Автоматическая машина Zw-d для производства одноразовых печатных машин и бумажных

- Категория: Paper Production Machinery >>>

- Поставщик: Ruian,Daqiao,Packaging,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.58 $* | 0.63 $* |

| Aug-17-2025 | 0.49 $* | 0.45 $* |

| Jul-17-2025 | 0.33 $* | 0.61 $* |

| Jun-17-2025 | 0.17 $* | 0.40 $* |

| May-17-2025 | 0.41 $* | 0.56 $* |

| Apr-17-2025 | 0.84 $* | 0.64 $* |

| Mar-17-2025 | 0.40 $* | 0.90 $* |

| Feb-17-2025 | 0.72 $* | 0.50 $* |

| Jan-17-2025 | 0.20 $* | 0.59 $* |

Характеристики

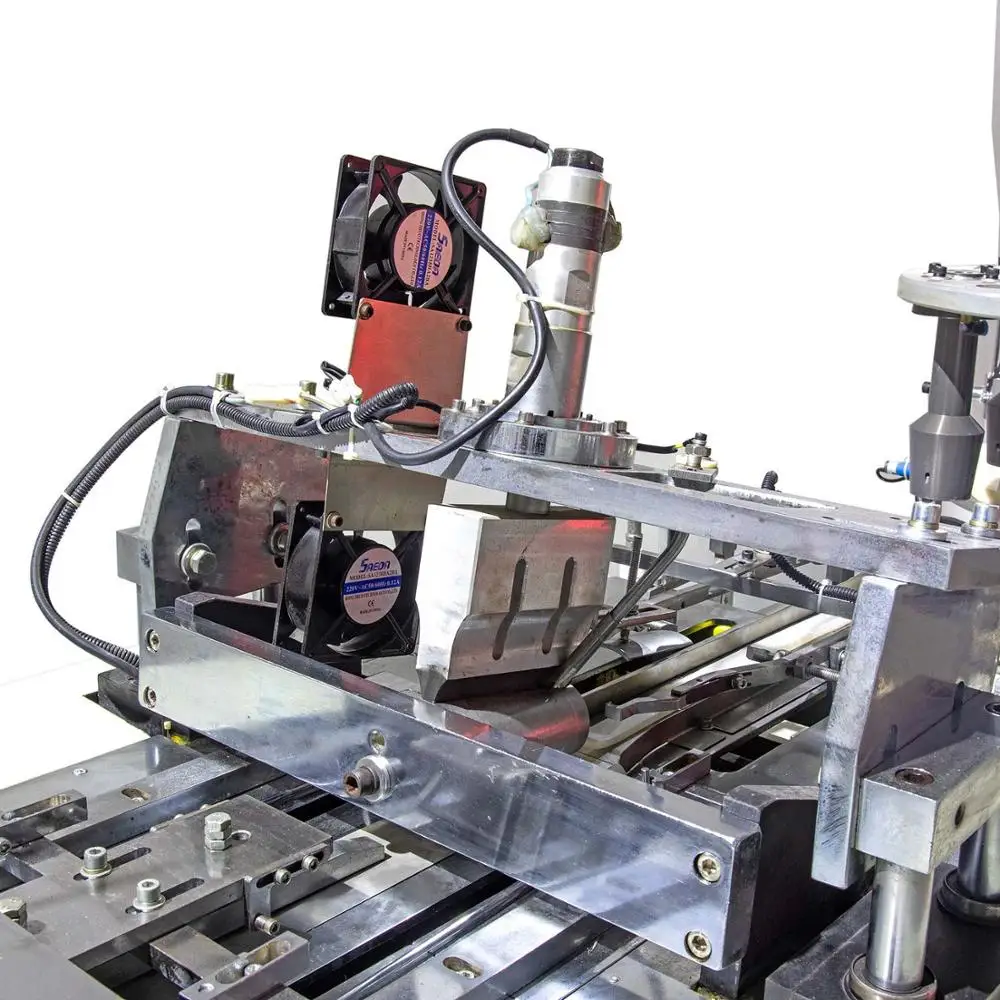

ZW-D paper bowl machine is the automatic environmental machine with multi-running positions. This machine runs a whole procedure of paper-feeding, cup-fan-wall sealing, oiling, bottom punching, heating, rolling, rimming, rounding and tripping. If you need double pe coated paper cups or paper gram higher 250kg, we recommend you to use Ultrasonic set, it can produce single pe coated paper cups and double pe coated paper cups.

