Экструдер для

- Категория: Plastic Granulators >>>

- Поставщик: Wedo,Machinery,(Zhangjiagang),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 34510.34 $* | 36236.57 $* |

| Aug-20-2025 | 34220.89 $* | 35931.53 $* |

| Jul-20-2025 | 28710.56 $* | 30146.38 $* |

| Jun-20-2025 | 33640.40 $* | 35322.5 $* |

| May-20-2025 | 29290.44 $* | 30755.95 $* |

| Apr-20-2025 | 33060.17 $* | 34713.67 $* |

| Mar-20-2025 | 32770.12 $* | 34409.98 $* |

| Feb-20-2025 | 32480.75 $* | 34104.49 $* |

| Jan-20-2025 | 32190.42 $* | 33800.55 $* |

Характеристики

PP PE HDPE scrap flakes waste plastic extruder, PP PE HDPE LDPE plastic flakes granulating pelletizing extruder machine line

Description:

HDPE plastic pelletizing machine designed with the actual application condition. This HDPE plastic pelletizing machine is specializes for recycling the recycled washed plastic PP HDPE rigid plastic flakes, such as plastic milk bottle flakes, shampoo bottle flakes, medicine bottle flakes, PE drinking bottle flakes, plastic basin flakes, plastic bucket flakes, etc.

After the processing of feeding, heating, melt, cooling, drying, cutting etc., the final products are HDPE plastic pellets/granules that can be to produce plastic chair, plastic profile, plastic bottle, drainage pipes, plastic sheet etc.

Overview of PP PE HDPE scrap flakes waste plastic extruder

Working Flow of PP PE HDPE scrap flakes waste plastic extruder:

Screw feeder → Efficient extruder → Non-stop hydraulic screen filter changer → (second stage extruder → hydraulic screen filter changer → die head →) Water cooling → Strand cutting → Blower → Storage hopper → Electric control panel

Pohotos of PP PE HDPE scrap flakes waste plastic extruder:

Screw loader

First stage single screw extruser ( mother extruder)

Non stope hydraulic screen changer

Second stage single screw extruder (baby extruder)

Die face cutting watering colling pelletizer die head

Vibrating machine

The main parts function in PP PE HDPE scrap flakes waste plastic extruder (canbe customizable)

1. Screw feeder: the first step of the pelletizing recycling machine, plastic scraps such as PP PE rigid washed flakes conveyed into the hopper through screw, the screw connect sensor to detect the material in hopper, once the flakes are full in hopper, the screw will stop; and once empty, the screw feeder will begin working.

2. Extruder: to plasticization and degassing, a specialized single screw extruder applied to melt the pre-compacted material. The plastic scraps will well melted, plasticized in the first stage extruder, and the plastic will be extrude by the second stage extruder. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with some water content.

3. Non-stop hydraulic screen filter changer: double stage filtering, fore filtering in the first extruder, and fine filtering in the second extruder, to reduce the frequency of filtering sieves changing. The requirements on the filter technology depend heavily on the quality of the input material as well as the planned use of granules.

4. Water cooling: made of 304 stainless steel, 4 meters length that fill with water, too cooling the melted plastic.

5. Cutting pelletizing: supplied with speed steel and hard alloy steel cutting blades for reliable performance. Compact structure allows less maintenance.

Parameters of PP PE HDPE scrap flakes waste plastic extruder:

CAPACITY | POWER CONSUMPTION | WATER CONSUMPTION | LABOUR | HUMIDITY CONTENT |

100-150 | 150 | Keep water cool | 1-2 | <2% |

250-300 | 200 | Keep water cool | 1-2 | <2% |

350-400 | 280 | Keep water cool | 1-2 | <2% |

450-500 | 360 | Keep water cool | 1-2 | <2% |

Advantage of PP PE HDPE scrap flakes waste plastic extruder:

Very low labor request.

Stable running.

Automatic constant temperature control.

CE certification, ISO9001 certification, SGS certification

Configuration based on client requirement and material, and give reasonable suggest.

