Оборудование для автоматического непрерывного карбонизации древесного

- Категория: Carbonization Stove >>>

- Поставщик: Henan Lantian Machinery Manufacture Co., Ltd.Henan Lantian Machinery Manufacture Co., Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 3585994.43 $* | 3765294.66 $* |

| Aug-20-2025 | 3555859.71 $* | 3733652.5 $* |

| Jul-20-2025 | 2983306.38 $* | 3132471.61 $* |

| Jun-20-2025 | 3495590.13 $* | 3670370.90 $* |

| May-20-2025 | 3043574.90 $* | 3195753.35 $* |

| Apr-20-2025 | 3435322.96 $* | 3607088.75 $* |

| Mar-20-2025 | 3405187.58 $* | 3575446.52 $* |

| Feb-20-2025 | 3375053.11 $* | 3543806.78 $* |

| Jan-20-2025 | 3344918.71 $* | 3512164.80 $* |

Характеристики

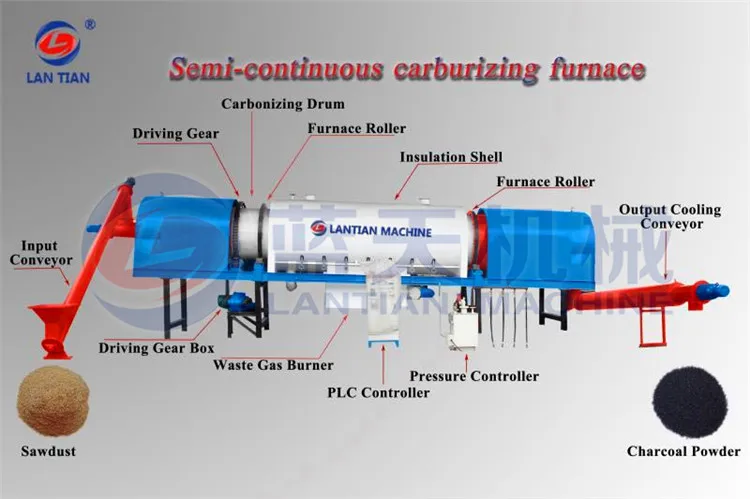

Automatic continuous carbonization equipment pass the carbonaceous lignin material such as wood chips, rice husks, peanut shells, plant straws and bark through the hammer pulverizer to a particle size of 5 mm or less, and then dried by a dryer or natural drying (the moisture requirement is less than 20%), and then through the process of drying, retorting, carbonizing, cooling, etc. of the drum carbonization furnace, the process of turning loose raw materials into desired charcoal.

Automatic continuous carbonization equipment use the destructive distillation method,take full advantage of CO,CH4,H2 etc combustible gas which produced by carbonizing process.Through the flue gas purification system, the wood tar acid solution was separated and the pure combustible gas was obtained,and then through the Self distribution air burner full combustion,to heat the high temperature carbonization pipes(the temperature controlled at 600-700℃).

Automatic continuous carbonization equipment has two layers of pipe from top to bottom,The first layer is pre heating and drying pipeline,the second layer is high temperature carbonization pipeline.The first layer is provided with an independent exhaust pipe which is mainly discharged water vapor,the pipe is dried by the heat of the waste heat in the furnace, and the water vapor is discharged from the exhaust pipe.The second layer is also provided with an independent combustible gas recovery pipeline.The first carbonization ignition source is supplied by the gas generator or diesel engine.

All kinds of biomass material: Fruit Husk,Wood Scraps, Sugarcane Bagasse, and Crop Stalks,

Friut Husk---Rice husk, Coconut shell, Peanut shell/ Groundnut shell, Sunflower seed husk/shell, Palm kernel shell, Walnut shell, Almond shell, Pistachio shell etc..

Wood Scraps---Wood sawdust,Forest farm & furniture factory scraps, Wood shavings, Wood chips, Tree branch, Bamboo scraps, Sugarcane bagasse, Distillers grains, Coffee grounds, coco husk chips, Waste from beer breweries, Empty Fruit Bunch etc.

Crop Stalks---Plants straw, Crop residues, Soybean straw, Wheat straw, Cotton straw, Corn stalks, Sorghum stalk, Maize Cob/ Corncob, Sorghum husk/ shell/hull, Potato grass, Dead leaves etc.

Usually inlet material size need less than 5mm, so you need crush them firstly if larger than 5mm.

The project we designed for different customers

Rotary dryer---continuous carbonization furnace---crusher---wheel mixer---hydraulic shisha charcoal machine---heat pump dryer

Continuous carbonization furnace---crusher---wheel mixer---hydraulic shisha charcoal machine---heat pump dryer

If unit set Automatic continuous carbonization equipment, it need around 15-20 days for installation, because not only it need build up water pool for purify the smoke, but also it need install and teach operation after finishing.

Below are our some customers working site in different countries, please check it.

Because of larger size, usually this Automatic continuous carbonization equipment will be loaded in 40HQ container.

Usually for 0.8*10m type. it need one 40HQ container for loading;

We are a factory more than 20 years, located in Gongyi city (mechanical city), Henan Province, China. More than 20 years dedicated development, we have own patented products, we have many customers from home and abroad, some even become our long term parters and agents. Good product quality and perfect after-sales service alwalys are our purpose, and guarantee to our customers.

These years, our products have exported to many countries, such as India, Indonesia, Tailand, Malaysia, Dubai, Russia, Uzbekistan, Africa coutries, Arab coutries, etc.

Our main products are briquette machine production line (shisha charcoal and bbq charcoal machine), dryer(rotary dryer, mesh belt dryer, heat pump box dryer), , carbonization furnace(continuous type, airflow type, horizontal type, nature type), crusher, conveyor belt, etc.

More than 20 years development, our customers already in many countries all over the world.

Indonesia, India, Malaysia, Singapore, Philippines, Thailand, Oman, Yemen, South Korea, Sri Lanka, Pakistan, Vietnam, Afghanistan, Uzbekistan, Kazakstan, Egypt, Algeria, Zambia, Tunis, Dubai, Lebanon, Peru, Agentina, USA, Mexico, Brazil, Russia, Etc.

Certificates

If any inquiry, please contact me!

Похожие товары

Биокарбонизация угля, ретортная печь

Бездымная Экологически чистая карбонизирующая печь для продажи

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com