Technical Specification:

Type: | ZW-D |

Cup size: | 20-50oz and others(different size mold exchanged) |

Suitable paper material: | 150-300g/m2(single or double PE-coated paper) |

Capacity: | 35-50pcs/min |

Power source:: | 220V,380V 50HZ(please inform us your power in advanced) |

Total power: | 6KW |

Weight: | 2200KG |

Package size: | 2900 x 1500 x 1800 mm |

Working Air Source: | Air pressure 0.4Mpa;Air out-put:0.6m3/min |

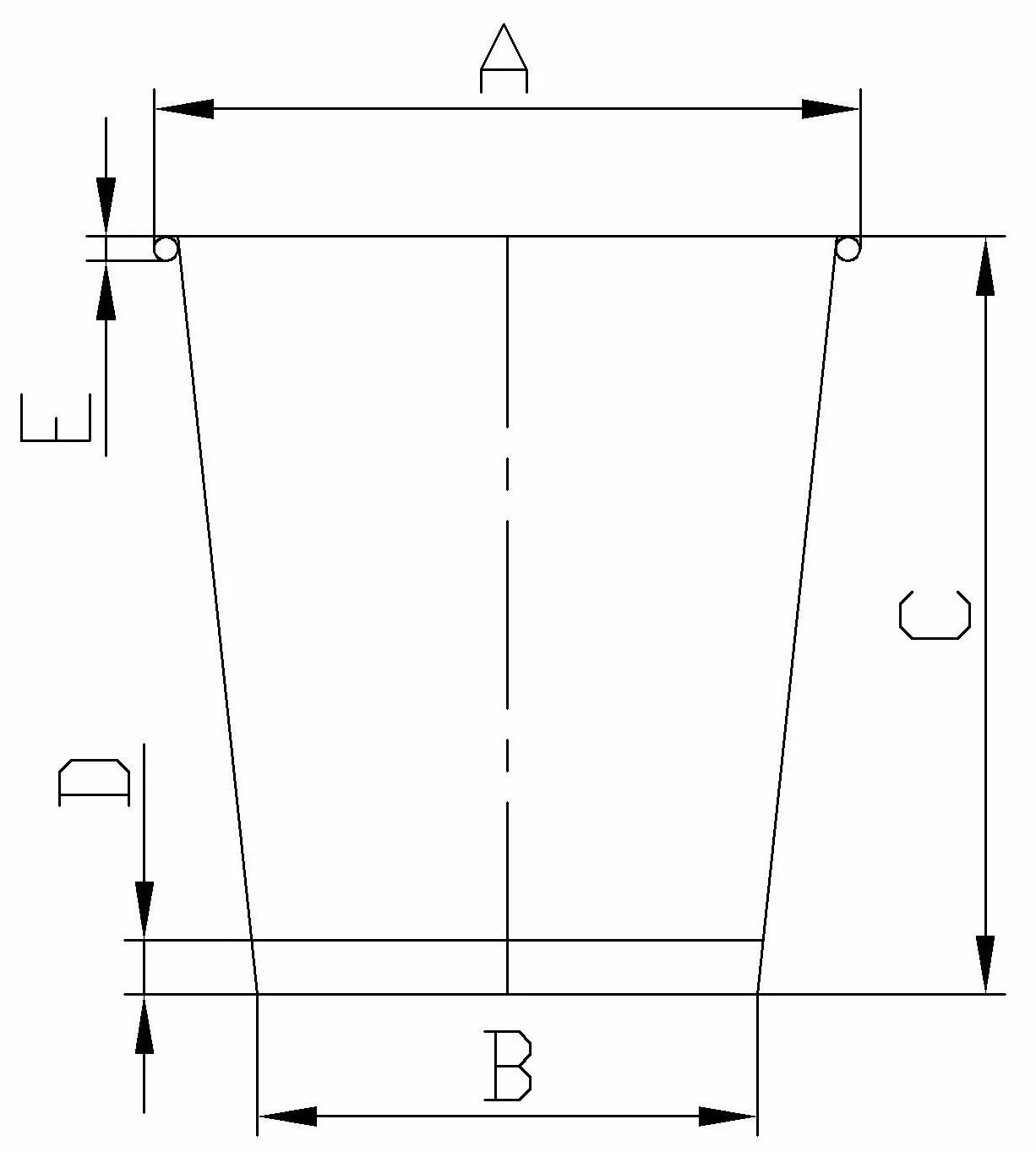

| A:top diameter: Min 80mm---Max 145mm B: bottom diameter Min 60mm---Max 110mm C: total height Min 30mm---Max 115mm D:bottom knurling depth Min 4mm---Max 12mm E:rim diameter Usually Φ2.5---Φ3 |

Advantage and improvement:

1.Use gear driving system instead of chain, more stable running and speed up.

2.Use automatic lubrication recycle system instead of oiling by hand to reduce the friction and wear between gears, improve the machine safety and reduce the cost of maintenance.

3. 100 type speed reducer is used instead 80 type.The speed reducer and the gear box are very important to the machine.They control the whole machine,if there are some problems with these two parts,then,you have to change the gear box and speed reducer.In this case,the machine should be taken apart,because they are inside the machine.It takes much time,and sometimes you cannot install the machine correctly.So it is necessary yo use better gear box and speed reducer.