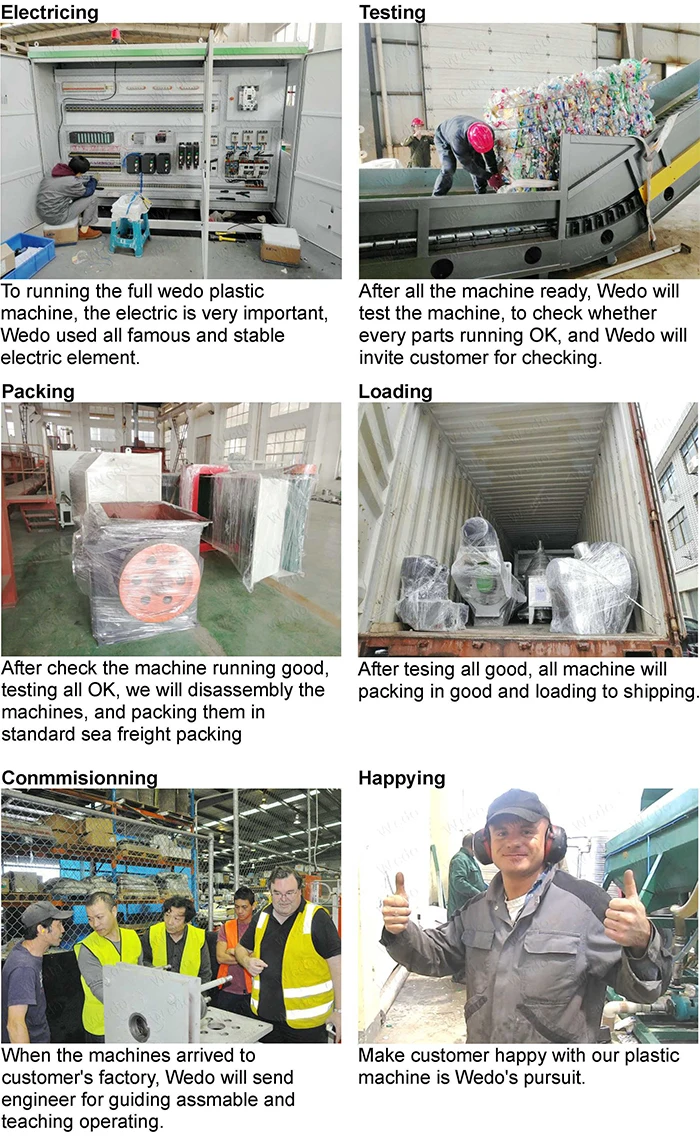

Wedo have a fully step for the PP PE HDPE waste flakes plastic pelletizer for sale producing before packing and shipping, this ensure the plastic recycling machine will delivery in good quality, and custerm will get good machine.

We do best service for you in PP HDPE scraps pelletizing machine for plastic recycling

Professional PP HDPE scraps pelletizing machine for plastic recycling factory

Wedo Machinery Co.,Ltd is specially for the plastic recycling machine and plastic extrusion machine. Wedo Machinery Co.,Ltd is continuously dedicates to the research & development and marketing of various types of plastic recycling machine and plastic extrusion machinery, PP HDPE scraps pelletizing machine for plastic recycling. The Customer is always enjoy the expertise and professional-made solutions offered by the companies in the group. Professional technology can guarantee our machine works on high level of innovation, durability and operational reliability.

Workshop

Office

We are professionally working for the plastic recycling machine and plastic extrusion machine in design, manufacturing, exporting and service, owning more than 15 years working experience. Our prouduct covers PP HDPE scraps pelletizing machine for plastic recycling, PET plastic bottle washing recycling machine, PET plastic flakes pelletizing granulator machine, PE PP plastic film washing recycling machine, PE PP plastic film pelletizing recycling machine, PP HDPE plastic bottle crushing washing recycling machinne, , PP PE plastic flakes pelletizing granulating recycling machine, waste plastic crusher machine, wide use single shaft shredder machine, double shaft shredder machine, PP PE pipe extrusion line, PVC pipe extrusion line, HDPE dimpled drainage sheet extrusion line, and related auxiliary machinery.

We Have Provided Our Machine To Many Plastic Product Enterprises Company In China And Other Countries In The Southeast Asia, Mid-East,South America,North America, Europe Union,Africa. Warmly Welcome The Friends From All The World To The Company And Develop Together And Create New Future.

Any more further about the PP PE HDPE scrap flakes waste plastic extruder, PP PE HDPE LDPE plastic flakes granulating pelletizing extruder machine line, please contact us timely, we will give your professional fully support.