Медицинский порошок FL гранулятор частиц сушильная машина с флюидированным

- Категория: Pharmaceutical Machinery >>>

- Поставщик: Jiangyin,Wantong,Pharmaceutical&,Chemical,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 4165.23 $* | 4373.63 $* |

| Aug-19-2025 | 4130.65 $* | 4337.77 $* |

| Jul-19-2025 | 3465.25 $* | 3638.82 $* |

| Jun-19-2025 | 4060.81 $* | 4263.98 $* |

| May-19-2025 | 3535.35 $* | 3712.58 $* |

| Apr-19-2025 | 3990.72 $* | 4190.45 $* |

| Mar-19-2025 | 3955.12 $* | 4153.38 $* |

| Feb-19-2025 | 3920.33 $* | 4116.24 $* |

| Jan-19-2025 | 3885.33 $* | 4079.26 $* |

Характеристики

FL boiling fluid bed dryer granulator drying equipment

Product Detail:

Main Uses: FL FLUID BED DRYER GRANULATOR

1.Phamaceutical industry: tablet, capsule, low sugar or no sugar granule of Chinese medcine.

2.Foodstuff: cocoa, coffee, milk powder, juice of granulate, flavoring and so on

3.Other industries: peticide, feed chemical fertilizer, pigment, dyestuff and so on

4.Pharmaceutical industry: tablet

5.Coating: grain,pill layer,slow-releasing,film inteatines dissolving coating etc.

Working Principal FL FLUID BED DRYER GRANULATOR

The powder grannle in the container(fluidization) appear in the state of fluidization.It is preheated and mixed with clean and heated air.At the same makes the solution of adhesive solvent is fogged and sprayed into the contaier.It makes the some particles become granulating that contains adhesive.Being of unceasing dry through hot qir,the moisture in the granulation is evaporated and the adhesive is solidification.The process is carries out continuously.Finally it forms ideal,uniform and Porous granules.

Feature: FL FLUID BED DRYER GRANULATOR

1.Because of powder granulation, the fluidity is improved and the dust is reduced

2.Because of powder granulation, its solving property is improved

3.The mixing, granulation and drying can be completed in one step indside the machine

