* |

| May-20-2025 | 30300.37 $* | 31815.5 $* |

| Apr-20-2025 | 34200.37 $* | 35910.91 $* |

| Mar-20-2025 | 33900.43 $* | 35595.37 $* |

| Feb-20-2025 | 33600.16 $* | 35280.45 $* |

| Jan-20-2025 | 33300.93 $* | 34965.49 $* |

Характеристики

Supply Ability

Supply Ability: 10 Set/Sets per Month

Packing & Delivery

Packaging Details :film packing and wooden packing ( with flexible wrapping and wooden case.)

Port:Ningbo

Video Description

Products Description

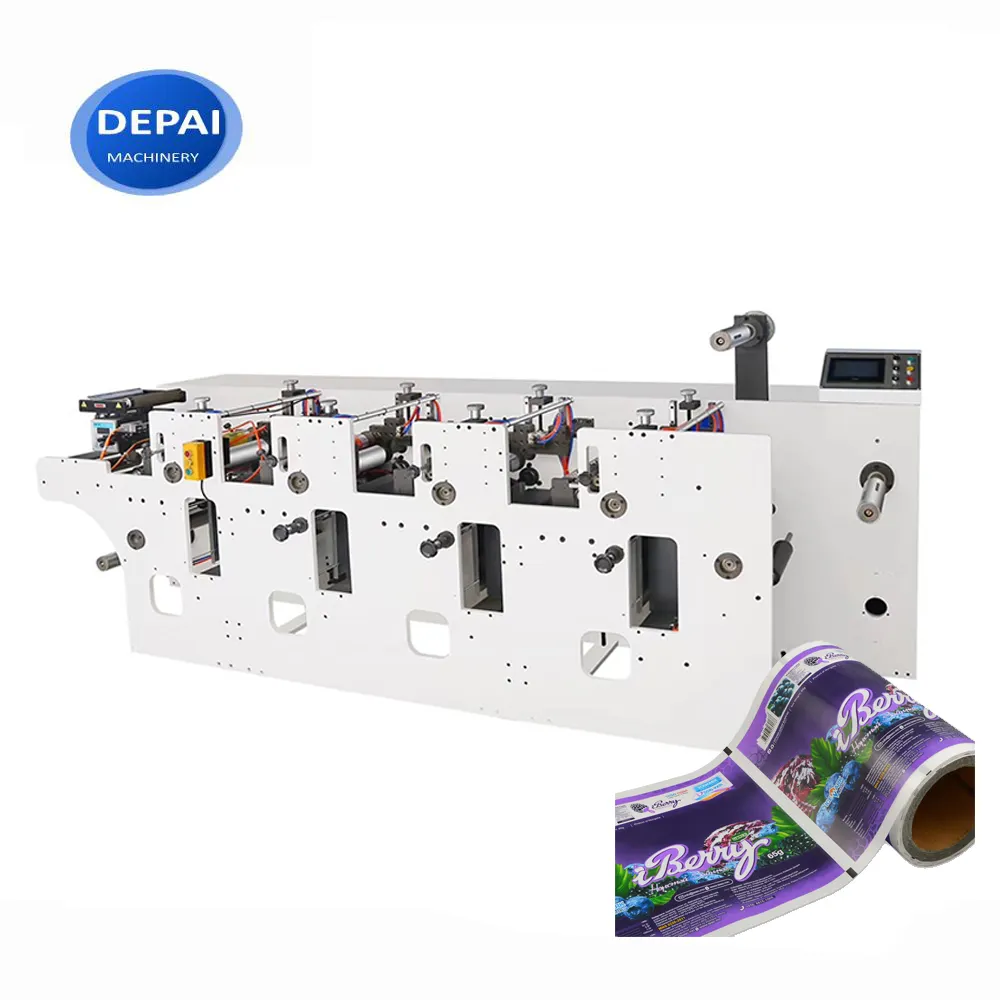

This central impression (central drum)flexographic printing machine is suitable for printing such packing materials as

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food,

supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

paper material between 20--200gsm.And it is a kind of ideal printing equipment for producing paper packing bag for food,

supermarket handbag, non-woven bag, vest bag and clothes bag, etc.

