Высокое качество автоматический 3D чпу сверлильный

- Категория: Сверлильные станки >>>

- Поставщик: Shandong,Alles,Energy,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 161840.0 $* | 169932.35 $* |

| Aug-19-2025 | 160480.30 $* | 168504.64 $* |

| Jul-19-2025 | 134640.87 $* | 141372.54 $* |

| Jun-19-2025 | 157760.12 $* | 165648.54 $* |

| May-19-2025 | 137360.56 $* | 144228.29 $* |

| Apr-19-2025 | 155040.34 $* | 162792.52 $* |

| Mar-19-2025 | 153680.28 $* | 161364.86 $* |

| Feb-19-2025 | 152320.59 $* | 159936.59 $* |

| Jan-19-2025 | 150960.50 $* | 158508.60 $* |

Характеристики

Detailed Images

◆The spindle all producted by ourselves

◆The Reducer researched, designed and producted all by ourselves

Product Description

Product Information:

CNC Beam Drilling Machine Processing Link:

https://youtu.be/As9xe2lvgDE

https://youtu.be/As9xe2lvgDE

CNC drilling machine is a precision machine tool with an integration of machinery, electricity, hydraulic pressure, and numerical control. The structural features are that a fixed crossbeam, mobile type gantry drilling and milling machine, with milling, drilling, tapping and different cutting functions. It has improved on the quality and efficiency of the manufacture.

CNC Beam drilling machine adopt CNC system centralized control, servo drive, transmission of gear and rack and linear roller rolling guide rail. It can realize the precise operation of the machine, thus reduces the worker labor intensity.

ALLES Service

Main Technical Parameters | ||||||||||

Name | Unit | Parameter values | Remark | |||||||

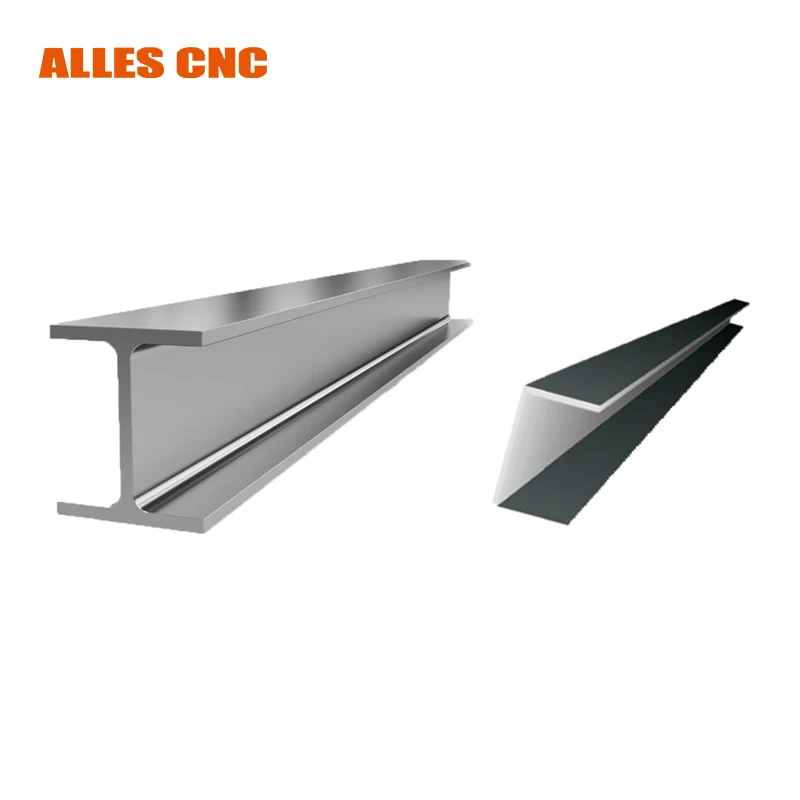

size | H Beam | mm | 150x75~1250x600 | |||||||

Thickness | mm | ≤80 | ||||||||

Length | m | 15 | By customer’s request | |||||||

Short-material restrictions | mm | Automatic processing ≥3000 | ||||||||

manual processing:690~3000 | ||||||||||

Spindle | numbers | unit | 3 | |||||||

Drill size | The fixed side and moving side | mm | ¢12.5~¢26.5 | |||||||

Intermediate unit | mm | ¢12.5~¢33.5 | ||||||||

Main shaft rotation speed | r/min | 180~560 | ||||||||

Main shaft taper | / | #3 and #4 Morse taper hole | Can turn into#2 | |||||||

Axial stroke | The fixed side and moving side | mm | 140 | |||||||

Intermediate unit | mm | 240 | ||||||||

Axis to the feed rate | mm/min | 20~300 | ||||||||

Moving distance | Each spindle in the direction of length of the workpiece | mm | 520 | |||||||

Both sides of the spindle in the vertical direction | mm | 35~570 | Start from upper planar of the supporting roller | |||||||

Intermediate unit in the direction 0f the workpiece width | mm | 45~1160 | Starting from datum side | |||||||

Cooling method | Compressed air + cutting fluid | / | / | |||||||

Air supply pressure | MPa | ≥0.5 | ||||||||

Processing accuracy | Hole group adjacent Pitch error | mm | ≤0.5 | |||||||

10 meters adjacent to the accuracy of the feeding distance | mm | ≤1 | ||||||||

Motor Power | Spindle rotation of three-phase asynchronous motors | kW | 4x3 | Spindle NO.: 3 | ||||||

Intermediate unit X-axis servo motor | kW | 0.85x2 | ||||||||

Intermediate unit Z-axis servo motor | kW | 1.3 | ||||||||

Fixed side , movable side X-axis servo-motor | kW | 0.85x2 | ||||||||

Fixed side , movable side Y-axis servo-motor | kW | 1.3x2 | ||||||||

The mobile pallet three-phase asynchronous motor | kW | 0.55 | ||||||||

Overall | L x W x H | mm | About 4800x2400x3300 | |||||||

total weight | kg | About 7500 | ||||||||

Measuring Machine

Honest Customer

Our Honour

Exhibition Show

Packing & Delivery