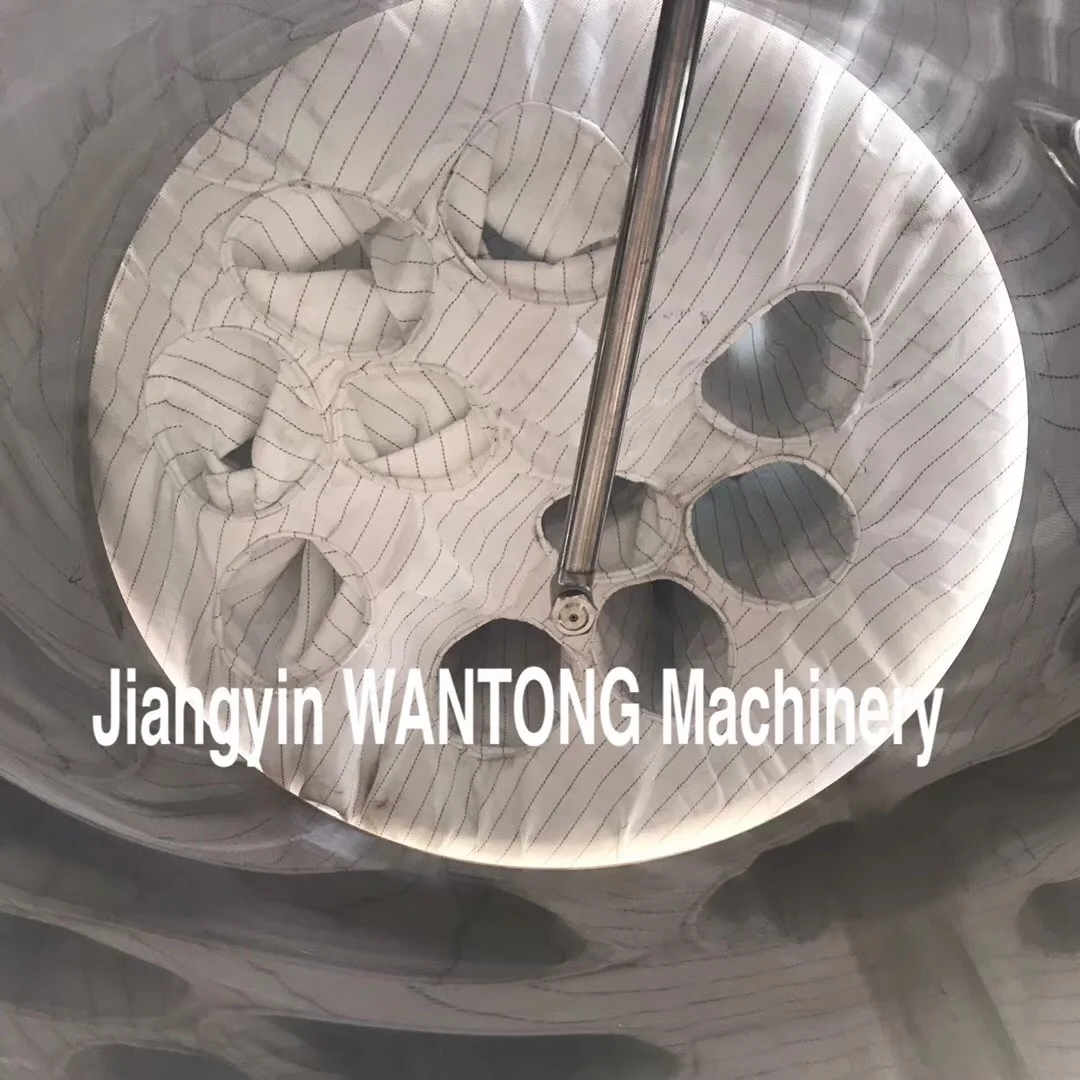

4.The operation of equipment is sage beacuse the anti static filtering cloth is adapted

5.The operating personnel can not be injured if explosion take place because there is releasing hole

6.The equipment has no dead corner. Therefore, the loading and unloading are quick, light and clean. It can meet the requirements of GMP

WHY CHOOSE YOU?

1; this machine is meeting ISO 9001 certificate

2: this machine is made up of stainless steel( we also can do as consumer requirement)

3: this machine is main used for make the granule, need to add the adhesive during make granule, The operation of equipment is safe because the anti static filtering cloth is adopted;

4; this machine can use steam or electric( consumer can select )

5: the voltage: 220V or 380V or as consumer requirement

6: guarantee: 1 year

7: deliver date: 30 days

8: payment: 30% TT in advance, 70% need to pay us before deliver goods

9: export port: shanghai port

FL FLUID BED DRYER GRANULATOR TECHNOLOGY DATA

Model 3 5 15 30 45 60 90 120 200 300 500

Volume(L) 12 22 45 100 155 220 300 420 660 1000 1500

Steam amount (KG/H) 0.5 1 2 6 7 10 15 20 40 70 100

1.Phamaceutical industry: tablet, capsule, low sugar or no sugar granule of Chinese medcine.

2.Foodstuff: cocoa, coffee, milk powder, juice of granulate, flavoring and so on

3.Other industries: peticide, feed chemical fertilizer, pigment, dyestuff and so on

4.Pharmaceutical industry: tablet

5.Coating: grain,pill layer,slow-releasing,film inteatines dissolving coating etc.

Working Principal FL FLUID BED DRYER GRANULATOR

The powder grannle in the container(fluidization) appear in the state of fluidization.It is preheated and mixed with clean and heated air.At the same makes the solution of adhesive solvent is fogged and sprayed into the contaier.It makes the some particles become granulating that contains adhesive.Being of unceasing dry through hot qir,the moisture in the granulation is evaporated and the adhesive is solidification.The process is carries out continuously.Finally it forms ideal,uniform and Porous granules.

Feature: FL FLUID BED DRYER GRANULATOR

1.Because of powder granulation, the fluidity is improved and the dust is reduced

2.Because of powder granulation, its solving property is improved

3.The mixing, granulation and drying can be completed in one step indside the machine

4.The operation of equipment is sage beacuse the anti static filtering cloth is adapted

5.The operating personnel can not be injured if explosion take place because there is releasing hole

6.The equipment has no dead corner. Therefore, the loading and unloading are quick, light and clean. It can meet the requirements of GMP

WHY CHOOSE YOU?

