Непрерывный пиролиз кокосовых скорлупов машина для производства древесного угля Машина Для Брикетирования

- Категория: Carbonization Stove >>>

- Поставщик: Gongyi,Sanjin,Charcoal,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.7 $* | 0.23 $* |

| Aug-17-2025 | 0.67 $* | 0.5 $* |

| Jul-17-2025 | 0.38 $* | 0.7 $* |

| Jun-17-2025 | 0.38 $* | 0.96 $* |

| May-17-2025 | 0.67 $* | 0.77 $* |

| Apr-17-2025 | 0.87 $* | 0.82 $* |

| Mar-17-2025 | 0.2 $* | 0.75 $* |

| Feb-17-2025 | 0.82 $* | 0.84 $* |

| Jan-17-2025 | 0.49 $* | 0.90 $* |

Характеристики

Product Application

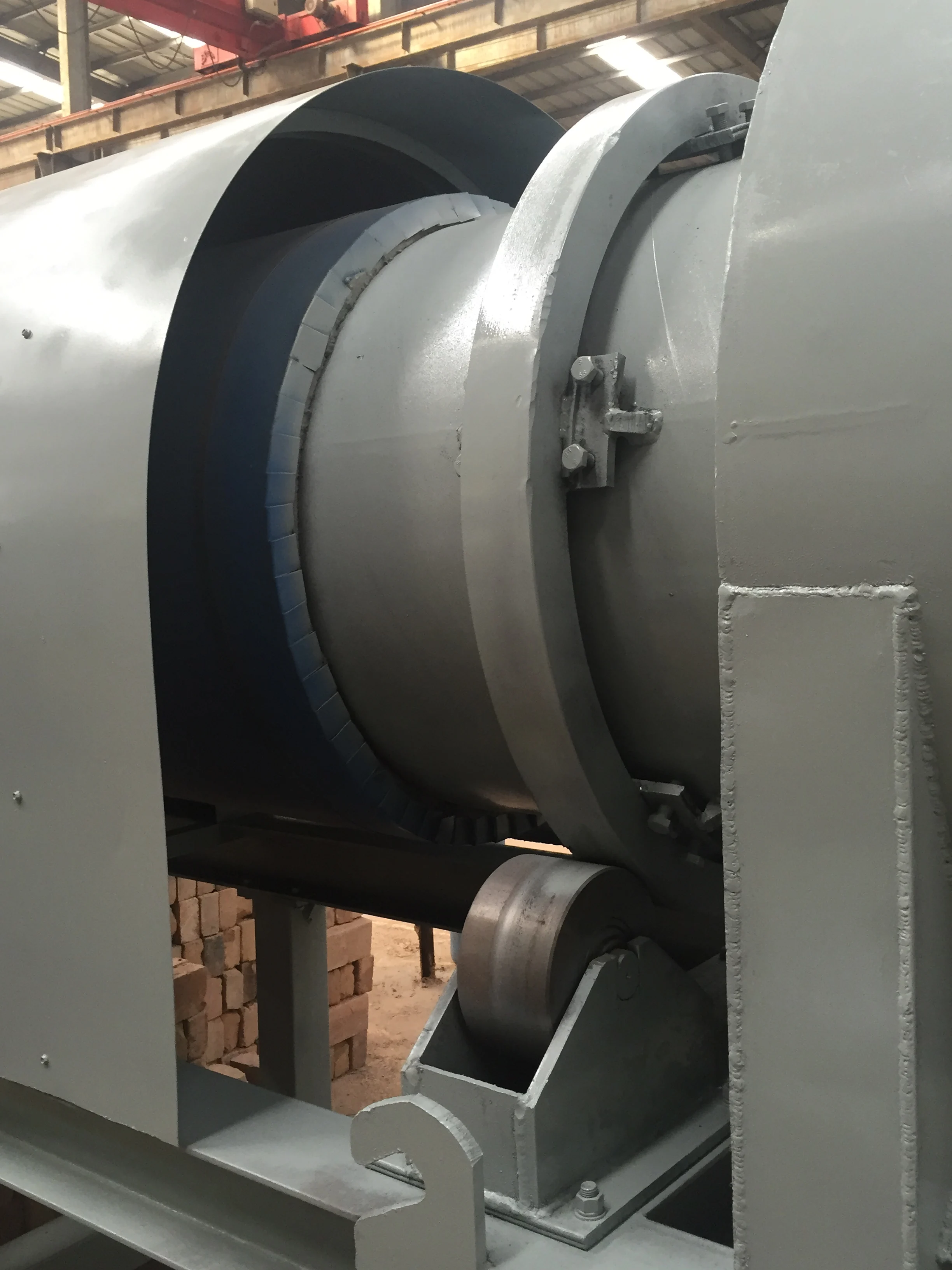

The continuous carbonization furnace is mainly used for the carbonization of biomass materials. The equipment is still using the principle of gasification carbonization and adopts advanced smoke-free environmental carbonization process:The whole set of equipment consists of gasification system (liquefied gas gasification machine), purification system (spray tower, cyclone dust removal, water cooling, oil water separator, fine filter) and control system (control cabinet). The whole carbonization process is automated production, automated operation.

Different from the energy-saving and environmentally-friendly continuous carbonization machine, it has two significant advantages: First, the main machine has a large volume, high carbonization rate, and strong production capacity, and can be produce 0.3-0.8 tons of carbonized products per hour;

Second, the cost is low and the practicability is strong, which satisfies the objective requirements of the initial small entrepreneurs' investment and small benefits. The carbonization machine is a carbonized wood material such as wood chips, rice husks, peanut shells, plant straws, bamboo chips, coconut shells, palm shells, bark, etc. (volumes of less than 10 cm in size) are subjected to dry distillation under high temperature conditions in the furnace, Ideal equipment for oxygenation and high carbonization rates.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .

Machine Detail

Type: LTJ-1000

Total Power: 3+3+7.5+3kw

Capacity: 700-1000kg/h

diameter*length(MM):1000*1000

Primary heating unit:12

The host base:10*1.45*1m

Cooling discharging(MM):1200*2900

The feed temperature:350-450 degree

The feed size:less than 3cm

The feed moisture:less than 15%

Large volume, high carbonization rate, strong production capacity

Mahcine Detail

Type: LTJ-1200

Total Power: 3+3+15+3kw

Capacity: 1000-1500kg/h

diameter*length(MM):1000*1000

Primary heating unit:14

The host base:10*1.45*1m

Cooling discharging(MM):1200*2900

The feed temperature:350-450 degree

The feed size:less than 3cm

The feed moisture:less than 15%

Large volume, high carbonization rate, strong production capacity

In nearly 20 years of development, our factory together industry elite, professional and technical, fall in love."Sanjin machinery" from a single charcoal machine equipment development to the series of power plant equipment, have three series more than 30 varieties of mechanical products.I plant strong technical force, advanced production technology and equipment, perfect testing and test methods, excellent technical and after-sales service, continuous new product technology improvement, make our products always in the leading level at home and abroad, and won the national patents 10.Has been exported to Britain, Russia, Malaysia, Indonesia, Vietnam and other countries and regions, favored by customers at home and abroad and praise, has a higher market share in domestic and foreign markets.