Characteristics:

1) Central impression type printing machine with better color registration. Due to the big drum, the printed material is

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase

the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

supported by the big drum, and greatly improving color registration, especially with extensible materials.

2) All colors printing station drived by the central drum, Less transmission errors because of less gear transmission, increase

the registration precision.

3) Adopting high-quality motor, high-quality inverter, save the electricity, reduce the run fluctuation.

4) The machine is equipped with blower and heater; and the heater employed central temperature control system,

automatic temperature controller, and separated heat source.

5) The use of individual drying oven and cold wind system can effectively prevent the ink adhesion after printing.

6) Roller adopts special steel processing, and through special treatment, greatly reduce the beating range.

7)Printing roller uses static balance and dynamic balance processing, hard anode oxidation treatment, small resistance,

beating small, achieves finally perfect printing effect.

8)Accurate printing effect achieved by special gear transmission device.

9)The printing machine all can choose advance configurations to achieve the high quality, the high-definition effect.

Specification

Type | Flexographic Printer |

After Warranty Service | Video technical support, Online support, Spare parts, Field maintenance and repair service |

Plate Type | Screen Printer |

Usage | Paper Printer, Label Printer, Roll Paper |

Automatic Grade | Automatic |

Color & Page | Multicolor |

Voltage | 380/220V |

Dimensions(L*W*H) | 4500*1600*2500mm |

Weight | 2500Kg |

Print Speed | 100m/min |

Certification | CE/ISO |

Warranty | 1 Year |

Core Components | Bearing, Motor, Pump, Gear, PLC, Gearbox |

Tension | Auto tension |

Material | Paper, film, non woven fabric,pe,opp,napkin |

Plate Type | Letterpress |

Title goes here.

Feeding Material Part

1.Automatic stop machine when break the material. When machine stop, keep tension and avoid the material loose or line deflection.

2.Single unwinding system, equipped with air shaft , EPC and automatic tension control system with magnetic brake. 3.Auto

pneumatic loading&unloading for unwind

4.Roller core diameter: 76mm 5.Discharge maximum diameter: 1000mm

1.Automatic stop machine when break the material. When machine stop, keep tension and avoid the material loose or line deflection.

2.Single unwinding system, equipped with air shaft , EPC and automatic tension control system with magnetic brake. 3.Auto

pneumatic loading&unloading for unwind

4.Roller core diameter: 76mm 5.Discharge maximum diameter: 1000mm

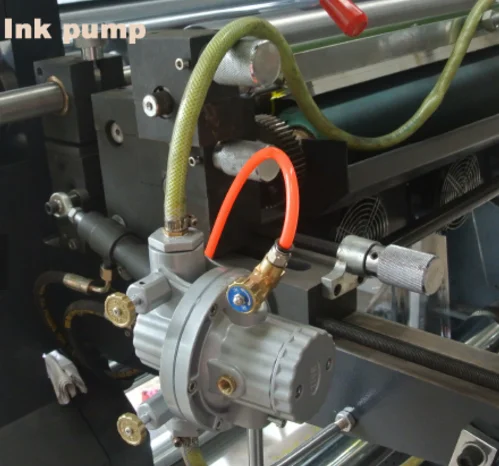

Printing Sections

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade. 2.Plate

roller circumference: 300-800mm.3.Print material: resin plate or rubber plate. 4.Transmission: central drum with big gear drive

the printing station.

5.Printing roller in&out by step motor

1.Printing consists of: central drum, plate roller, ceramic anilox roller, single doctor blade and chamber doctor blade. 2.Plate

roller circumference: 300-800mm.3.Print material: resin plate or rubber plate. 4.Transmission: central drum with big gear drive

the printing station.

5.Printing roller in&out by step motor

Drying System

1.Use hot air drying, intelligent constant temp control.2.Drying units are installed after the printing units, and air volume can

be adjusted by independent damper/panel.

3. The drying system after the printing it is about 30kw.

1.Use hot air drying, intelligent constant temp control.2.Drying units are installed after the printing units, and air volume can

be adjusted by independent damper/panel.