1; this machine is meeting ISO 9001 certificate

2: this machine is made up of stainless steel( we also can do as consumer requirement)

3: this machine is main used for make the granule, need to add the adhesive during make granule, The operation of equipment is safe because the anti static filtering cloth is adopted;

4; this machine can use steam or electric( consumer can select )

5: the voltage: 220V or 380V or as consumer requirement

6: guarantee: 1 year

7: deliver date: 30 days

8: payment: 30% TT in advance, 70% need to pay us before deliver goods

9: export port: shanghai port

FL FLUID BED DRYER GRANULATOR TECHNOLOGY DATA

Model 3 5 15 30 45 60 90 120 200 300 500

Volume(L) 12 22 45 100 155 220 300 420 660 1000 1500

Steam amount (KG/H) 0.5 1 2 6 7 10 15 20 40 70 100

-1 -3 -5 -15 -18 -23 -50 -60 -80 -150 -200

Processing Amount (KG/batch)

1.5 4 10 15 25 40 60 80 100 150 300

Processing Amount (KG/batch)

1.5 4 10 15 25 40 60 80 100 150 300

-4.5 -6 -20 -45 -65 -80 -120 -160 -300 -450 -700

steam Pressure(MPa) 00.4-0.6

Consumption(m3/min)

12 22 42 70 99 141 169 211 282 366 451

Compressed air Pressure(MPa) 0.6

Consumption(m3/min)

0.3 0.3 0.3 0.4 0.4 0.6 0.6 0.9 0.9 1.3 1.5

Temperature(°C) 0-120

Wind motor power(KW)2.2 3 4 5.5 7.5 11 15 18.5 22 30 37

Noise(Decibel) <75 (wind motor separated)

The above is our technical data. We can also design and manufacture different varieties upon customer's request.

steam Pressure(MPa) 00.4-0.6

Consumption(m3/min)

12 22 42 70 99 141 169 211 282 366 451

Compressed air Pressure(MPa) 0.6

Consumption(m3/min)

0.3 0.3 0.3 0.4 0.4 0.6 0.6 0.9 0.9 1.3 1.5

Temperature(°C) 0-120

Wind motor power(KW)2.2 3 4 5.5 7.5 11 15 18.5 22 30 37

Noise(Decibel) <75 (wind motor separated)

The above is our technical data. We can also design and manufacture different varieties upon customer's request.

OTHER RELATED PIC:

Company Profile

MORE MACHINE TYPE, INTO OUR WEBSITE: https://jywantong.en.alibaba.com

* More than 20 years old

* The big factory with rich experience and technology in Jiangyin

* Have many branches through the whole china.

* Own many honors, awards and certificates.

* Contact me by WHATSAPP or WECHAT, provide video/photos ALIVE.

* Our machine itself and our big factory will be our strongest and best explanations.

* We have many machines in the stock, we will be glad if you can visit us to get more real and effective information about the machine.

FOR MORE INFORMATION, PLEASE Click into Our Company

* The big factory with rich experience and technology in Jiangyin

* Have many branches through the whole china.

* Own many honors, awards and certificates.

* Contact me by WHATSAPP or WECHAT, provide video/photos ALIVE.

* Our machine itself and our big factory will be our strongest and best explanations.

* We have many machines in the stock, we will be glad if you can visit us to get more real and effective information about the machine.

FOR MORE INFORMATION, PLEASE Click into Our Company

NOTE: All machine photos are all true belong to us, without permission shall not be used without authorization !

contact us

PLEASE LET US BE MORE HONEST, THEN ANY QUESTION WILL BE REPLYED 100%SINCERELY AND VERY EFFCIENTLY BY CONTACTING ME.

Contact way in my company website https://jywantong.en.alibaba.com contact us page.

===>CONACT ME NOW FOR new and live videos/photos, talk to u in the VIDEO CALL !

Contact way in my company website https://jywantong.en.alibaba.com contact us page.

===>CONACT ME NOW FOR new and live videos/photos, talk to u in the VIDEO CALL !

STILL ON LOOKING FOR GOOD AND REAL MANUFACTURER IN CHINA?

MAY I INVITE YOU VISIT US?PLEASE. YOU ALREADY FIND US.

FL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipmentFL boiling fluid bed dryer granulator drying equipment