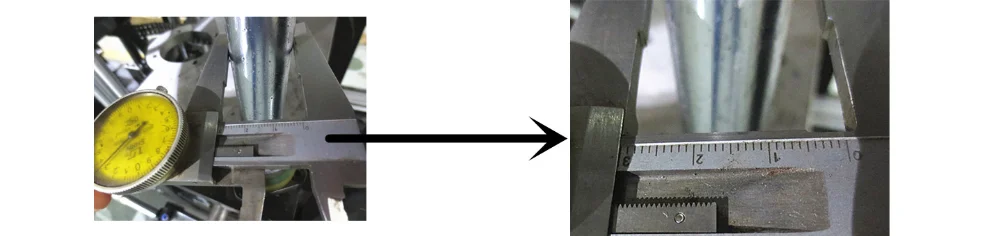

4.New design knurling wheel is used to guarantee the even pressure and better bottom sealing.

5.Cup folding parts is controlled by three separate cams,and each folding clip can be adjusted by itself.

6. Change the Ø25 normal steel shaft to Ø30 imported steel shaft to be sttrengthened,longer life and more stable.

7. Organ type sucker is used for cup fan sucked to gaurantee powerful sucking and more successful.The life is much more longer than normal sucker.

1.Q:Where is your factory? How can I get there?

A: We are located in Ruian City Wenzhou, Zhejiang Province.

To Wenzhou Longwan airport by Air, from Shanghai is about 45mins, from Guangzhou is about 1hr 50mins and from Hongkong is about 2hrs. We will pick up you in the airport.

2.Q:Can your machine be customized?

A: Your better improvement suggestions are highly appreciated. Almost all of our products can be customized, including the sizes, color, logo, package and so on.

3.Q :What's the OLD(order lead time)?

A: For our standard model machines is about 30days after receiving your deposit.

4. Q: How about your package?

A: Our machines are well wrapped by plastic film to be water proof first, then loading and fixing in a plywood case. If by FCL(full container loading) we might use the wooden pallet with plastic film wrapping, without plywood case.