3. The drying system after the printing it is about 30kw.

Rewinding Part

1.Single unwinder system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.2.Roller core

diameter: 76mm

3.Discharge maximum diameter: 1000mm

4.Different material and weight have different design. (Like the picture show which is big roller friction for rewinding, special

in paper rewind)

1.Single unwinder system, equipped with air shaft , EPC and automatic tension control system with magnetic brake.2.Roller core

diameter: 76mm

3.Discharge maximum diameter: 1000mm

4.Different material and weight have different design. (Like the picture show which is big roller friction for rewinding, special

in paper rewind)

FAQ

1.How to start an order with us ?

1. Inquiry -Email Wechat/whatapp 24 hours available for have your requirements

2. Solution offer - Best quotation based on your production capacity ,invest plan ,budget ect.

3. Customized -High-end customized according your local market requirement.

4. Preparation before placing order -Share us your factory layout ,we will design it the machine space ,air ,power ,electric

accordingly ,invite you come to visit our machinery factory or our model customer’s factory to understand details .

5. Confirm the order -With the advanced payment for starting machine prodcution .

2.How to check the quality of the machine you ordered and the guarantee ?

1. Production process -We will show online meeting at our factory working time for machinery procss from the raw material

inspection to machine assembly,8 hours running the machine for testing is most important

2. Quality control -Each part is marked with the source code of the supplier, and the real name of each production link is

assessed,12 months Warranty,We would express the free replacement parts during the warranty date.

3. Delivery- Packing according to international shipping, railway or air Shipping tracking standard ,Tracking information will bekeep updated by our side .

3.How about the Installation and training when the machine arrive your factory ?

1. Installation -Engineer Schedule confirmed 7 days before machinery arrival ,7-10days for installation depend on the machine operation difficulty .

2. Training -Due to virus,buyercannot dispatch technician to install machine in buyer's factory.But will provide machine

operating manual and machine disassemble video for reference.If buyer meet some problems during installation,will have engineer online,but the buyer require to download Wechat apply for a account as other foreign app doesn't work in China.

3. Cost of Installation & Training :You shoud cover our engineer's visa, air tickets,SIM card, hotel, food, and also their

salary 80USD one day per person.

4.How to build a long-term partnership between us ?

1.Feedback - Your sincere feedback is the most effective reference for the continuous improvement of our service Deep cooperation

2..Deep cooperation :We provide a complete set of raw materials matching with the equipment with our experience to save your timeand cost .

1. Inquiry -Email Wechat/whatapp 24 hours available for have your requirements

2. Solution offer - Best quotation based on your production capacity ,invest plan ,budget ect.

3. Customized -High-end customized according your local market requirement.

4. Preparation before placing order -Share us your factory layout ,we will design it the machine space ,air ,power ,electric

accordingly ,invite you come to visit our machinery factory or our model customer’s factory to understand details .

5. Confirm the order -With the advanced payment for starting machine prodcution .

2.How to check the quality of the machine you ordered and the guarantee ?

1. Production process -We will show online meeting at our factory working time for machinery procss from the raw material

inspection to machine assembly,8 hours running the machine for testing is most important

2. Quality control -Each part is marked with the source code of the supplier, and the real name of each production link is

assessed,12 months Warranty,We would express the free replacement parts during the warranty date.

3. Delivery- Packing according to international shipping, railway or air Shipping tracking standard ,Tracking information will bekeep updated by our side .

3.How about the Installation and training when the machine arrive your factory ?

1. Installation -Engineer Schedule confirmed 7 days before machinery arrival ,7-10days for installation depend on the machine operation difficulty .

2. Training -Due to virus,buyercannot dispatch technician to install machine in buyer's factory.But will provide machine

operating manual and machine disassemble video for reference.If buyer meet some problems during installation,will have engineer online,but the buyer require to download Wechat apply for a account as other foreign app doesn't work in China.

3. Cost of Installation & Training :You shoud cover our engineer's visa, air tickets,SIM card, hotel, food, and also their

salary 80USD one day per person.

4.How to build a long-term partnership between us ?

1.Feedback - Your sincere feedback is the most effective reference for the continuous improvement of our service Deep cooperation

2..Deep cooperation :We provide a complete set of raw materials matching with the equipment with our experience to save your timeand cost .

Похожие товары

Печатная машина для пластиковых потолочных панелей из ПВХ

US $20000-$30000

Запасные части для флексографской печатной машины

US $1000-$10000